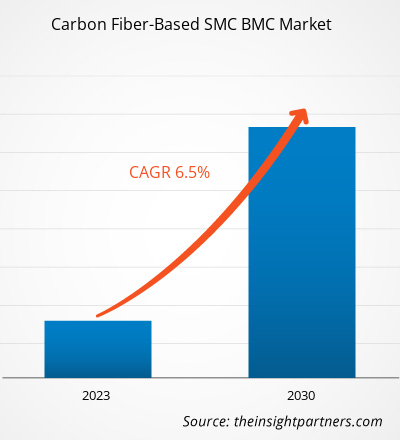

[Research Report] The carbon fiber-based SMC BMC market size was valued at US$ 749.51 million in 2022 and is projected to reach US$ 1,240.08 million by 2030; it is anticipated to record a CAGR of 6.5% from 2022 to 2030.

MARKET ANALYSIS

Carbon fiber-based BMC consists of short carbon fibers, fillers, and resin systems formed into bulk material. It is utilized in applications where high performance and dimensional precision are required. Replacing metal components with lightweight carbon fiber-based BMC and SMC reduces vehicle weight and offers an additional advantage of chemical and fire resistance. Furthermore, rising sustainability initiatives across the world and stringent government regulations prompt manufacturers to recycle SMC and BMC. Recycling of carbon fiber-based SMC and BMC is achieved through mechanical shredding and grinding.

GROWTH DRIVERS AND CHALLENGES

The growing automotive industry and increasing demand for lightweight and durable materials drive the carbon fiber-based SMC BMC market growth. Carbon fiber-based SMC and BMC are lightweight and offer durability, design flexibility, tolerance to temperature fluctuations, and chemical resistance. They have various applications such as automotive body panels, structural components, and insulating components. The demand for SMC and BMC for the production of automobiles has increased due to a high emphasis on reducing vehicle weight and enhancing fuel efficiency. The rise in electric and hybrid vehicles has further boosted the demand for lightweight materials for the insulation of electrical components. Thus, the growing automotive industry propels the demand for automotive components, subsequently boosting the carbon fiber-based SMC BMC market growth. Availability of substitute products for carbon fiber-based SMC BMC poses a challenge to the carbon fiber-based SMC BMC market. Glass fiber-based SMC and BMC, aluminum alloys, thermoplastics, natural fiber composites, thermoplastic composites, and metal matrix composites are among the substitutes of carbon fiber-based SMC and BMC. Glass fiber-based SMC and BMC have characteristics like carbon fiber-based SMC and BMC. However, they are cost-effective solutions. Aluminum alloys are used in the automotive and aerospace industries due to their high strength and corrosion resistance. Thus, the availability of substitutes restrains the carbon fiber-based SMC BMC market growth.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

REPORT SEGMENTATION AND SCOPE

The "Global Carbon Fiber-Based SMC BMC Market Analysis to 2030" is a specialized and in-depth study with a significant focus on global market trends and growth opportunities. The report aims to provide an overview of the global market with detailed market segmentation on the basis of resin type, end-use industry, and geography. The report provides key statistics on the consumption of carbon fiber-based SMC BMC across the world, along with their demand in major regions and countries. In addition, the report provides a qualitative assessment of various factors affecting the carbon fiber-based SMC BMC market performance in major regions and countries. It also includes a comprehensive analysis of the leading players in the carbon fiber-based SMC BMC market and their key strategic developments. Analysis of the market dynamics is also included to help identify the key driving factors, market trends, and lucrative opportunities that would, in turn, aid in identifying the major revenue pockets.

The ecosystem analysis and Porter’s five forces analysis provide a 360-degree view of the global carbon fiber-based SMC BMC market, which helps understand the entire supply chain and various factors affecting the market growth.

