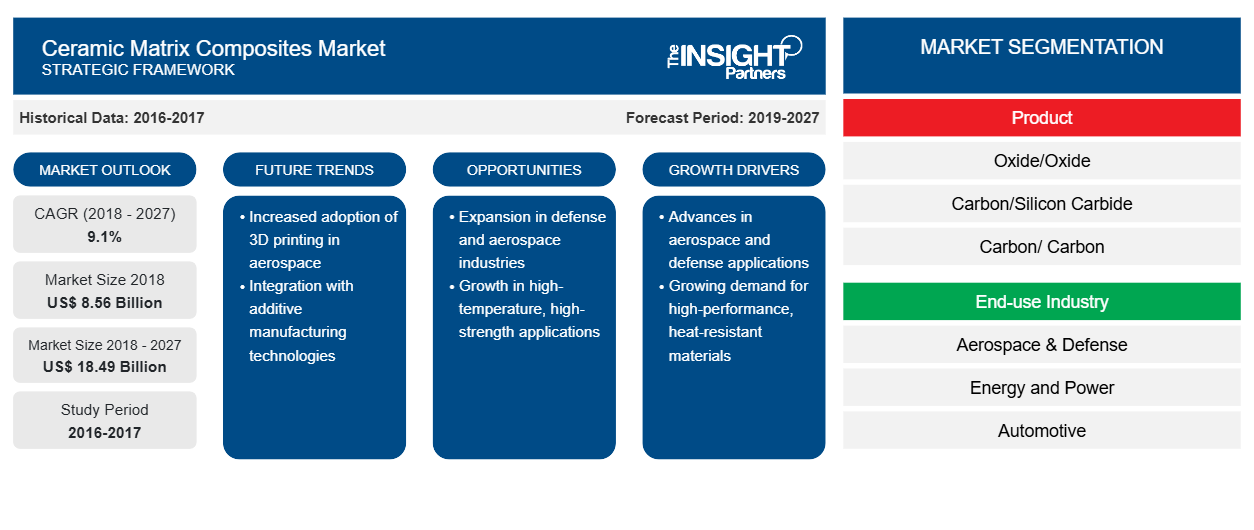

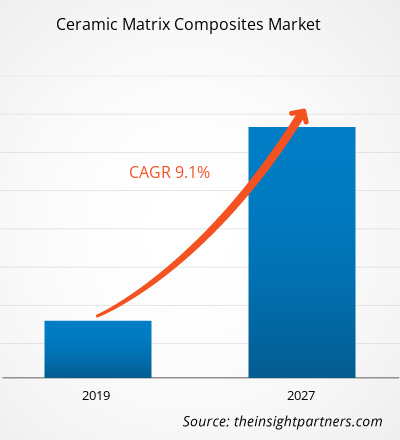

[Research Report] The ceramic matrix composites market accounted to US$ 8,560.0 Mn in 2018 and is expected to grow at a CAGR of 9.1% during the forecast period 2019 - 2027, to account to US$ 18,485.0 Mn by 2027.

MARKET ANALYSIS

Ceramic matrix composites (CMCs) refer to a class of advanced materials that combine ceramic fibers or particles with a ceramic matrix to create a high-performance composite material. These composites are designed to leverage the desirable properties of both the reinforcing fibers/particles and the ceramic matrix to achieve improved mechanical strength, thermal stability, and other enhanced characteristics compared to traditional ceramic materials. The mechanical properties of the ceramic matrix composites such as high heat resistance and tensile strength make it an important part of the automotive, defense and aerospace sectors. The rise in application base in various end-use industries is expected to provide the opportunity for the growth of the ceramic matrix composites market.

GROWTH DRIVERS AND CHALLENGES

The increasing demand for ceramic matrix composites (CMCs) in emerging industries stems from their unique properties that align with the requirements of these sectors. In renewable energy, CMCs find applications in wind turbines and solar power systems, where their lightweight nature helps improve energy efficiency and reduce costs. Additionally, the high-temperature performance of CMCs makes them suitable for use in concentrated solar power plants and geothermal energy systems. In the electric vehicle industry, CMCs offer lightweight and high-strength solutions for components like battery casings, motor housings, and brake systems, contributing to the development of more efficient and sustainable electric vehicles. The versatility of CMCs positions them as a promising material choice in these emerging industries, driving ceramic matrix composites market growth.

