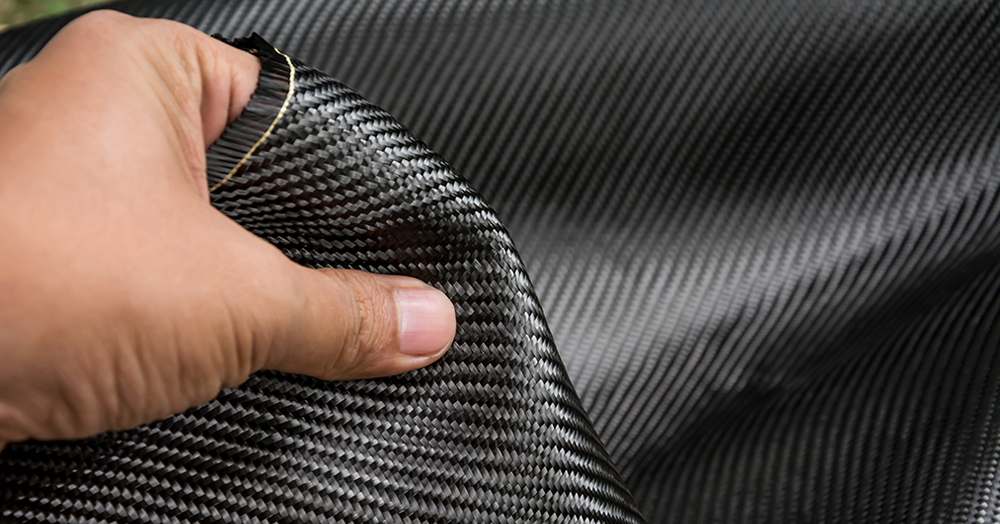

Composites are manufactured by combining reinforcements such as carbon fiber, glass fiber, aramid fiber, natural fiber, etc in matrix resin. The reinforcing material is incorporated in the form of as grainy material or particulates, as fiber or as layers. These engineered materials have several characteristics such as high strength/weight, modulus/weight ratios, high tensile strength and stiffness.

Glass fibers are thin strands of silica-based glass that are extruded into small-diameter fibers. Glass fibers are available in different compositions, namely A-glass, C-glass, D-glass, AR-glass, S-glass, and E-glass, with different properties and uses. These fibers are enclosed into a resin matrix to produce glass fiber-reinforced composites. Glass fiber-reinforced composites are polymerized monomer matrix that is filled by fine thin glass fibers, chemically bonded to that matrix using silane coupling agents. The higher utilization rate of glass fibers in end-use industries such as wind energy, construction, sporting goods, and marine has broadened the scope of glass fiber composites. The demand for construction composites is increasing with a rise in the use of technologically advanced processes in construction activities. Governments of various countries across the globe are significantly investing in infrastructure development in developed and developing nations through programs such as Saudi Vision 2030 and Abu Dhabi Economic Vision 2030. In November 2021, the US government approved a US$ 1.2 trillion infrastructure bill as an aid to federal investments in a wide range of infrastructure projects. Glass fiber composites are significantly used in marine applications for the design and manufacture of large composite structures. The major application of this composite in the marine industry is for bearings, propellers, commercial hatch covers, exhausts, and topside structures. The unique properties of glass fiber composites, including lightweight, high strength, a large degree of freedom of design, easy molding, low friction coefficient, and fatigue resistance, make it suitable for sports goods, and sports equipment, such as tennis rackets, golf clubs, bicycles, skis, and fitness equipment. Thus, the rising utilization of glass fiber composites in end-use industries is driving the composites market.

Some of the key players operating in the composites market are DuPont de Nemours Inc; Gurit Holding AG; Hexion Inc; Mitsubishi Chemical Holdings Corp; Nippon Electric Glass Co Ltd; Owens Corning; SGL Carbon SE; Teijin Ltd; Solvay SA; Toray Industries Inc; amongst few others. The major players in the composites market are focusing on strategies such as research and development and new product development to increase the geographical presence and consumer base.