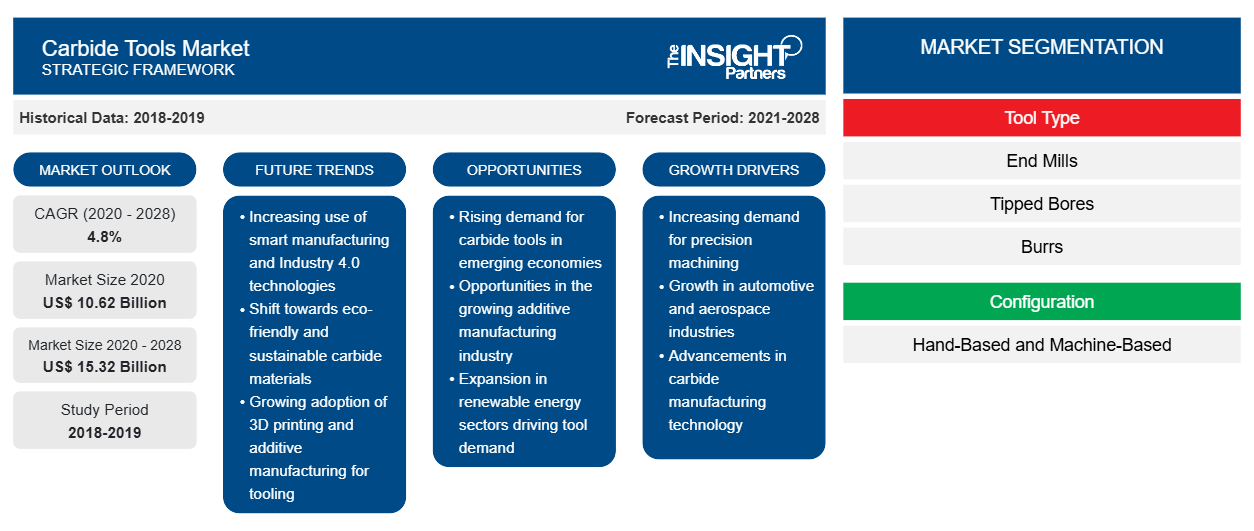

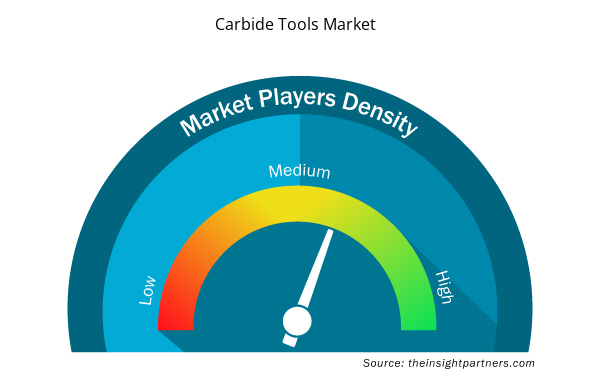

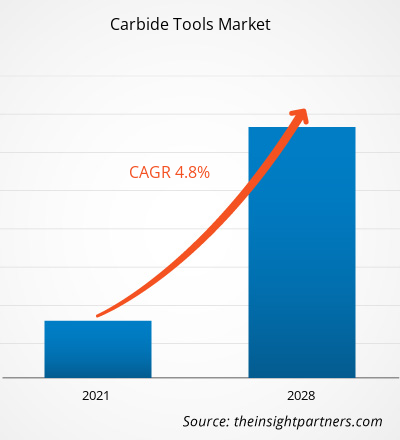

[Research Report] The carbide tools market was valued at US$ 10,623.97 million in 2020 and is projected to reach US$ 15,320.99 million by 2028; it is expected to grow at a CAGR of 4.8% from 2021 to 2028.

Rising developments in manufacturing designing and growing requirements to increase the production efficacy are establishing the base for the manufacturer’s investigation of superior machine tool products, thereby boosting the demand for carbide tools. The machine tools used across industries are primarily utilized for machining or shaping metal or other rigid materials to offer a unique form with the help of boring, grinding, shearing, and cutting. Presently, there are two main types of machine tools significantly being used across different industries – high-speed steel (HSS) and carbide tools. These tools are extensively used across machining applications due to their significant features such as high speed, reduced cycle time, long working life, retaining cutting edge at high machining temperature, and exceptional wear resistance at cutting edge. The rising popularity of carbide tools, particularly across manufacturing applications, is one of the significant factors expected to boost the market during the forecast period. Furthermore, these carbide tools are being used in manufacturing units across automotive, aerospace, railway, furniture & carpentry, energy & power, and healthcare equipment industries. In these industries, special cutting tools are used to design and manufacture a product, which is propelling the demand for carbide tools. The deployment of carbide tools across different industries to operate it manually or automatically is further boosting the growth of the carbide tools market globally.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Carbide Tools Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Carbide Tools Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Impact of COVID-19 Pandemic on Carbide Tools Market

The COVID-19 pandemic has shaken several industries. The tremendous growth in the spread of the virus has urged governments worldwide to impose strict restrictions on vehicles’ and human’s movement. Due to travel bans, mass lockdowns, and business shutdowns, the pandemic has adversely affected economies and countless industries in various countries. The lockdown imposition has resulted in lesser production of commodities, goods, and services. Therefore, manufacturing, automotive, semiconductor & electronics, oil & gas, mining, aviation, and other industries have witnessed a decline in their operations due to the temporary shutdown of activities.