SEGMENTAL ANALYSIS

The global carbon fiber-based SMC BMC market is segmented on the basis of resin type and end-use industry. Based on resin type, the carbon fiber-based SMC BMC market is segmented into polyester, vinyl ester, epoxy, and others. Based on end-use industry, the market is segmented into automotive, aerospace, electrical and electronics, building and construction, and others. Based on resin type, the polyester segment accounted for a significant share of the carbon fiber-based SMC BMC market in 2022. Processing advantages of polyester such as low viscosity, fast cure, and improved processing robustness help reduce cycle times significantly and eventually lead to increased productivity. Vinyl ester resins are considered a popular resin type used in BMC and SMC production. Vinyl ester resins possess several characteristic features such as low viscosity, mechanical properties, low processing cost, and the ability to cure at room temperature. Polyetherketoneketone (PEKK), Polyether ether ketone (PEEK), Polyphenylene Sulfide (PPS), and Polyetherimide (PEI) are among the other resin types used for the production of carbon fiber-based SMC BMC products. Based on end-use industry, the automotive segment accounted for a significant share in 2022. The automotive industry has emphasized the production of lightweight components, thereby replacing metals and alloy materials. BMC formulation withstands high temperatures and adverse environmental conditions, making it an ideal choice for engine components such as ignition systems and sensors in the aerospace industry. SMC and BMC are generally used to manufacture electrical enclosures and cabinets. These materials are also designed to have properties such as moisture resistance and corrosion resistance and meet safety standards for electrical equipment. SMC and BMC offer high strength, durability, and tolerance to adverse environmental conditions. Façade elements, including decorative trims, cornices, architectural elements, and others, are produced from SMC and BMC as they offer weathering resistance and design flexibility.

REGIONAL ANALYSIS

The report provides a detailed overview of the global carbon fiber-based SMC BMC market with respect to five major regions—North America, Europe, Asia-Pacific (APAC), the Middle East & Africa (MEA), and South & Central America. Asia Pacific accounted for a significant share of the global carbon fiber-based SMC BMC market and was valued at more than US$ 350 million in 2022. Asia Pacific is a hub for automotive manufacturing with a large presence of international and domestic players operating in the region. The International Organization of Motor Vehicle Manufacturers report stated that various countries in Asia Pacific produced ~46.73 million units of motor vehicles in 2021. In the production of cars, trucks, buses, and agricultural vehicles, SMC and BMC products offer advantages such as parts consolidation, corrosion resistance, low weight, and others. Benefits of SMC and BMC products, coupled with the growing automotive industry, propel the market growth in Asia Pacific. The Europe carbon fiber-based SMC BMC market is expected to reach more than US$ 250 million by 2030. The automotive industry is a major industry in Europe as it contributes significantly to the GDP of many European countries, including Germany, the UK, and Italy. According to the report by the European Commission, in 2021, turnover generated by the industry in Europe represents 7% of the region’s total GDP. The North America carbon fiber-based SMC BMC market is expected to record a CAGR of ~6% from 2022 to 2030. North America offers an extensive growth opportunity for the players of carbon fiber-based SMC BMC due to the growing end-use industries, such as automotive, aerospace, and electrical & electronics industries.

INDUSTRY DEVELOPMENTS AND FUTURE OPPORTUNITIES

Various initiatives taken by the key players operating in the carbon fiber-based SMC BMC market are listed below:

- In 2023, Engenuity developed a new approach to SMC, Failure in Random Material Architectures (FiRMA). This uses a predictive technique that accurately reflects material properties and determines the performance range an SMC part or structure will exhibit.

- In 2021, AOC, Zoltek, and Astar developed novel CF-SMC for high-performance automotive parts on an industrial scale. AOC AG (Schaffhausen, Switzerland), with Astar (Biscay, Spain), has developed a new sheet molding compound based on Daron polyurethane hybrid technology under the UK government-funded research project, TUCANA.

Carbon Fiber-Based SMC BMC Market Regional Insights

The regional trends and factors influencing the Carbon Fiber-Based SMC BMC Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Carbon Fiber-Based SMC BMC Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Carbon Fiber-Based SMC BMC Market

Carbon Fiber-Based SMC BMC Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2022 | US$ 749.51 Million |

| Market Size by 2030 | US$ 1,240.08 Million |

| Global CAGR (2022 - 2030) | 6.5% |

| Historical Data | 2020-2021 |

| Forecast period | 2023-2030 |

| Segments Covered |

By Resin Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

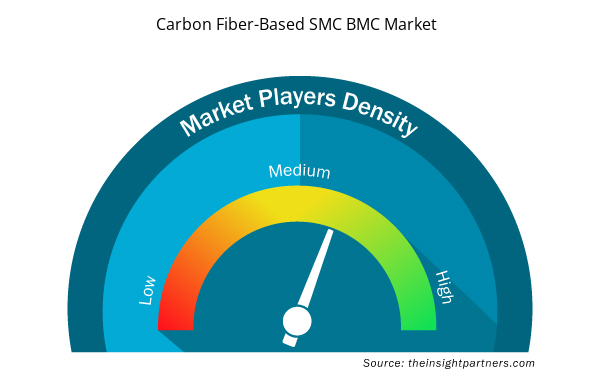

Carbon Fiber-Based SMC BMC Market Players Density: Understanding Its Impact on Business Dynamics

