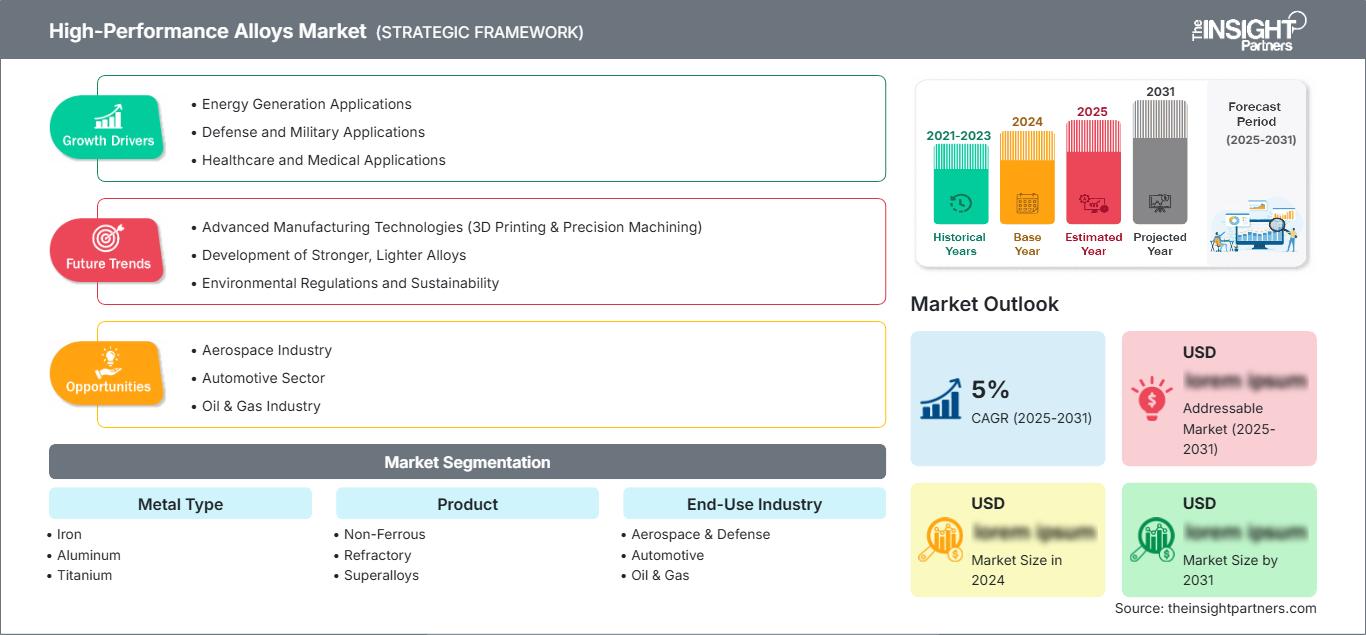

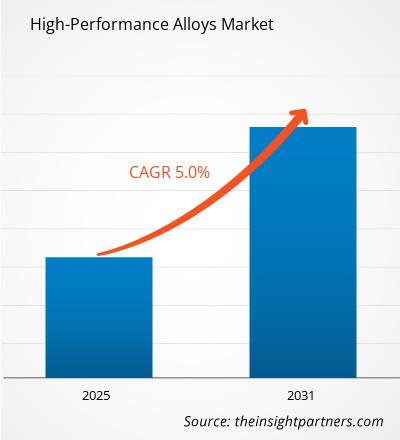

The High-Performance Alloys Market is expected to register a CAGR of 5% from 2025 to 2031, with a market size expanding from US$ XX million in 2024 to US$ XX Million by 2031.

High-Performance Alloys Market covers analysis By Metal Type (Iron, Aluminum, Titanium, Magnesium, and Others), Product (Non-Ferrous, Refractory, Superalloys, and Others), End-Use Industry (Aerospace & Defense, Automotive, Oil & Gas, Industrial, Electrical & Electronics, and Others) and Geography (North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America). High-k dielectric material is defined as the material which has high dielectric constant k. These materials are principal insulators where negligible current flows from the material during the application of voltage through it. The growing demand of microelectronics and Increase in the requirement of low thermal stable materials will boost the high-k dielectric material market in the forecast period.

Purpose of the Report

The report High-Performance Alloys Market by The Insight Partners aims to describe the present landscape and future growth, top driving factors, challenges, and opportunities. This will provide insights to various business stakeholders, such as:

- Technology Providers/Manufacturers: To understand the evolving market dynamics and know the potential growth opportunities, enabling them to make informed strategic decisions.

- Investors: To conduct a comprehensive trend analysis regarding the market growth rate, market financial projections, and opportunities that exist across the value chain.

- Regulatory bodies: To regulate policies and police activities in the market with the aim of minimizing abuse, preserving investor trust and confidence, and upholding the integrity and stability of the market.