The worldwide lockdown to minimize the transmission of virus has significantly disrupted the supply chain activities along with production volume across several manufacturers, especially the small & medium enterprise owners. Moreover, the production activities in multiple industries have contracted significantly during 2020, resulting in decline in the carbide tools market. However, with the increasing need for healthcare products, the demand for carbide tools is surging from the medical industries.

Carbide Tools Market Insights

Increased Production in Automotive Sector Fuels Growth of Carbide Tools Market

Automotive production is constantly rising across the world, particularly in Asian and European countries, which is driving the demand for carbide tools. The sector widely uses carbide tools in crankshaft metal machining, face milling, and hole-making, among other machining operations involved in auto parts manufacturing. The automotive industry is obtaining excellent results with the use of tungsten carbide in ball joints, brakes, crank shafts in performance vehicles, and other mechanical parts of a vehicle that sees hard usage and extreme temperatures. Automotive giants such as Audi, BMW, Ford Motor Company, and Range Rover are contributing significantly to the carbide tools market growth. Hybrid electric vehicles are gaining traction in North America, thus boosting the carbide tools market growth in the region. Countries such as the US and Canada are prominent automotive manufacturers in the region. According to the American Automotive Policy Council, automakers and their suppliers contribute ~3% to the US GDP. General Motors Company, Ford Motor Company, Fiat Chrysler Automobiles, and Daimler are among the major automotive manufacturers in North America. As per data by the International Organization of Motor Vehicle Manufacturers, in 2019, the US and Canada manufactured ~2,512,780 and ~461,370 cars, respectively. Further, the carbide tools are also highly used in railway, aerospace & defense, and marine industries.

Tool Type - Based Market Insights

Based on tool type, the carbide tools market is segmented into end mills, tipped bores, burrs, drills, cutters, and other tools. In 2020, the end mills segment accounted for the largest share in the market.

Configuration-Based Market Insights

Based on configuration, the carbide tools market is bifurcated into hand-based and machine-based. In 2020, the machine-based segment accounted for a larger market share.

End-User-Based Market Insights

By end-user, the carbide tools market is segmented into automotive and transportation, metal fabrication, construction, oil and gas, heavy machinery, and other end-users. In 2020, the automotive and transportation segment accounted for the largest share in the market.

The players operating in the carbide tools market adopt strategies such as mergers, acquisitions, and market initiatives to maintain their positions in the market. A few developments by key players are listed below:

- In November 2020, GARR TOOL entered a partnership with Mastercam to offer complete tool library to customers natively inside the Mastercam platform. The partnership will be of tremendous value for current and future customers as the manufacturing process becomes more and more reliant on instant and easy access to data.

- In February 2019, CERATIZIT Group acquired 50% of the shares in Stadler Metalle GmbH & Co. KG. The company stated that the investment in Stadler enabled them to secure the entire raw materials supply chain and focus even more strongly on recycling carbide tools in the supply of raw materials.

