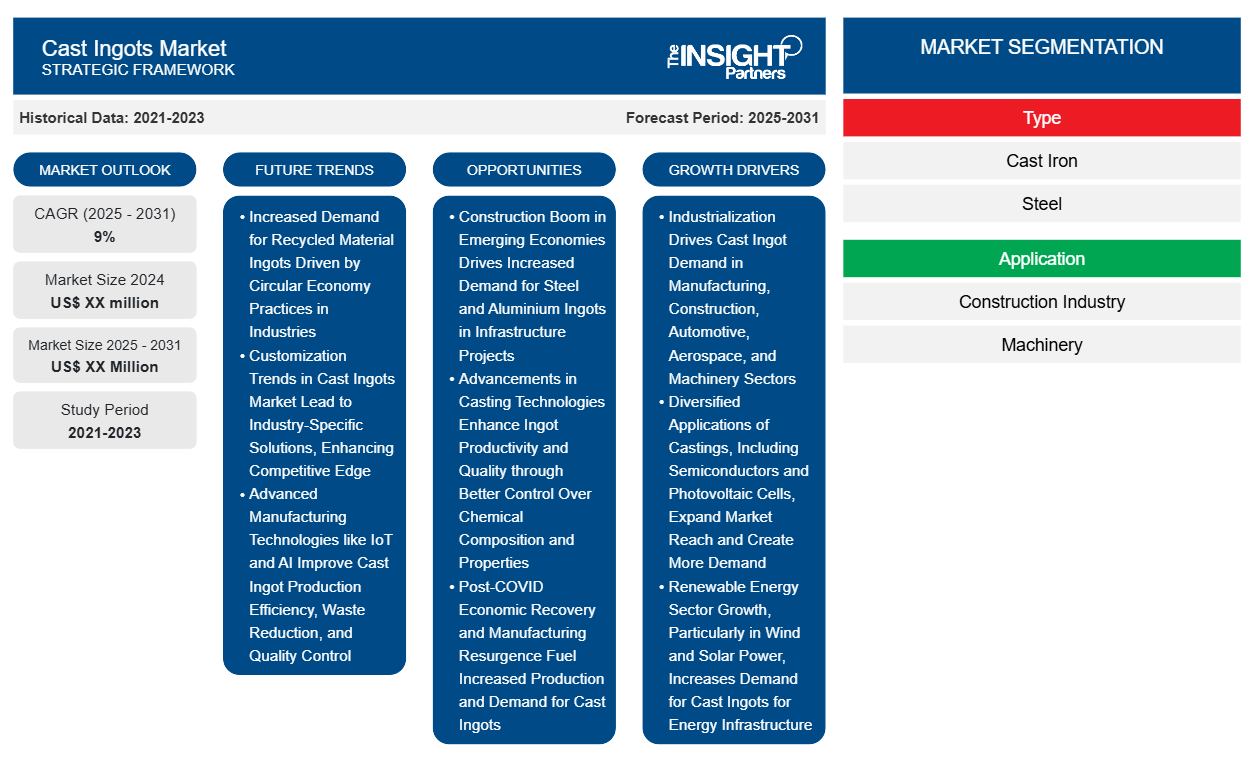

The Cast Ingots Market is expected to register a CAGR of 9% from 2025 to 2031, with a market size expanding from US$ XX million in 2024 to US$ XX Million by 2031.

Cast Ingots Market covers analysis By Type (Cast Iron, Steel, Others); Application (Construction Industry, Machinery, Others), and Geography (North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America). An ingot is a form that can have various dimensions. Cast ingots are available in different sizes, forms, and materials. Depending on material and size, it plays an important role in various industries. Ingots produced by casting are especially used within the heavy industry, the shipbuilding sector, and in heavy-duty cranes. They are also used in the construction industry and in the manufacturing of tools and construction machinery.