High-Performance Alloys Market Segmentation

Metal Type

- Iron

- Aluminum

- Titanium

- Magnesium

Product

- Non-Ferrous

- Refractory

- Superalloys

End-Use Industry

- Aerospace & Defense

- Automotive

- Oil & Gas

- Industrial

- Electrical & Electronics

Geography

- North America

- Europe

- Asia-Pacific

- South and Central America

- Middle East and Africa

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

High-Performance Alloys Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

High-Performance Alloys Market Growth Drivers

- Energy Generation Applications: High-performance alloys find extensive applications in energy generation devices such as gas turbines, nuclear energy reactors, and energy storage devices since these materials can sustain very high temperatures and very aggressive environments. This scenario has led to the increase in the need for performance alloys in the energy production systems considering the global energy levels growth.

- Defense and Military Applications: High-performance alloys are also used in non-commercial applications such as defence, where it is demanding to retain strength and hardness alongside extreme conditions. Gisic, improvement of military technologies, and increased military budgets across countries have sustained demand for weapons, body armor, or aircraft made of high-performance alloys.

- Healthcare and Medical Applications: In the industrial as well as in the nuclear medical, high-performance titanium and cobalt alloys are used for implants and surgical instruments because of their biocompatibility, high strength, and corrosion resistance. Hence, as a result of growth of the global healthcare market, there is a growing need for high performance alloys in the medical market.

High-Performance Alloys Market Future Trends

- Advanced Manufacturing Technologies (3D Printing & Precision Machining): The present circumstances call for the need of high-performance alloys with the recent activities and development of advanced manufacturing technologies such as 3D printing and precision machining. It is crucial where low-machined metallic parts are used in aerospace, automotive, and industrial equipment, especially in areas where complex parts are expected to have higher strength, heat and wear resistance.

- Development of Stronger, Lighter Alloys: Due to modern technology, there is invention of stronger, heat resistant and lighter alloys in material science. This widened their usage. Consequently, the new high-performance alloys which are improving properties for use in critical industries are on the rise growth of the aerospace, automotive and energy industries.

- Environmental Regulations and Sustainability: Stricter environmental regulations and the ever-increasing necessity for more sustainable production processes demand the use of high-performance alloys with better energy efficiency, longer durability, and higher recyclability. These help industries meet the regulatory standards imposed and minimize environmental impact, giving the grounds for adopting them in sectors such as automotive and manufacturing.

High-Performance Alloys Market Opportunities

- Aerospace Industry: Tough alloys such as titanium and nickel-based alloys are essential in aerospace applications once high temperatures and stress conditions are considered. Growth of the aerospace sector is witnessed as a result of increased air travel and defense spending which in turn has led to a need in high-performance alloys for components of aircraft and space vehicles.

- Automotive Sector: Another example can be drawn from the automotive sector where safety concerns and the quest for fuel economy has led to a craving of lightweight, high-strength material which in turn has increased the use of high performance alloys. These are being used in important parts like the engine, in the transmission systems and in the structural sections of vehicles to enhance performance, provide durability, lessen the weight of the vehicle, especially in electric cars.

- Oil & Gas Industry: High-performance alloys, in particular corrosion-resistant alloys, are vital for uses in drilling, pipelines, and offshore platforms in the oil and gas industries. With expanding exploration and production in harsh environments, a fast-rising requirement for alloys with higher tolerance to extreme temperature as well as corrosive conditions is witnessed.

High-Performance Alloys Market Regional Insights

The regional trends and factors influencing the High-Performance Alloys Market throughout the forecast period have been thoroughly explained by the analysts at The Insight Partners. This section also discusses High-Performance Alloys Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

High-Performance Alloys Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ XX million |

| Market Size by 2031 | US$ XX Million |

| Global CAGR (2025 - 2031) | 5% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Metal Type

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

High-Performance Alloys Market Players Density: Understanding Its Impact on Business Dynamics

The High-Performance Alloys Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

- Get the High-Performance Alloys Market top key players overview

Key Selling Points

- Comprehensive Coverage: The report comprehensively covers the analysis of products, services, types, and end users of the High-Performance Alloys Market, providing a holistic landscape.

- Expert Analysis: The report is compiled based on the in-depth understanding of industry experts and analysts.

- Up-to-date Information: The report assures business relevance due to its coverage of recent information and data trends.

- Customization Options: This report can be customized to cater to specific client requirements and suit the business strategies aptly.

The research report on the High-Performance Alloys Market can, therefore, help spearhead the trail of decoding and understanding the industry scenario and growth prospects. Although there can be a few valid concerns, the overall benefits of this report tend to outweigh the disadvantages.

Frequently Asked Questions

Based on geography, which region is expected to record a highest CAGR in the market.

Which end use segment accounted for the highest share in the high-performance alloys market?

What are the key players operating in the high-performance alloys market?

What are the driving factors impacting the high-performance alloys market?

What is the expected CAGR of the High-Performance Alloys Market ?

What are the future trends in the market?

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Recent Reports

Related Reports

Testimonials

Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For