Increasing Demand for Lightweight Materials in Automtive Industry

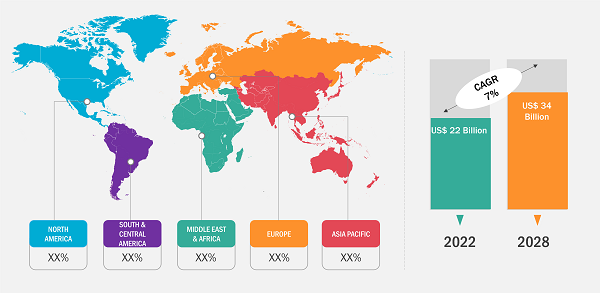

According to our latest market study on "Automotive Composite Market Forecast to 2028 – COVID-19 Impact and Global Analysis – by Fiber Type, Resin Type, Application, Vehicle Type, and Geography," the market is expected to grow from US$ 22 billion in 2022 to US$ 34 billion by 2028; it is estimated to record a CAGR of 7% from 2022 to 2028.

Automotive Composite Market Size and Forecasts (2021 - 2031), Global and Regional Growth Opportunity Analysis, and Geography (North America, Europe, Asia Pacific, and South and Central America)

Automotive Composite Market - Size and Forecast [2025-2031]

Download Free Sample

A few benefits of composites in automotive applications are cost reduction, weight reduction, and recyclability. Composites offer structural and weight advantages over traditional steel and injection-molded automotive parts. Advanced materials are crucial for boosting the fuel economy of modern automobiles while ensuring safety and performance. Since lighter objects consume less energy for acceleration than heavier ones, lightweight materials offer excellent potential for increasing vehicle efficiency. Substituting cast iron and traditional steel components with lightweight materials such as high-strength steel, aluminum (Al) alloys, magnesium (Mg) alloys, carbon fiber, and polymer composites can reduce the weight of a vehicle body and chassis by up to 50%, thereby reducing the fuel consumption of a vehicle. Compared to thermoset composites, thermoplastic materials offer more advantages to the automotive industry such as zero-solvent emissions, reduced material scrap, and improved work safety conditions.

Plastic composites have excellent acoustic and thermal properties compared to composites of nonrenewable origin, which makes them ideal for vehicles’ interior parts. Moreover, they are suitable for manufacturing nonstructural interior components, including seat fillers, seat backs, headliners, interior panels, and dashboards.

Electric vehicles (EVs) are the most attractive segment in the automotive industry. The utilization of composites for the design of EVs will boost the automotive composite market growth in the future. Each composite material type offers various benefits to auto designers in terms of production cost, manufacturing efficiency, and weight reduction. Also, composites help in improving thermal management, saving space near batteries, and increasing impact resistance. Therefore, the high demand for composites from the automotive industry for the manufacturing of fuel-efficient and lightweight vehicles drives the automotive composites market growth. The rising adoption of electric vehicles (EVs) is also expected to fuel the demand for composites in the industry during 2022–2030.

Toray Industries Inc., SGL Carbon, TEIJIN LIMITED, Mitsubishi Chemical Corporation., Hexcel Corporation, John Manville Corporation, Owens Corning, Zoltek Carbon Fiber, Cytec Solvay Group, and Gurit are among the key automotive composite market players profiled during the study. Several other major companies were studied and analyzed during this research study to get a holistic view of the market and its ecosystem.

Contact Us

Phone: +1-646-491-9876

Email Id: sales@theinsightpartners.com