Purpose of the Report

The report Cast Ingots Market by The Insight Partners aims to describe the present landscape and future growth, top driving factors, challenges, and opportunities. This will provide insights to various business stakeholders, such as:

- Technology Providers/Manufacturers: To understand the evolving market dynamics and know the potential growth opportunities, enabling them to make informed strategic decisions.

- Investors: To conduct a comprehensive trend analysis regarding the market growth rate, market financial projections, and opportunities that exist across the value chain.

- Regulatory bodies: To regulate policies and police activities in the market with the aim of minimizing abuse, preserving investor trust and confidence, and upholding the integrity and stability of the market.

Cast Ingots Market Segmentation

Type

- Cast Iron

- Steel

Application

- Construction Industry

- Machinery

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Cast Ingots Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Cast Ingots Market Growth Drivers

- Industrialization Drives Cast Ingot Demand in Manufacturing, Construction, Automotive, Aerospace, and Machinery Sectors: The increasing industrialization mainly in manufacturing and construction industries highly drives demand for cast ingots. Industries like automotive, aerospace, and machinery are highly dependent on cast ingots since castings become the raw material majorly used in all these companies' components.

- Diversified Applications of Castings, Including Semiconductors and Photovoltaic Cells, Expand Market Reach and Create More Demand: Castings are utilized in various applications beyond the commercial scope. Applications of silicon castings encompass manufacturing semiconductors and producing photovoltaic cells. Such diversification increases their markets and creates more demand for different types of castings.

- Renewable Energy Sector Growth, Particularly in Wind and Solar Power, Increases Demand for Cast Ingots for Energy Infrastructure: Renewable sources of energy, particularly wind and sun power, promise to represent a massive demand for cast ingots as such might be used in the creation of energy infrastructure. Often, parts for both wind turbines and solar panels require high-performance materials like those that a cast ingot can provide.

Cast Ingots Market Future Trends

- Increased Demand for Recycled Material Ingots Driven by Circular Economy Practices in Industries: This has, to a large extent, led to an increase in casting demand for recycled material ingots. Most industries adopt the circular economy practice-that is, recycle metals and cast them into new ingots.

- Customization Trends in Cast Ingots Market Lead to Industry-Specific Solutions, Enhancing Competitive Edge: The trend in customization in the cast ingots market is also on an increase. The manufacturers would likely provide their solution to meet specific industry requirements such as particular alloy composition or special size requirement. This would, therefore help companies differentiate themselves while serving niche markets, thereby furthering their competitive strength.

- Advanced Manufacturing Technologies like IoT and AI Improve Cast Ingot Production Efficiency, Waste Reduction, and Quality Control: Such advanced manufacturing practices as IoT and AI in cast ingot production will change it completely. These technologies may help in the reduction of waste and better efficiency while increasing quality control.

Cast Ingots Market Opportunities

- Construction Boom in Emerging Economies Drives Increased Demand for Steel and Aluminium Ingots in Infrastructure Projects: Another major driver is the construction boom in the emerging economies. This is because, with increased urbanization and extended infrastructure projects, there is a growing demand for steel and aluminium ingots. Cast ingots are indispensable in constructing structures, bridges, and other infrastructure.

- Advancements in Casting Technologies Enhance Ingot Productivity and Quality through Better Control Over Chemical Composition and Properties: New casting technologies have been advancing ingot productivity efficiency and also the quality of products. In this sense, new melting and casting procedures permit better control over both the chemical composition and intrinsic properties of the ingots.

- Post-COVID Economic Recovery and Manufacturing Resurgence Fuel Increased Production and Demand for Cast Ingots: In the aftermath of such interruptions as the COVID-19 pandemic in the World economy, an increase in manufacturing can be seen. The production volumes are increasing in all sectors with this recovery. High production rates correspondingly create demand for cast ingots.