However, high cost of ceramic matrix composites (CMCs) acts as a significant restraint on ceramic matrix composites market growth. The complex and specialized manufacturing processes involved in producing CMCs, including fiber production, matrix preparation, and composite fabrication, contribute to higher production costs compared to traditional materials. This cost premium limits the widespread adoption of CMCs, particularly in industries that prioritize cost-effectiveness. The high cost also poses challenges for smaller manufacturers or companies with limited resources, as they may find it difficult to invest in the necessary equipment and expertise for CMC production. Moreover, the limited scalability of CMC production processes further restricts their availability in large quantities, making them less accessible and affordable for potential users. As a result, the high cost of CMCs acts as a barrier for the ceramic matrix composites market growth.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Ceramic Matrix Composites Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Ceramic Matrix Composites Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

REPORT SEGMENTATION AND SCOPE

The "Global Ceramic Matrix Composites Market Analysis to 2027" is a specialized and in-depth study with a major focus on the global ceramic matrix composites market trends and growth opportunities. The report aims to provide an overview of the global ceramic matrix composites market with detailed market segmentation by product, end-use industry, and geography. The global ceramic matrix composites market has been witnessing high growth over the recent past and is expected to continue this trend during the forecast period. The report provides key statistics on the consumption of ceramic matrix composites worldwide along with their demand in major regions and countries. In addition, the report provides the qualitative assessment of various factors affecting the ceramic matrix composites market performance in major regions and countries. The report also includes a comprehensive analysis of the leading players in the ceramic matrix composites market and their key strategic developments. Several analyses on the market dynamics are also included to help identify the key driving factors, market trends, and lucrative ceramic matrix composites market opportunities that would, in turn, aid in identifying the major revenue pockets.

Further, ecosystem analysis and Porter’s five forces analysis provide a 360-degree view of the global ceramic matrix composites market, which helps understand the entire supply chain and various factors affecting the market growth.

SEGMENTAL ANALYSIS

The global ceramic matrix composites market is segmented based on product and end-use industry. Based on product, the ceramic matrix composites market is segmented as oxides/oxide, silicon carbide/ silicon carbide, carbon/silicon carbide, and carbon/ carbon. Based on end-use industry, the ceramic matrix composites market is classified as, aerospace & defense, energy & power, automotive, industrial, and others.

Based on product, the oxides/oxide segment accounted for a significant ceramic matrix composites market share in 2022. Oxides/oxide ceramic matrix composites (CMCs) are playing a significant role in driving the growth of the market. These CMCs offer unique advantages such as excellent thermal stability, high-temperature resistance, and improved mechanical properties. Oxides, such as aluminum oxide (Al2O3) and zirconium oxide (ZrO2), serve as the ceramic matrix in these composites, while oxide-based fibers, such as alumina fibers, reinforce the structure. The oxide/oxide CMCs find extensive applications in industries such as aerospace, defense, and energy, where their exceptional thermal properties and durability are crucial. They are used in hot sections of gas turbine engines, thermal barrier coatings, and high-temperature components in aircraft and space exploration. The growing demand for high-performance materials capable of withstanding extreme temperatures and harsh environments is driving the adoption of oxide/oxide CMCs, leading to ceramic matrix composites market expansion and growth opportunities.

