Growth of Semiconductor Industry Drives Global Electronic Chemicals Market Growth

According to the latest market study on “Global Electronic Chemicals Market Analysis and Forecast to 2030 – Global Analysis – by Product Type and End Use," the market was valued at US$ 46,358.95 million in 2022 and is expected to reach US$ 76,383.14 million by 2030; it is estimated to register a CAGR of 6.4% from 2022 to 2030. The report highlights key factors driving the market growth and prominent players along with their developments in the market.

The electronics industry utilizes a wide range of specialty chemicals such as CMP slurries, solvents, surfactants, photoresist chemicals, wet chemicals, and acids for the manufacturing of electronic components and products, including silicon wafers, printed circuit boards, and integrated circuits. Electronic components are used in many industries, such as automotive, consumer electronics, telecommunication, and energy storage systems. The growing consumption of integrated circuits and development in the semiconductor industry, supported by government policies is boosting the global electronics industry, subsequently driving the electronic chemicals market. The global electronic chemicals market size is likely to surge by 2030 owing to the emerging applications in renewable energy.

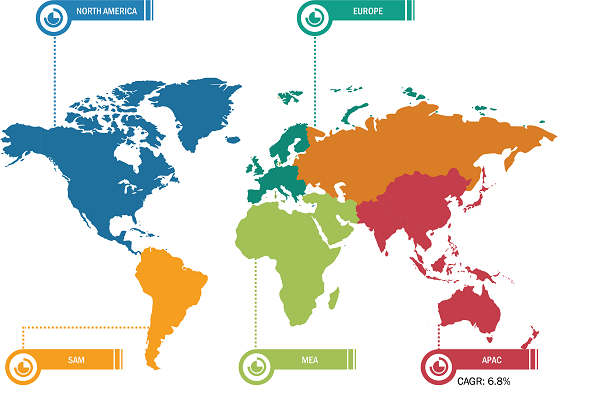

Global Electronic Chemicals Market Breakdown – by Region

Electronic Chemicals Market Size and Forecast (2020 - 2030), Global and Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Product Type (CMP Slurries, Photoresist Chemicals, Wet Chemicals, Acids, and Others) and End Use (Semiconductors, Flat Panel Displays, Printed Circuit Boards, Photovoltaics, and Others)

Electronic Chemicals Market Trends and Scope by 2030

Download Free Sample

Major factors driving the market growth are the expanding semiconductor industry and rising demand for flat-panel displays. The semiconductor industry is witnessing considerable growth owing to the increasing demand for electronic devices and the proliferation of emerging applications such as artificial intelligence, Internet of Things, and automotive electronics. As a result of continuous innovation, semiconductor technology has evolved rapidly in the past few years, enabling the development of small, fast, and energy-efficient chips with better processing capabilities. Furthermore, the growing focus on technological advancements in semiconductor manufacturing contributes significantly to the electronic chemicals market growth. Additionally, flat-panel displays such as liquid crystal displays, organic light-emitting diode displays, and microLED displays require sophisticated manufacturing processes that rely on electronic chemicals. These chemicals are used for cleaning, patterning, coating, encapsulation, and surface treatment steps to fabricate various layers and components of flat-panel displays. Cleaning agents such as solvents, surfactants, and etchants are used to remove contaminants, particles, and residues from glass substrates and semiconductor layers. Thus, the automotive industry is contributing to the growing electronic chemicals market size.

The global electronic chemicals market trends include the adoption of nanotechnology in electronic devices. Nanotechnology has enabled the development of nanoelectronic devices and components, such as nanoscale transistors, nanowire-based sensors, Organic light-emitting diodes, electronic paper, and quantum dot displays. These nanoelectronic devices have the potential to overcome the drawbacks of conventional silicon-based electronics and offer a promising future for sensor technology.

Fujifilm Holding Corp, Solvay SA, BASF SE, Linde Plc, Honeywell International Inc, Songwon Industrial Co Ltd, Hitachi High-Tech Corp, RBP Chemical Technology Inc, PVS Chemical Solutions Inc, and Esprix Technologies LP are among the prominent players profiled in the electronic chemicals market report. In addition, several other players have been studied and analyzed during the study to get a holistic view of the market and its ecosystem. The electronic chemicals market report also includes company positioning and concentration to evaluate the performance of competitors/players in the market.

