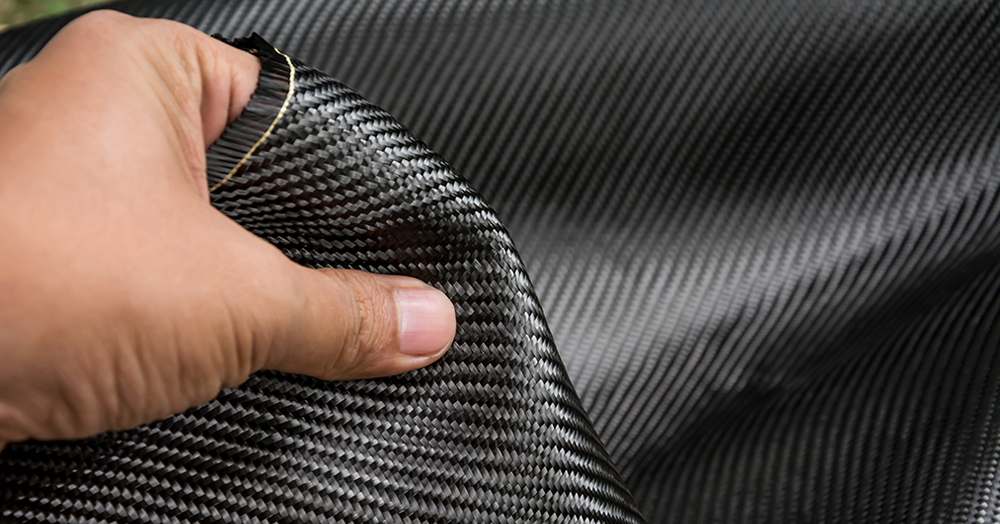

Carbon fiber is defined as a long thin strand of material which is made up of carbon atoms and has a diameter of about 0.005mm to 0.010mm. Such fibers provide high tensile strength along with high-temperature tolerance and durability. Carbon fibers possess excellent corrosion resistance, higher stiffness and strength, and longer lifespans than other materials, such as aluminum and steel. Hence, these fibers find their application in broad end-use industries. The fibers are rigid and chemically inert, which makes them difficult to compress and stretch. They provide high strength to the vessels, which helps prevent the explosions of gases storage systems. They are used in several applications such as aerospace & defense, automotive, construction and others. However, the high costs of carbon fiber manufacturing processes are limiting the market growth.

RISING DEMANDS FROM AUTOMOTIVE AND AEROSPACE APPLICATIONS TO BOOST ITS DEMAND IN THE GLOBAL MARKET

The automotive manufacturers are demanding new and innovative high-quality material for producing automotive components. These materials have to fulfill the high-performance need of automotive manufacturers and also meet the needs of the customer and society. Among the various materials, carbon fiber is considered as one of the most suitable materials for lightweight automobile parts. Moreover, the carbon-fiber-reinforced composites are used as the essential materials to substitute body and other parts in an automobile. The use of carbon fiber in the automobile industry has improved brake, steering, durability, and high fuel efficiency, leading to energy conservation and minimizing carbon dioxide emissions. Leading automotive manufacturers are using carbon fiber for manufacturing components. For instance, the Airbus A350 is 52 percent carbon fiber-reinforced polymer (CFRP) and the BMW i3 has mostly CFRP chassis. Carbon fiber is also used in high-end bike frames, tennis rackets and surfboards.

As carbon fibers offer high modulus and specific strength, fatigue strength, stiffness, and pressure-withstanding capacity; lower thermal expansion coefficient; corrosion resistance; and other beneficial properties; these are being widely used in the automotive and other industrial applications. These fibers are widely preferred over aluminum and steel. Also, the rising demands of lightweight materials, along with government initiatives to reduce the harmful gas emissions and increase fuel efficiency, is expected to drive the market for carbon fiber in automotive applications. The carbon fibers are widely used for transporting and storing liquefied and compressed natural gas in automotive applications, with major demands from North America, Europe, and APAC. Furthermore, carbon fiber is also used in the aerospace industry. Carbon fiber has high chemical resistance, tensile strength, stiffness, and low thermal expansion and weight properties which makes it suitable for aerospace application. It is used in designing, assembling, and manufacturing various types of aircraft. Over the past few years, the aerospace industry has switched from aluminum material to carbon fiber for the construction of the aircraft. Carbon fiber aircraft will burn and consume lesser amount of fuel due to its lightweight. Due to lesser fuel consumption, the aircraft will also have enough fuel left to cover long distances. These advantages of carbon fiber provide a lucrative opportunity for market players over the forecast period.