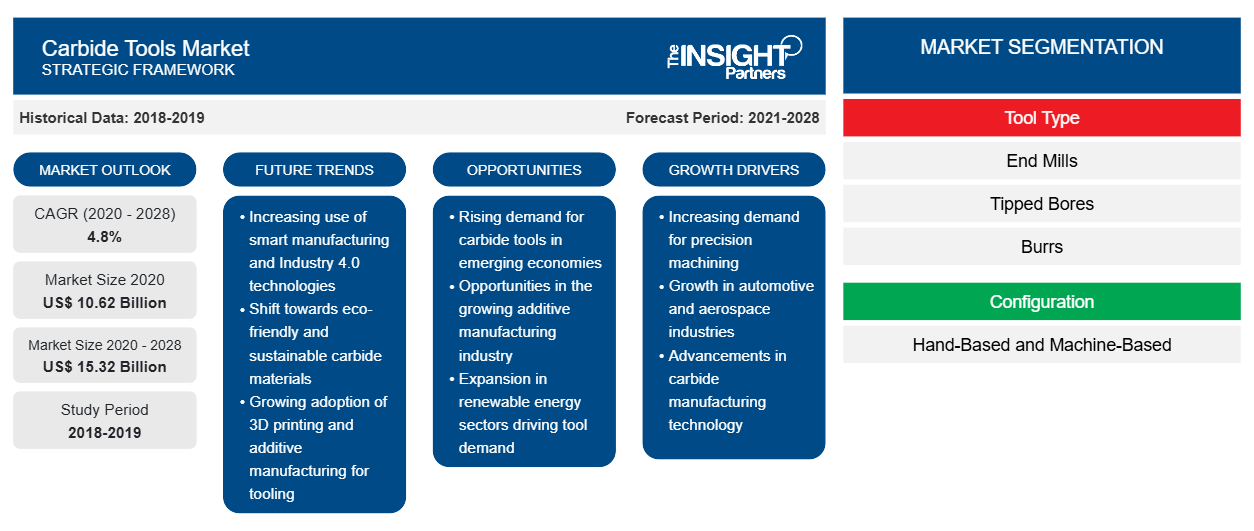

Carbide Tools Market Regional Insights

The regional trends and factors influencing the Carbide Tools Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Carbide Tools Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Carbide Tools Market

Carbide Tools Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2020 | US$ 10.62 Billion |

| Market Size by 2028 | US$ 15.32 Billion |

| Global CAGR (2020 - 2028) | 4.8% |

| Historical Data | 2018-2019 |

| Forecast period | 2021-2028 |

| Segments Covered |

By Tool Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

Carbide Tools Market Players Density: Understanding Its Impact on Business Dynamics

The Carbide Tools Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Carbide Tools Market are:

- Mitsubishi Materials Corporation

- Sandvik Coromant

- KYOCERA Precision Tools

- Ingersoll Cutting Tool Company

- CERATIZIT S.A.

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Carbide Tools Market top key players overview

The global carbide tools market has been segmented as mentioned below:

By Tool Type

- End Mills

- Tipped Bores

- Burrs

- Drills

- Cutters

- Other Tools

By Configuration

By End-User

- Automotive and Transportation

- Metal Fabrication

- Construction

- Oil and Gas

- Heavy Machinery

- Other End-users

By Geography

- North America

- US

- Canada

- Mexico

- Europe

- France

- Germany

- Italy

- UK

- Russia

- Rest of Europe

- Asia Pacific (APAC)

- China

- India

- South Korea

- Japan

- Australia

- Rest of APAC

- Middle East & Africa (MEA)

- South Africa

- Saudi Arabia

- UAE

- Rest of MEA

- South America (SAM)

- Brazil

- Argentina

- Rest of SAM

Company Profiles

- Xinrui Industry Co., Ltd.

- CERATIZIT S.A.

- GARR TOOL

- Ingersoll Cutting Tool Company

- KYOCERA Precision Tools

- DIMAR GROUP

- MITSUBISHI MATERIALS Corporation

- Sandvik Coromant

- YG-1 Co., Ltd.

- Makita Corporation

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Tool Type , Configuration , and End-User

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

Argentina, Australia, Brazil, Canada, China, France, Germany, India, Italy, Japan, Mexico, Russian Federation, Saudi Arabia, South Africa, South Korea, United Arab Emirates, United Kingdom, United States

Frequently Asked Questions

The carbide tools market is led by end mills segment with highest share and is expected to dominate in the forecast period. The carbide end mills are heat resistant and are used in high-speed applications to cut the hardest materials, such as cast iron, alloys, plastics, and non-ferrous metals. End mills cut rotationally in a horizontal and lateral (side to side) direction. Moreover, carbide end mills are used to cut machine parts, wood engravings, jewelry designs, and plastic cutting, among others. The end mills usually perform operations including profiling, slotting, contouring, reaming, and counter boring.

The carbide cutting tools form an essential part of industrial tools. These tools are used in metal cutting tools for several materials on heavy duty machines such as CNC (computer numerical control) lathes, engines lathes, and turret lathes. Carbide cutting tools are extensively used in machining applications owing to their features such as high-speed operations; high temperature withstanding ability, allowing the retention of the cutting edge; exceptional wear resistance, especially at the cutting edge; and ability to reduce cycle time along with ensuring prolonged working life is anticipated to offer ample growth opportunities for the global carbide tools market players.

Automotive production is constantly rising across the world, particularly in Asian and European countries, which is driving the demand for carbide tools. The sector widely uses carbide tools in crankshaft metal machining, face milling, and hole-making, among other machining operations involved in auto parts manufacturing. The automotive industry is obtaining excellent results with the use of tungsten carbide in ball joints, brakes, crank shafts in performance vehicles, and other mechanical parts of a vehicle that sees hard usage and extreme temperatures. Automotive giants such as Audi, BMW, Ford Motor Company, and Range Rover are contributing significantly to the carbide tools market growth.

Trends and growth analysis reports related to Manufacturing and Construction : READ MORE..

The List of Companies - Carbide Tools Market

- Mitsubishi Materials Corporation

- Sandvik Coromant

- KYOCERA Precision Tools

- Ingersoll Cutting Tool Company

- CERATIZIT S.A.

- Xinrui Industry Co., Ltd.

- GARR TOOL

- DIMAR GROUP

- YG-1 Co., Ltd.

- Makita Corporation

Get Free Sample For

Get Free Sample For