Surging Automotive Production Fuel North America Welded Steel Tubes Market Growth

According to our latest market study on "North America Welded Steel Tubes Market Size and Forecast to 2031 – Regional Analysis – by Steel Grade, Application, Type, and Coating Type," the North America welded steel tubes market was valued at US$ 39.36 billion in 2023 and is expected to reach US$ 59.36 billion by 2031; it is anticipated to register a CAGR of 5.3% from 2023 to 2031. The North America welded steel tubes market report includes growth prospects in light of current trends and driving factors influencing the market growth.

Welded tubing is made by rolling strips of steel into a tube and then welding the entire length. After welding, the weld seam, or bead, can be refined using cold rolling and forging techniques or left in its original form. Cold forming produces smoother finishes with tighter tolerances. Welded tubing can even be drawn such as seamless tubing, resulting in a better weld seam and surface finish. Welded tubing can also be produced with thinner walls on larger diameter tubes than seamless tubing. Welded tubing is typically faster to produce and less expensive than seamless tubing due to its reduced processing requirements. All these features boost the use of welded tubing, which fuels the North America welded steel tubes market growth.

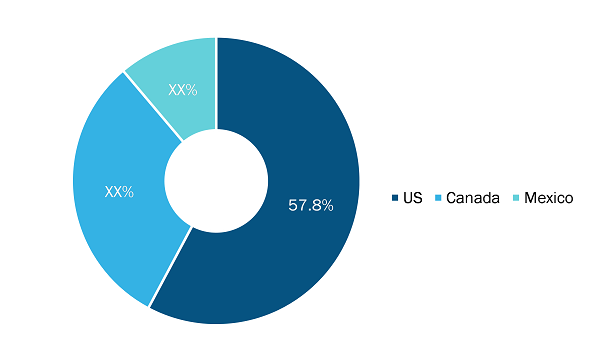

North America Welded Steel Tubes Market Share — by Country, 2023

North America Welded Steel Tubes Market Size and Forecast (2021 - 2031), Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Steel Grades (Carbon Base Grades, Boron Grades, Alloy Grades, HSLA, AHSS, and Others), Application (Exhaust, Automotive, Appliances, Medical Devices, HVAC, Burner, Conveyor Belts, and Others), Type [Electric Resistance Welding (ERW), Longitudinal Submerged Arc Welding (LSAW), and Spiral Submerged Arc Welded (SSAW)], Coating Type (Clear Coat and Non-Coated), and Country

North America Welded Steel Tubes Market Scope by 2031

Download Free Sample

Source: The Insight Partners Analysis

The rise in advancements and innovations in welding techniques, such as the integration of laser welding, friction stir welding, and automated welding, helps improve the overall quality and precision of welded steel tubes. Such innovative techniques also reduce material waste during the manufacturing of welded steel tubes. Further, the demand for customized steel tubes for specific applications such as high-temperature resistance and corrosion resistance applications is increasing across various industries in North America. Also, the growing demand for corrosion-resistant welded steel tubes for harsh environment applications is supporting innovations in welding techniques. Thus, the North America welded steel tubes market trends include innovations in welding techniques.

Welded steel tubes are shaped in the form of hollow cylinders formed by welding metal strips or sheets. These tubes are made using a variety of processes, such as electric resistance welding (ERW), which involves heating the edges of a steel strip and then pressing them together to form a tube. Welded steel tubes have found various applications owing to their strength, durability, and cost-efficiency. Steel is a material with high tensile strength, making welded steel tubes ideal for structurally demanding applications. Tubes made of stainless steel or coated with galvanization are corrosion resistant, making them suitable for use in harsh environments such as chemical plants, water treatment facilities, and outdoor infrastructure.

The continuous growth in the construction, automotive, and energy sectors is contributing to the growing North America welded steel tubes market size. Urbanization, residential, commercial, and industrial infrastructure developments require high-quality steel tubes for structural and piping applications. Welded steel tubes are widely used in manufacturing processes across industries such as automotive, energy, and machinery. The expansion of manufacturing activities, particularly in the automotive industry, increases the demand for welded steel tubes. The energy sector, particularly oil and gas, requires welded steel tubes for the construction of pipelines, refineries, and power plants.

The North America welded steel tubes market analysis has been performed by considering the following segments: steel grades, type, application, and coating type. Based on steel grades, the market is segmented into carbon base grades, boron grades, alloy grades, HSLA, AHSS, and others. By type, the market is categorized into Electric Resistance Welding (ERW), Longitudinal Submerged Arc Welding (LSAW), and Spiral Submerged Arc Welded (SSAW) . On the basis of application, the market is segmented into exhaust, automotive, appliances, medical devices, HVAC, burner, conveyor belts, and others. Based on technology, the market is bifurcated into clear coat and non-coated.

