Rising Demand from Wind Energy Sector Supports Advanced Composites Market Growth

According to our latest study on "Advanced Composites Market Forecast to 2028 – COVID-19 Impact and Global Analysis – by Fiber Type, Matrix Type, and End-Use Industry," the advanced composites market was valued at US$ 38,772.87 million in 2022 and is expected to reach US$ 69,092.18 million by 2028; it is estimated to record a CAGR of 10.1% from 2022 to 2028.

Advanced composites are made by combining reinforcements such as fiberglass, carbon fiber, and aramid fiber with a matrix such as thermoplastic resin, thermoset resin, and other matrices. The most common thermosets for advanced composite matrices are epoxies, phenolics, cyanate esters, bismaleimides (BMIs), and benzoxazines. Advanced composites are manufactured depending on the properties, shape, and volume needed for the application. A few common methods for advanced composites manufacturing are pultrusion, resin injection, resin transfer molding (RTM), and filament winding. Advanced composites have an exceptional strength-to-weight ratio, high stiffness, durability, and resistance to corrosion, chemicals, and environmental exposures.

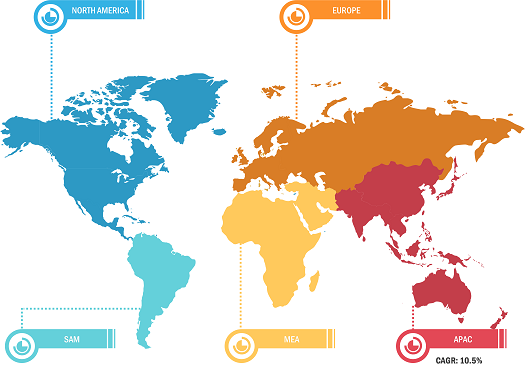

Advanced Composites Market Breakdown – by Region

Advanced Composites Market Forecast to 2028 - Global Analysis By Fiber Type (Carbon Fiber Composites, Aramid Fiber Composites, Glass Fiber Composites, and Others), Matrix Type [Epoxy Resin, Phenolics, Polyester Resin, Polyurethane Resin, Polyphenylene Sulfide (PPS), Polyetherimide (PEI), and Others], and End-Use Industry (Aerospace & Defense, Automotive, Wind Energy, Building & Construction, Electrical & Electronics, and Others)

Advanced Composites Market Strategic Insights by 2028

Download Free Sample

Advanced composites are crucial for the safety and efficient performance of modern aircraft. The increasing need for lightweight materials to construct aviation components and parts has significantly increased the demand for advanced composites. Aircraft manufacturers are making efforts to develop huge primary thermoplastic structures in business jets and commercial aircraft. They were the early adopters of long fiber-reinforced thermoplastics. Materials such as composites and polymers are significantly lighter than steel, brass, alloys, iron, etc. The use of these materials allows manufacturers to lower the weight of airplane parts, subsequently facilitating fuel cost reductions. These factors are driving the advanced composites market growth.

Avient Corp, Toray Industries Inc, Teijin Ltd, Mitsubishi Chemical Corp, SGL Carbon SE, Owens Corning, Solvay SA, Johns Manville Corp, Tecnaro GmbH, and Ensinger GmbH are a few of the key players operating in the advanced composites market. These companies have a diverse geographic presence and offer an extensive product range to address consumer demands.

Impact of COVID-19 Pandemic on Advanced Composites Market

Industries such as automobiles, aerospace & defense, building & construction, electrical & electronics, and wind energy have been the major contributors to the demand for advanced composites. In 2020, these industries had to slow down their operations due to disruptions in value chains caused by the shutdown of national and international boundaries. The COVID-19 pandemic hampered the major raw material supply chains and disturbed manufacturing processes due to restrictions imposed by government authorities in various countries. Furthermore, lockdown measures also impacted the availability of laborers, which hampered the production of advanced composites. Various advanced composites manufacturers had to temporarily suspend their operations or limit their production capacities, which negatively impacted the advanced composites market. However, in 2021, economies gradually resumed their operations, which positively affected the global marketplace. As large percentages of people from many countries were completely vaccinated by the end of 2021, manufacturers were permitted to operate at full capacities, which helped them consolidate their efforts toward closing the demand and supply gap. In addition, demand from various end use industries such as aerospace & defense, building & construction, automotive, and wind energy is increasing. These transformations helped them focus on scaling up their production to revive their businesses.

The report segments the advanced composites market as follows:

Based on fiber type, the advanced composites market is categorized into carbon fiber composites, aramid fiber composites, glass fiber composites, and others. Based on matrix type, the market is segmented into epoxy resin, phenolics, polyester resin, polyurethane resin, polyphenylene sulfide (PPS), polyetherimide (PEI), and others. Based on end-use industry, the advanced composites market is segmented into aerospace & defense, automotive, wind energy, building & construction, electrical & electronics, and others. Based on geography, the advanced composites market is segmented into North America, Europe, Asia Pacific (APAC), the Middle East & Africa (MEA), and South & Central America.

Contact Us

Phone: +1-646-491-9876

Email Id: sales@theinsightpartners.com