REGIONAL ANALYSIS

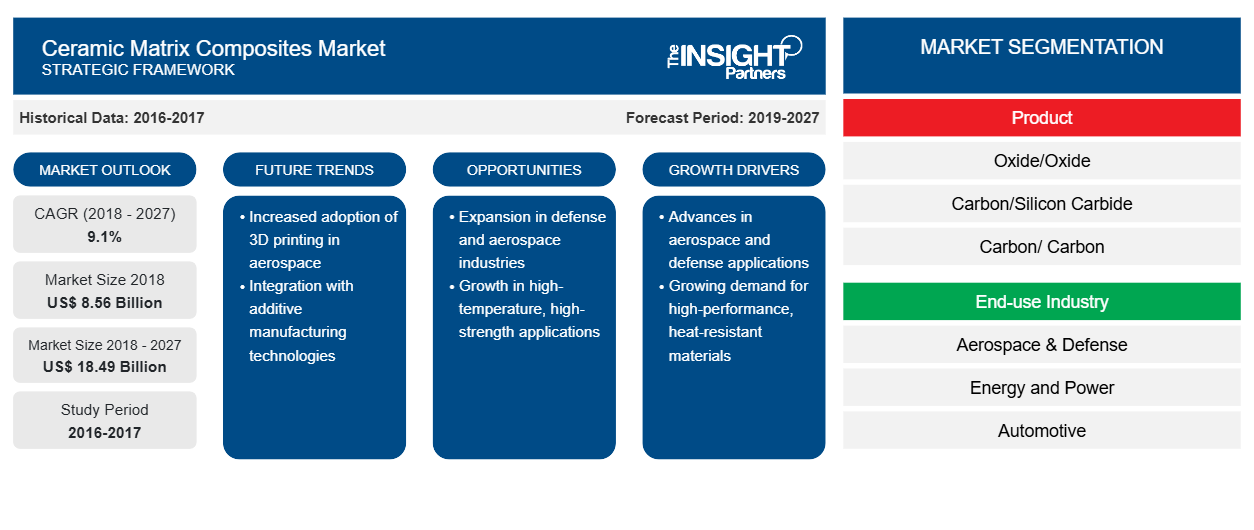

The report provides a detailed overview of the global ceramic matrix composites market with respect to five major regions, namely; North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South & Central America. North America region dominated the ceramic matrix composites market, having revenue more than US$ 4500 million in 2022. North America has a strong presence of key industries that extensively utilize CMCs, such as aerospace, defense, and energy. These industries have a high demand for advanced materials with superior properties, including lightweight, high strength, and thermal stability, which CMCs can provide. The Europe ceramic matrix composites market is expected to reach revenue of more than US$ 7300 million in 2028. The CMC industry has gained a significant place in the European economy, fostering growth, innovation, and employment. CMC is closely related to various industrial sectors such as defense, aerospace, energy and power electrical and electronics industries. The ceramic matrix composites market in Asia Pacific is expected to grow at significant CAGR of more then 10%. The countries across the region are witnessing an upsurge in the population as well as growth in urbanization, which provides ample opportunities for the key market players in the CMC market.

INDUSTRY DEVELOPMENTS AND FUTURE OPPORTUNITIES

Partnership, acquisitions, and new product launches were found to be the major strategies adopted by the players operating in the global ceramic matrix composites market.

- In 2019, SGL Carbon extended its contract with Elbe Flugzeugwerke to supply impregnated carbon fiber textiles for use in airbus a350 cabin’s floor panels to end of 2020.

- In April 2023, SGL Carbon announced a new partnership with Lancer Systems to develop ceramic matrix composites for use in the thermal protection systems.

- In January 2023, Rolls-Royce signed a Memorandum of Understanding with the University of Sheffield in the UK to collaborate on the development of new ceramic matrix composites materials.

Ceramic Matrix Composites Market Regional Insights

Ceramic Matrix Composites Market Regional Insights

The regional trends and factors influencing the Ceramic Matrix Composites Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Ceramic Matrix Composites Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Ceramic Matrix Composites Market

Ceramic Matrix Composites Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2018 | US$ 8.56 Billion |

| Market Size by 2027 | US$ 18.49 Billion |

| Global CAGR (2018 - 2027) | 9.1% |

| Historical Data | 2016-2017 |

| Forecast period | 2019-2027 |

| Segments Covered |

By Product

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

Ceramic Matrix Composites Market Players Density: Understanding Its Impact on Business Dynamics

The Ceramic Matrix Composites Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Ceramic Matrix Composites Market are:

- COI Ceramics, Inc.

- General Electric Company

- Lancer Systems

- SGL Carbon

- Rolls-Royce Plc

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Ceramic Matrix Composites Market top key players overview

IMPACT OF COVID

The COVID-19 pandemic has had a significant impact on the ceramic matrix composites (CMCs) market, causing disruptions and hindering market growth. The pandemic led to widespread economic uncertainty, supply chain disruptions, and reduced industrial activities across various sectors. Many end-user industries of CMCs, such as aerospace, automotive, and energy, faced significant setbacks, including production halts, project delays, and reduced investments. The restrictions on travel and trade also affected the demand for CMCs in global markets. Moreover, the financial constraints faced by businesses and the focus on cost-cutting measures resulted in reduced capital expenditure and a cautious approach towards adopting advanced materials like CMCs. Although the market is expected to recover gradually as economies reopen and industrial activities resume, the COVID-19 pandemic has certainly impeded the growth trajectory of the CMCs market in the short term.