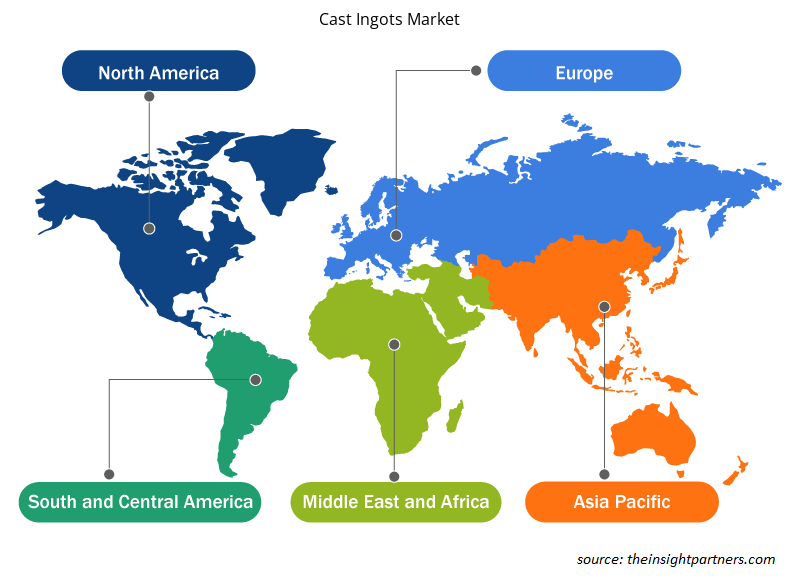

Cast Ingots Market Regional Insights

The regional trends and factors influencing the Cast Ingots Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Cast Ingots Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Cast Ingots Market

Cast Ingots Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ XX million |

| Market Size by 2031 | US$ XX Million |

| Global CAGR (2025 - 2031) | 9% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

Cast Ingots Market Players Density: Understanding Its Impact on Business Dynamics

The Cast Ingots Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Cast Ingots Market are:

- Silbitz Group

- Paras Steel Industries

- Norsk Hydro ASA

- Sharu Steels Private Limited

- Alcoa

- Manaksia

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Cast Ingots Market top key players overview

Key Selling Points

- Comprehensive Coverage: The report comprehensively covers the analysis of products, services, types, and end users of the Cast Ingots Market, providing a holistic landscape.

- Expert Analysis: The report is compiled based on the in-depth understanding of industry experts and analysts.

- Up-to-date Information: The report assures business relevance due to its coverage of recent information and data trends.

- Customization Options: This report can be customized to cater to specific client requirements and suit the business strategies aptly.

The research report on the Cast Ingots Market can, therefore, help spearhead the trail of decoding and understanding the industry scenario and growth prospects. Although there can be a few valid concerns, the overall benefits of this report tend to outweigh the disadvantages.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

This text is related

to segments covered.

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

This text is related

to country scope.

Frequently Asked Questions

The growing technological advancements is an emerging trend in the market.

The poches packaging format segment accounted for the largest market share in 2023.

Based on geography, Asia Pacific held the largest share of the cast ingots market due to the growing manufacturing industry in the region.

The growing manufacturing and construction industry globally is a key driver in the market.

Silbitz Group, Paras Steel Industries, Norsk Hydro ASA, Sharu Steels Private Limited, Alcoa, Manaksia, Shubh Castings, Bharat Engineering Works, Shin Wen Ching Emtal Enterprise., Ltd, and MORIMURA BROS.,INC are some of the key players operating in the market.

The Cast Ingots Market is estimated to witness a CAGR of 9% from 2023 to 2031

Trends and growth analysis reports related to Chemicals and Materials : READ MORE..

1. Silbitz Group

2. Paras Steel Industries.

3. Norsk Hydro ASA

4. Sharu Steels Private Limited.

5. Alcoa

6. Manaksia

7. Shubh Castings

8. Bharat Engineering Works

9. Shin Wen Ching Emtal Enterprise., Ltd.

10. MORIMURA BROS.,INC.

Get Free Sample For

Get Free Sample For