The report aims to provide an overview of the market with detailed market segmentation. The market is segmented on the basis of product type and end use. Based on product type, the market is segmented into CMP slurries, photoresist chemicals, wet chemicals, acids, and others. The wet chemicals segment accounts for the largest electronic chemicals market share. Wet chemicals encompass a wide range of solutions and formulations tailored to specific applications, including cleaning, etching, stripping, and surface modification processes. One of the primary uses of wet chemicals is wafer cleaning, where they remove contaminants, residues, and particles from semiconductor surfaces to ensure optimal device performance and reliability. Cleaning solutions may include acids, bases, organic solvents, surfactants, and chelating agents, carefully formulated to target specific contaminants while minimizing damage to sensitive materials. Etching is another essential process facilitated by wet chemicals, whereby materials are selectively removed from semiconductor substrates to create intricate patterns and features. Wet etching solutions typically consist of acids or bases that selectively dissolve certain materials while protecting others through the use of masks or patterning techniques. Wet etching enables the precise definition of device structures, such as transistor gates and interconnects, in semiconductor fabrication.

Chemical mechanical planarization (CMP) slurries are also fundamental components within the electronic industry's manufacturing processes, particularly in semiconductor fabrication. Their primary function is to achieve precise and uniform polishing of semiconductor wafers, ensuring optimal surface flatness, smoothness, and layer thickness uniformity. CMP slurries are complex formulations comprising abrasive particles, typically silica or alumina, suspended in a chemical solution. These slurries are meticulously engineered to balance mechanical abrasion with chemical interactions, facilitating the removal of unwanted materials from the wafer surface. The chemical constituents of CMP slurries often include acids, bases, surfactants, and complexing agents, which serve multiple purposes, such as controlling the pH level, enhancing particle dispersion, and promoting selective material removal.

Based on end use, the market is segmented into semiconductors, flat panel displays, printed circuit boards, photovoltaics, and others. The semiconductors segment accounts for the largest electronic chemicals market share. Electronic chemicals play a vital role in the semiconductor industry, where their precise application is important for achieving optimal performance and reliability of semiconductor devices. Throughout the fabrication process, a diverse range of chemicals is employed to manipulate the properties of semiconductor materials, primarily silicon. Acids such as hydrochloric acid (HCl) and nitric acid (HNO3) are utilized for cleaning and etching silicon wafers, ensuring the removal of impurities and uniform surface preparation. Dopants such as boron, phosphorus, and arsenic are introduced into the silicon lattice to modify its electrical conductivity, which is crucial for controlling the behavior of transistors and other electronic components. During photolithography, photoresists, developers, and etchants are used to define intricate patterns on semiconductor surfaces, enabling the precise fabrication of transistor structures and interconnections at nanoscale resolutions. Encapsulation materials such as epoxy resins and silicone gels provide protective coatings, shielding semiconductor components from environmental factors, moisture, and mechanical stress.

Flat panel displays, such as televisions, computer monitors, or smartphones, rely on a complex combination of materials and technologies, with electronic chemicals playing a crucial role at each step of the manufacturing process. One key application of electronic chemicals in flat panel display production is in the fabrication of thin-film transistor (TFT) arrays, which serve as pixel-switching components. Acids such as hydrochloric acid (HCl) and sulfuric acid (H2SO4) are used for cleaning and etching the glass substrates, ensuring optimal adhesion and uniformity for subsequent layers. Photoresists, developers, and etchants are then employed during photolithography processes to define the intricate patterns of TFTs and interconnections with micron-level precision. For example, indium tin oxide (ITO) is a transparent conductive material used as electrodes in touchscreens and liquid crystal displays (LCDs). Electronic chemicals are used in the deposition and patterning of ITO films, ensuring high conductivity and transparency.

Contact Us

Phone: +1-646-491-9876

Email Id: sales@theinsightpartners.com