The Surgical Gloves Market industry has a long history of growth. Several innovations have transformed the industry. This has made it to where it is today. Today, it will be quite odd to see a surgeon without surgical attire. Surgeons should not be operating on a patient without surgical gloves. However, it was in practice before the innovation of surgical gloves. Some of the earliest uses of doctor’s gloves or patients’ gown dates back to 1619. The Royal French physicians used gloves made of heavy leather. Some studies on surgical gloves direct us to the 17th century. To the plague pandemic to trace their earliest use. Surgical protective clothing studied by medical research experts. This is intended to unfold the historical records of disease transmission.

Surgical care has a crucial role in treating patients. Surgeons are alleviating patients’ sufferings. Surgery could be curative or preventive. It’s a component of acute emergency. The rise in chronic diseases demands intensive surgical procedures. The surgical need is estimated to remain high in the future. This is an indicator of growth in surgical equipment.

“Surgical Attire” got attention from all physicians. Surgical gloves are recognized as surgeons’ gloves or surgeon gloves. Surgical gloves and gowns follow medical standards. Protection of patients and doctors against infection is the key intent. Surgical cloths are made with adherence to surgical room standards.

Work safety needs drive innovation in surgical attire. They are meant to prevent the transmission of diseases. Clean surgical attire reduces the risk of bacterial filth. Medical research found disposable gloves effective in reducing infections. Surgical gloves act as a protective hindrance. The stringent medical hygiene standards drive sales of surgical gowns.

The growing aging population increased the demand for hospitals. The high spread of chronic health conditions has spurred surgical procedures. There has been an increase in medical surgeries among elders. As per WHO, the population above age 60 will grow from 12% to 22% by 2050. This could increase demand for surgical processes. Many Surgeons have started planning to manage the extra workload. There have been alterations in operating room protocols. The standard of attire worn by orthopedics and anesthetists. These are expected to upgrade surgical procedures. This has led to a rise in surgical gloves sales.

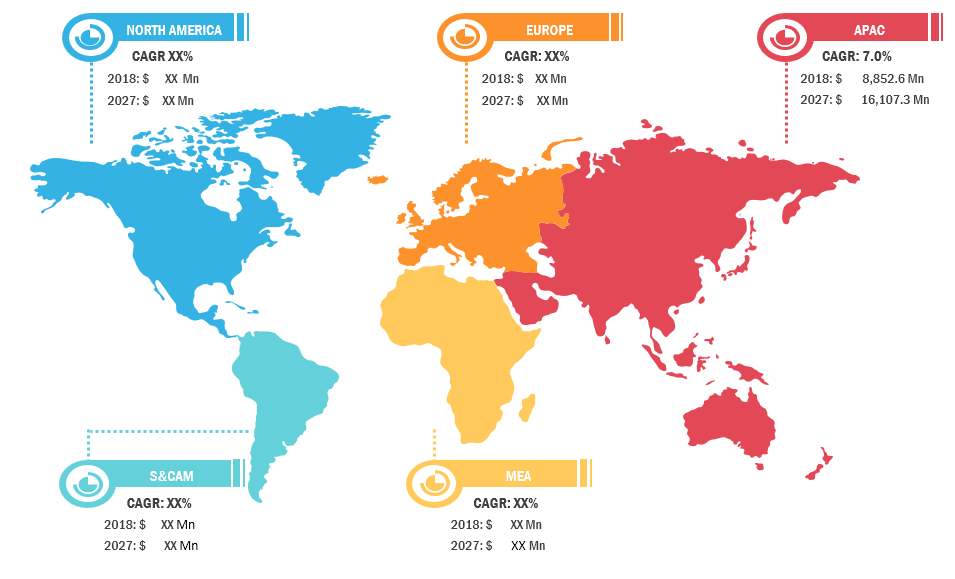

The progress in fabric material technology is the driver of the industry. Medical protective clothing is expected to grow. Especially for gloves, PPE, and gown segments. As per Insight Partners, the Global surgical glove market was valued at USD 2,292.03 million in 2019. It is expected to grow and surpass the valuation of USD 5,028.07 million by 2027.

Healthcare specialists treat critical patients in Intensive Care Units. At these places, most Healthcare-Linked Infections are contracted. Operating surgeons get exposed to blood-borne pathogens. To avoid any infections during surgery, the first defense is gloves. Gown and eyewear are some more protective shields. There is a gradual growth in the adoption of strict measures government. Legal strictness has created a demand for surgical gloves. Patient attire is important along with surgeons. As per Insight Partners, the global hospital gown market was valued at USD 2,620.88 Million in 2019. The industry is expected to grow with a CAGR of 7.2% in 2020- 2027. Hospital gowns are manufactured to provide comfort to patients.

COVID-19 has seen a surge in single-use shredded nitrile surgical gloves. The demand for surgical gloves increased. The repeated lockdown affected the supply chain. The pandemic created a windfall for leading surgical glove companies. The space captured by Malaysian companies. Malaysia remained a powerhouse for surgical gloves during 2021. The region accounted for a $28 billion valuation. Malaysian companies benefited during the pandemic. It was due to the shift in preferences of US people. They shifted from Chinese vendors to Malaysian vendors.

