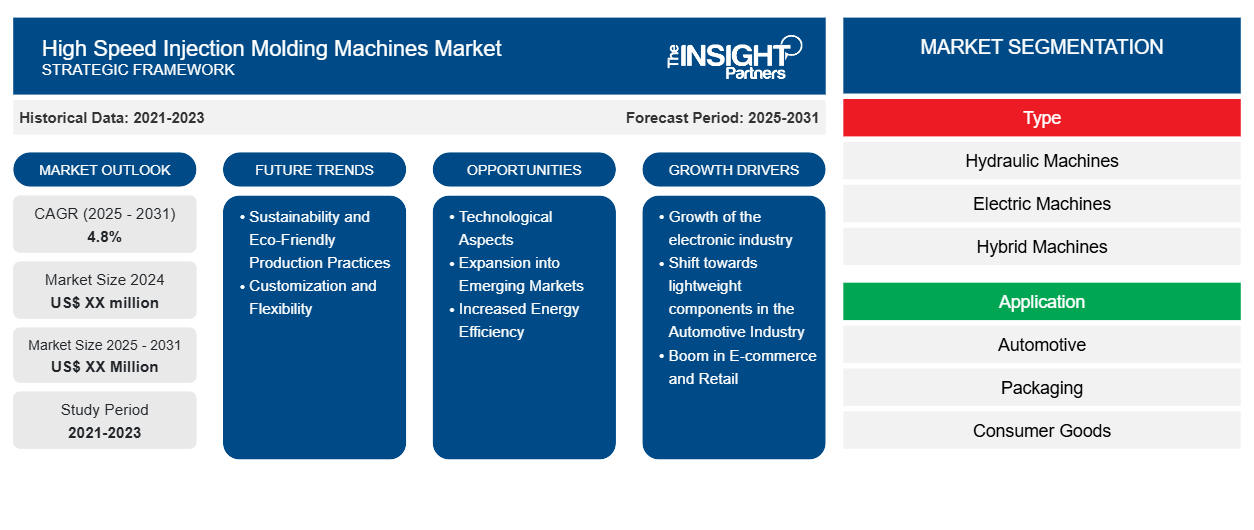

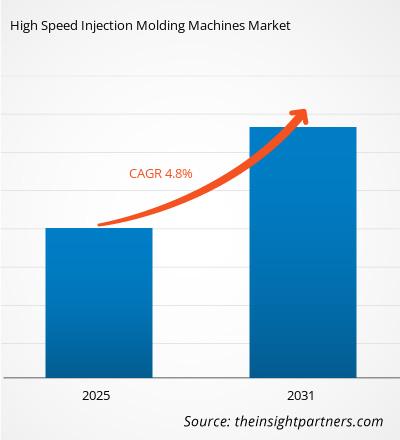

The High Speed Injection Molding Machines Market is expected to register a CAGR of 4.8% from 2025 to 2031, with a market size expanding from US$ XX million in 2024 to US$ XX Million by 2031.

The market is segmented into by Type, and Application. The Type segment is divided into Hydraulic Machines, Electric Machines, and Hybrid Machines. Based on Application, the market is segmented into Automotive, Packaging, Consumer Goods, Healthcare, Electronics, and Others.

Purpose of the Report

The report High Speed Injection Molding Machines Market by The Insight Partners aims to describe the present landscape and future growth, top driving factors, challenges, and opportunities. This will provide insights to various business stakeholders, such as:

- Technology Providers/Manufacturers: To understand the evolving market dynamics and know the potential growth opportunities, enabling them to make informed strategic decisions.

- Investors: To conduct a comprehensive trend analysis regarding the market growth rate, market financial projections, and opportunities that exist across the value chain.

- Regulatory bodies: To regulate policies and police activities in the market with the aim of minimizing abuse, preserving investor trust and confidence, and upholding the integrity and stability of the market.