The Carbon Fiber-Based SMC BMC Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Carbon Fiber-Based SMC BMC Market are:

- Teijin Carbon Europe GmBH

- Mitsubishi Chemical Corp

- ASTAR SA

- Menzolit

- Polynt SpA

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Carbon Fiber-Based SMC BMC Market top key players overview

IMPACT OF COVID-19 PANDEMIC/IMPACT OF GEOPOLITICAL SCENARIO/IMPACT OF RECESSION

Industries such as automotive, electronics, and aerospace have been the major consumers of carbon fiber-based SMC BMC. In 2020, these industries had to slow down their operations due to disruptions in the value chain caused by government regulations and trade restrictions. Moreover, lockdowns imposed by different countries hampered the inventory levels of many manufacturers in the same year. The shortage of labor resulted in a reduction in carbon fiber-based SMC BMC production and distribution operations. Additionally, government restrictions and other COVID-19-related precautions reduced the operational capacities of stakeholders in the carbon fiber-based SMC BMC market value chain.

In late 2021, the global carbon fiber-based SMC BMC market began recovering from the losses incurred in 2020, with the revival of end-use industries such as automotive, construction, and electrical & electronics. Expansion in production capacities in the chemicals & materials industry post-COVID-19 pandemic in many regions, such as Asia Pacific and North America, is expected to create lucrative opportunities for the carbon fiber-based SMC BMC market in the coming years.

COMPETITIVE LANDSCAPE AND KEY COMPANIES

Teijin Carbon Europe GmBH, Mitsubishi Chemical Corp, ASTAR SA, Menzolit, Polynt SpA, IDI Composite International, LyondellBasell Industries Holdings BV, Lattice Composites LLC, Toray Advanced Composites, and YS ACC are among the key players operating in the carbon fiber-based SMC BMC market.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Resin Type, and End-Use Industry

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

This text is related

to country scope.

Frequently Asked Questions

In 2022, Asia Pacific held the largest share of the global carbon fiber-based SMC BMC market. The Asia Pacific carbon fiber-based SMC and BMC market is segmented into China, Japan, India, Australia, South Korea, and the Rest of Asia Pacific. The market growth in Asia Pacific is driven by the strong presence of the automotive, building & construction, electronics, wind energy, and other industries. Asia Pacific is a hub for automotive manufacturing with a large presence of international and domestic players operating in the region.

The projected growth of the market is attributed to the growing global automotive industry, rising construction activities, and the increasing demand for lightweight, durable, and fire-resistant materials.

The key players operating in the global carbon fiber-based SMC BMC market include Teijin Carbon Europe GmBH, Mitsubishi Chemical Corp, ASTAR SA, Menzolit, Polynt SpA, IDI Composite International, LyondellBasell Industries Holdings BV, Lattice Composites LLC, Toray Advanced Composites, and YS ACC, among others.

The polyester segment held the largest share in the global carbon fiber-based SMC BMC market in 2022. Polyester is a synthetic polymer usually derived from petroleum. It is a versatile material known for its strength, durability, and resistance to several environmental factors.

The automotive segment held the largest share of the global carbon fiber-based SMC BMC market in 2022. SMC and BMC are used for the fabrication of car components such as body panels, hoods, tailgates, headlamp reflectors, spoilers, valve covers, and battery support.

The building and construction segment is estimated to register the fastest CAGR in the global carbon fiber-based SMC BMC market over the forecast period. SMC and BMC are used to manufacture building panels for walls, roofs, and facades. The panels are lightweight and durable and offer design flexibility, making them ideal for residential and commercial applications.

Trends and growth analysis reports related to Chemicals and Materials : READ MORE..

The List of Companies - Carbon Fiber-Based SMC BMC Market

- Teijin Carbon Europe GmBH

- Mitsubishi Chemical Corp

- ASTAR SA

- Menzolit

- Polynt SpA

- IDI Composite International

- LyondellBasell Industries Holdings BV

- Lattice Composites LLC

- Toray Advanced Composites

- YS ACC

Get Free Sample For

Get Free Sample For