Australia and New Zealand noticed a gradual rise in market share. North America’s Top Glove remains the largest producer in 2022. The company has captured 26% of the rubber glove market share.

Companies improving size, material, and categories in Surgical Gloves Market.

There is a rapid surge in demand for Non-woven PPEs. It was when nitrile and synthetic gloves witnessed great demand. Some leading producers offer custom surgical gloves. These offer better precision. These gloves are available in powdered and powdered-free forms. The powdered material is used as a lubricant. Nigerian companies even offer disposable plastic gloves. They are easy to use and cost-effective. Plastic Surge Industries Pvt. Ltd. is producing reusable surgical gowns. The company is the leading medical robe producer in Nigeria. These are designed and crafted to offer comfort and convenience. Many companies offer custom hospital gowns with tags and logos. Comfort is a key factor in surgical attire. Moisture management of surgical clothing is important. Polyester-carbon offers desirable results.

Surgical Gloves Market Challenges that hinder companies’ capacity

The material cost plays a key role in the cost of the final product. The high cost of rubber latex creates a challenge for companies. Innovations such as anti-microbial gloves seem promising here. As they offer protection. Their cost is a barrier to adoption. These factors create challenges for companies. They struggle to tackle price and governing concerns at the same time.

Producers of gloves have to abide by stringent quality regulations. Each pair of surgical gloves needs separate packaging. Companies need to ensure the product is sterile. When compared to medical audit gloves, surgical gloves have more precision. The size of the glove has an impact on precision. Chemicals in contact with the glove impact its shelf life. Producers need to pay attention to the aforesaid issues.

Advanced robotics technologies have enabled safer operations. Surgeons can operate on patients with the help of robots. Robotic surgeries turning effective and time-saving. This is likely to affect the need for operating room labor. Robotic surgeries have reduced the need for regular surgical gowns. These gowns will be resigned to accommodate robotic arms inside. This trend is likely to restrain the market in the upcoming period.

The high cost of raw materials hinders textile production. Automated production has addressed labor cost issues to some extent. Textile processes produce high solid waste. This contributes to chemical hazards. Companies have to address these challenges. Investment in research can assist companies in this regard. High-tech upgrades could be effective. Companies acting on carbon footprint are likely to attract conscious consumers.

Plant-Based Gloves for Hands Holding Sustainable Future.

Medical waste is an emerging issue linked with faulty practices. Lack of disposal and cleansing creates risks. Reuse of medical waste reviewed by experts. In addition, companies need to ensure endurance. Top surgical glove companies are focusing on their carbon footprint. They are investing in plant-based or bio-based materials. Plant-based cast polythene gloves offer more protection and hygiene. These are available at affordable prices.

Companies have space to develop recyclable materials. Materials that are cost-effective as well as durable. Expansion of options can help companies tackle the demand. Cranfield Institute did research in partnership with Meditech Gloves. It has shown energy savings with natural rubber gloves. In addition, protein-free is seen as effective. Natural rubber degrades 100x faster than synthetic rubber. It’s limited to avoid skin allergies. The research further highlights, that about 50% of energy and time are saved due to changed processes. The change in latex formulation proved effective. They could help in erasing protein allergy problems. It will result in faster surgical glove production.

Reusable patient gowns are more sustainable than disposable gowns

Climate change has gained attention across industries. Companies are moving to substantial endurance. Textiles and Apparel have an impact on climate throughout the product lifecycle. Businesses need to make the right decisions referring to green balance. Life cycle assessment tools are available to help companies.

American Reusable Textile Association surveyed surgical gowns. The survey found reusable gowns sustainable over disposable. It’s expected that more reusable gowns spotted in the coming years. Reusable textiles are seen to have a long life span. They have high tensile strength and better bacterial protection. Reusable gowns can be more efficient from nature’s perspective. Polyester fibers are bio-degradable materials used for gowns. Disposable gowns will need more raw material. They create solid waste in large amounts. Disposable gowns could increase inventory size.

Future Surgical Glove and Hospital Gown Industry Outlook

- Research and Material Innovation

Thinking of what might go well for companies in the future? Well, it could be Research and Innovations in the material. Innovations in spraying and dipping. The use of aerosolized protective materials will be safe. It could be innovations such as reusable hospital gowns. In addition, bio-based gloves.

We can expect Smart gloves with embedded trackers. Innovations like smart gloves could take surgeries to the next level. Businesses can source raw materials from diverse places. This can ensure a continuous supply. Regional planning could be a key. They can tackle natural, political, and other hindrances. Producers are likely to get benefits out of the global supply chain. They need to ensure integrated quality checks.

- Strategic Concert and Finding New Revenue Streams

Over time surgical attire has evolved in terms of codes. It is expected to unfold many prospects. The industry is expected to achieve milestones. Top companies in this sector have grabbed the trends. They have initiated actions. Companies focused on streamlining their investments in developing countries. Strategic partnerships opted by them. Investment in high product-specific research are key strategic move. These have proven effective for a competitive edge.