High Speed Injection Molding Machines Market Segmentation

Type

- Hydraulic Machines

- Electric Machines

- Hybrid Machines

Application

- Automotive

- Packaging

- Consumer Goods

- Healthcare

- Electronics

- Others

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

High Speed Injection Molding Machines Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

High Speed Injection Molding Machines Market Growth Drivers

- Growth of the electronic industry: Growing consumer demand for consumer electronics, which include smartphones, wearables, computers, and home appliances, is a great reason for the growth of injection molding machines. As electronics grow smaller, lighter, and packed with more features, the requirement for precision molded components, like casings, connectors, and housings, has dramatically increased. Injection molding, owing to its capability to provide high-precision, complex geometries at high volumes, remains an ideal manufacturing process for making parts for use in electronics.

- Shift towards lightweight components in the Automotive Industry: The automobile industry is in the present focus on producing a lightweight car for better mileage and emissions compliance. Because of the need for lower weight to enhance mileage and comply with emissions standards, the market for injection-molded plastics has witnessed a boom. Injection molders create plastic parts such as interior parts, dashboard, bumper, and door panels within the shortest span of time.

- Boom in E-commerce and Retail: In recent years, the e-commerce sector has grown enormously, thereby raising the demand for packaging materials. Injection molding machines are extensively used to manufacture plastic packaging in the form of containers, bottles, caps, and trays. The need for efficient, cost-effective, and eco-friendly packaging solutions is pushing the demand for injection-molded packaging products.

High Speed Injection Molding Machines Market Future Trends

- Sustainability and Eco-Friendly Production Practices: The interest in sustainable manufacturing practices is now steadily increasing. For this reason, companies are marketing the use of eco-friendly manufacturing to customers. Among some of the high-speed injection molding machines designed, which will be produced using recyclable materials and less energy consumption, this feature will come with the capability to meet environment as well as consumer expectations.

- Customization and Flexibility: Customization is the new talk of the town for production lines these days. Manufacturers are looking for flexible solutions that can accept changes and adapting capabilities for various production needs. High-speed injection moulding machines with modular designs and quick changeover facilities are required to help businesses efficiently produce diversified products without requiring considerable downtime

High Speed Injection Molding Machines Market Opportunities

- Technological Aspects: High-speed injection moulding technology has a much higher opportunity for innovation. Improved automation, energy efficiency, and smart technologies would give manufacturers the competitive edge in comparison with other producers as well as attract customers who are looking for state-of-the-art solutions.

Expansion into Emerging Markets: There is high growth in industrial sectors in emerging economies, which thus invest more in manufacturing capabilities. This provides an excellent platform for the high-speed injection moulding machine manufacturer to expand its markets with this demand for more productive production processes. - Increased Energy Efficiency: Electric injection molding machines, which provide significant energy savings and precision compared to hydraulic machines, are expected to dominate the market. The increasing demand for energy-efficient manufacturing processes, which is driven by increasing energy costs and sustainability goals, will speed up the adoption of electric IMM. These machines provide better control over speed, temperature, and pressure, reducing energy consumption and minimizing environmental impact.