COMPETITIVE LANDSCAPE AND KEY COMPANIES

Some of the key players operating in the ceramic matrix composites market include COI Ceramics, Inc.; General Electric Company; Lancer Systems; SGL Carbon; Rolls-Royce Plc; CoorsTek, Inc.; Applied Thin Films Inc.; Ultramet; CFCCARBON CO, LTD; and Matech among others.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

- Queue Management System Market

- Extracellular Matrix Market

- Constipation Treatment Market

- Airport Runway FOD Detection Systems Market

- Electronic Health Record Market

- Skin Tightening Market

- Excimer & Femtosecond Ophthalmic Lasers Market

- Non-Emergency Medical Transportation Market

- Transdermal Drug Delivery System Market

- Smart Locks Market

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Product ; End-use Industry and Geography

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

US, Canada, Mexico, UK, Germany, Spain, Italy, France, India, China, Japan, South Korea, Australia, UAE, Saudi Arabia, South Africa, Brazil, Argentina

Frequently Asked Questions

Global ceramic matrix composites market in oxides product is expected to grow at a CAGR of 8.7% during the forecast period 2019 – 2027.

The oxides ceramic matrix composites are gaining increasing importance as a mainstream material alternative for the high-temperature components, mainly in the industrial, advanced energy and aerospace sectors. These materials are known to compete with other alternatives such as titanium in terms of cost-reductions. The oxide ceramic matrix composites have significant potential in the oxidation sensitive component applications. The demand for oxide ceramic matrix composites has been growing considerably in the aerospace sector for turbine engines and other high-temperature components. The oxide ceramic matrix composites have excellent thermal and mechanical properties coupled with damage-tolerant quasi ductile fracture behavior, which has been a significant factor for its application in the high temperature processes. Another supporting factor that has led to increasing demand for the oxide-ceramic matrix composites is its low weight and prolonged service lifetime. The oxide-ceramic matrix composites components such as changing racks, lift gates, or flame tubes have represented their potential in varied industrial high-temperature applications. The O-ceramic matrix composites components for gas turbines are currently being tested and developed. The oxide-ceramic matrix composites are light in weight due to their reduced density and mass. The increase in thermal efficiency and reduced maintenance cost have been a contributing factor to favor the oxide-ceramic matrix composites market all over the globe.

Ceramic Matrix Composites (CMC) are the materials consisting of a ceramic matrix combined with ceramic oxides or carbides. Ceramic materials are inorganic and nonmetallic solids, which are crystalline. They exhibit improved crack resistance and do not rupture easily under heavy loads as compared to conventional technical ceramics. Ceramic matrix composites reinforced by either continuous long fibers or discontinuous short fibers. High mechanical strength, high stiffness, high thermal and shock resistance, high thermal stability, high corrosion resistance, and lightweight making them suitable for the number of applications in aerospace & defense, automotive, energy, and power industries.

These favorable characteristics of the ceramic matrix composites is helping the product to grow and is being considered in a wide range of end user industry.

The North American region led the ceramic matrix composites market in 2018. North America comprises developed and developing countries such as the US, Canada, and Mexico. North America will account for a remarkable share in the ceramic matrix composites market owing to the rigorous growth of aerospace and defense spending in the region. Over the forecast period, the commercial aerospace sector is also expected to gain significant movement. Rigorous research and development activities by the United States Environmental Protection Agency (USEPA) for developing renewable energy sources are expected to create lucrative opportunities for ceramic matrix composites market in the region. Further, North America region has the existence of several ceramic matrix composite manufacturers such as COI Ceramics, INC. and Applied Thin Films, Inc., which are mainly focused on the adoption of various business strategies for increasing their production capacity.

Trends and growth analysis reports related to Chemicals and Materials : READ MORE..

The List of 10 Companies - Ceramic Matrix Composites Market

- COI Ceramics, Inc.

- General Electric Company

- Lancer Systems

- SGL Carbon

- Rolls-Royce Plc

- Coorstek, Inc.

- Applied Thin Films Inc.

- Ultramet

- CFC Carbon Co,. Ltd

- Matech

Get Free Sample For

Get Free Sample For