COREMARK Metals; Phillips Tube Group; ArcelorMittal; Markin Tubing; Pennsylvania Steel Company, Inc.; Hofmann Industries, Inc; AMETEK Inc.; Infra-Metals Co.; Vest LLC; and RathGibsonn are among the prominent players profiled in the North America welded steel tubes market report. Various other companies are introducing new technologies and offerings to bolster the market in terms of volume as well as revenue.

The North America welded steel tubes market is segmented into the US, Canada, and Mexico. In terms of revenue, the US dominated the North America welded steel tubes market share. The demand for modern infrastructure, industrialization, and growing population are a few of the prominent factors driving the US construction industry. For example, according to the US Commerce Department in August 2023, the US construction industry is experiencing growth with a rise in construction spending. In June 2023, the construction grew by 3.5% on a year-on-year basis. The increasing demand for infrastructure projects, including the construction of bridges, buildings, roads, and public infrastructure, leads to a growing need for strong, durable materials and welded steel tubes. These tubes can be used as horizontal and vertical load-bearing structures, such as columns, beams, trusses, and supports, in high-rise buildings, large factories, bridges, TV towers, and other building structures.

According to the U.S. Energy Information Administration’s Annual Energy Outlook 2023 (AEO2023), total energy consumption in the US will rise from 0% to 15% between 2022 and 2050, owing to economic and population growth, among other factors. The energy sector, particularly the oil and gas and renewable energy industries, is a significant driver for the welded steel tubes market in the country. Pipelines, used for the transportation of oil, natural gas, and water, heavily generate the need for welded steel tubes owing to their strength, corrosion resistance, and ability to handle high pressures. The US has a significant presence of a wide number of welded steel tube market players such as UNITED STEEL INDUSTRY CO., LTD; Yieh Corp; etc.

The manufacturing sector in Canada plays a crucial role in driving the country’s economy. As per Canadian Manufacturers & Exporters (CME), in November 2023, 90,000 manufacturers contributed 9.5% of the country's real GDP. The Industrie 2030 strategy has expanded the country’s manufacturing sector. Industrie 2030 aims to create suitable conditions to support the doubling of manufacturing output in Ontario and reach US$ 600 billion by 2030. The rise in the manufacturing sector drives the demand for machines and equipment required to carry out efficient manufacturing processes. Welded steel tubes are crucial in various sectors such as construction, automotive, energy, machinery, and infrastructure, making them essential for industrial production. These tubes are used in pipes, frames, structural components, and machinery, as well as support structures in buildings.

Canada is focused on treating wastewater that can be used in different sectors, including agriculture. The government is investing in water treatment projects. For example, in February 2023, the governments of Canada and Nunavut announced a fund of US$ 1.9 million to design a phase of two new water treatment plants in Canada's Rankin Inlet and Grise Fiord. The new water treatment plants generate the demand for welded steel tubes for efficient water flow. According to the International Trade Administration (ITA), Canada’s medical device industry comprises research and development and manufacturing of medical devices. The country’s medical industry is expected to grow 5.4% annually between 2022 and 2028. Thus, the growing medical devices market drives the welded steel tubes market in Canada.

Mexico has grown into a crucial location after the implantation of the United States-Mexico-Canada Agreement (USMCA) for free trade. The nation is growing its capacity for research and development and drawing substantial investment in the automotive, aerospace, electronics, and consumer goods sectors. Due to low labor costs and open trade agreements, Mexico has become an excellent market for setting up manufacturing facilities in the country. The soaring manufacturing industry creates huge opportunities for welded steel tubes as it is used to construct frames and structural supports for various machinery and industrial equipment, such as conveyors, cranes, and material handling systems.

Mexico is planning to build many gas-fired power plants to increase the natural gas supply, including importing natural gas from the US. For instance, in November 2022, US-based New Fortress Energy announced a deal had been signed with the Mexican government to develop the LNG project Lakach offshore gas field in the country. In addition, in April 2023, the Mexican government agreed to buy 13 power plants from Iberdrola, a Spanish energy giant, in a deal worth US$ 6 billion. Thus, the rise in power plants in Mexico generates the demand for welded steel tubes to transport natural gas, which drives the market in Mexico.

Contact Us

Phone: +1-646-491-9876

Email Id: sales@theinsightpartners.com