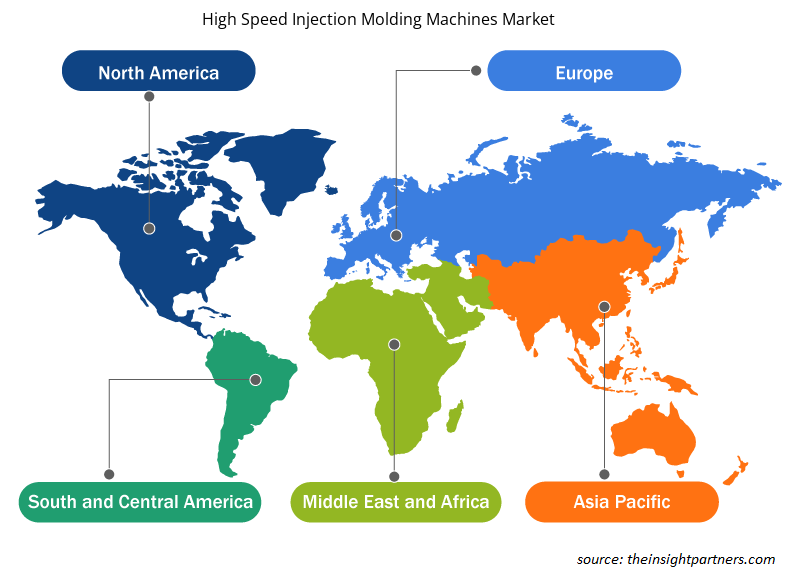

High Speed Injection Molding Machines Market Regional Insights

The regional trends and factors influencing the High Speed Injection Molding Machines Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses High Speed Injection Molding Machines Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for High Speed Injection Molding Machines Market

High Speed Injection Molding Machines Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ XX million |

| Market Size by 2031 | US$ XX Million |

| Global CAGR (2025 - 2031) | 4.8% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

High Speed Injection Molding Machines Market Players Density: Understanding Its Impact on Business Dynamics

The High Speed Injection Molding Machines Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the High Speed Injection Molding Machines Market are:

- Sumitomo Demag

- Fanuc Corporation

- Writtmann Battenfeld

- Haitian International Holdings Ltd.

- Arburg

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the High Speed Injection Molding Machines Market top key players overview

Key Selling Points

- Comprehensive Coverage: The report comprehensively covers the analysis of products, services, types, and end users of the High Speed Injection Molding Machines Market, providing a holistic landscape.

- Expert Analysis: The report is compiled based on the in-depth understanding of industry experts and analysts.

- Up-to-date Information: The report assures business relevance due to its coverage of recent information and data trends.

- Customization Options: This report can be customized to cater to specific client requirements and suit the business strategies aptly.

The research report on the High Speed Injection Molding Machines Market can, therefore, help spearhead the trail of decoding and understanding the industry scenario and growth prospects. Although there can be a few valid concerns, the overall benefits of this report tend to outweigh the disadvantages.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

- Digital Language Learning Market

- Green Hydrogen Market

- Enzymatic DNA Synthesis Market

- Energy Recovery Ventilator Market

- Sodium Bicarbonate Market

- Molecular Diagnostics Market

- Electronic Signature Software Market

- Lyophilization Services for Biopharmaceuticals Market

- Transdermal Drug Delivery System Market

- Enteral Nutrition Market

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

This text is related

to segments covered.

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

This text is related

to country scope.

Frequently Asked Questions

The leading players includes Sumitomo (SHI) Demag Plastics Machinery GmbH, Fanuc, WITTMANN Group, Haitian International, ARBURG, ENGEL, NISSEI PLASTIC INDUSTRIAL CO., LTD., JSW Plastics Machinery, KAIMING, Negri Bossi

The report can be delivered in PDF/PPT format; we can also share excel dataset based on the request.

Some of the customization options available based on the request are an additional 3-5 company profiles and country-specific analysis of 3-5 countries of your choice. Customizations are to be requested/discussed before making final order confirmation, as our team would review the same and check the feasibility.

Presence of alternative products

The major factors driving the High Speed Injection Moilding Machine market are: Growing demand lightweight parts

The High Speed Injection Molding Machines Market Size and Forecasts (2021 - 2031), Global and Regional Share, Trends, and Growth Opportunity Analysis Report Coverage:by Type (Hydraulic Machines, Electric Machines, and Hybrid Machines); Application (Automotive, Packaging, Consumer Goods, Healthcare, Electronics, and Others), and Geography (North America, Europe, Asia Pacific, and South and Central America) is estimated to witness a CAGR of 4.8% from 2023 to 2031

Trends and growth analysis reports related to Manufacturing and Construction : READ MORE..

1. Sumitomo Demag

2. Fanuc Corporation

3. Writtmann Battenfeld

4. Haitian International Holdings Ltd.

5. Arburg

6. Engel

7. Nissei Plastic

8. JSW Plastics Machinery

9. Guangdong Kaiming Engineering

10. Negri Bossi

Get Free Sample For

Get Free Sample For