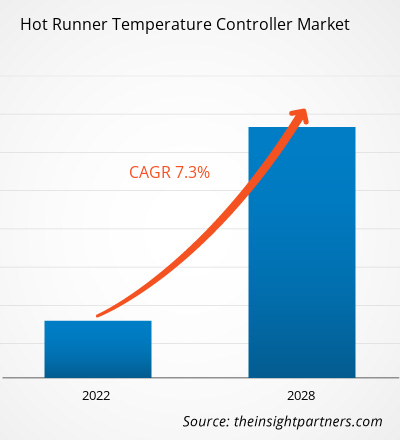

The hot runner temperature controller market is expected to grow from US$ 124.31 million in 2021 to US$ 203.17 million by 2028; it is estimated to grow at a CAGR of 7.3% during 2021–2028.

Plastic is transformed from a raw material to a proper form using hot runner controllers. Demand for hot runner temperature controller Market has increased with surge in the need for molded plastic in the automotive, home appliance, electrical, and electronics industries. Due to the suitability of versatile plastic components in flexible packaging, pipelines, insulation and coatings, and medical devices, customers’ demand for hot runner temperature controller devices is on rise. Furthermore, increased demand from the construction industry due to the widespread use of injection-molded plastics in flooring, roofing, pipelines, walls, insulation, and windows has boosted the demand.

Injection molding is one of the most widely used plastics manufacturing processes, as it is capable of providing a realistic solution for the mass production of high-quality injection automobile parts from various polymers. Automotive plastic injection molding is a critical production technique in the automotive sector, where consistency, safety, and quality are crucial. Medical plastic parts are subjected to rigorous quality checks in all the phases, ranging from the prototype phase through high-volume production phase. Disposable packaging, syringes, petri dishes, and test tubes are among the medical products available, as are parts for sensors, diagnostic equipment, and plastic implants. Medical-grade plastics feature a wide range of properties; a majority of these are delicate and can only be manufactured within a narrow processing window. Mold Hotrunner Solutions Inc., for instance, offers high-performance hot runner systems named Rheo-Pro for producing medical parts. Thus, the use of hot runners significantly reduces production costs by eliminating the requirement of cold runners, and related part handling and regrind materials.

Furthermore, plastic injection-molded parts are subject to stringent regulations in the packaging business. Thin-walled, lightweight molded parts, as well as the maximum manufacturing capacity, are examples of this. MHS offers a variety of plastic injection molding options, including thin-walled containers and closures as well as PET bottle preform molds, for high-volume packaging. Plastics play a significant role in the building industry's evolution; items made from this material are increasingly being used by architects, engineers, and developers due to their material properties, strength, appearance, manufacturability, and durability. MHS provides injection molding solutions for various applications, including flooring systems, roofing, siding, fence, irrigation, plumbing, fittings, fasteners, and machines.

Thus, the growing use of molded plastics in automotive, medical devices, construction, and packaging industries is boosting the hot runner temperature controller market growth.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Hot Runner Temperature Controller Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Hot Runner Temperature Controller Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Impact of COVID-19 Pandemic on North America Hot Runner Temperature Controller Market

The COVID-19 pandemic hit almost all industries across the world in FY 2020 due to lockdown measures imposed by various countries, which disrupted supply chain of different industries as well as generated a demand & supply gap in different industries. The packaging industry in North America has faced many challenges due to suspended or disturbed operations in the food & beverages, automotive, and medical industries. Assembly plants and supplier facilities in different countries in North America were closed in March and May 2020. Moreover, restrictions enacted on transportation and logistics operations created further challenges for industrial operations. Slowdown in industrial manufacturing and delays in scheduled periodic equipment maintenance activities across different facilities further caused a stir in the industrial sector, further lowering the demand for hot runner temperature controller systems.

Further, consumer habits have changed during the COVID-19 pandemic owing to a surge in preference for home delivery of food and other products that has led to a great requirement of packaging materials such as plastics. Therefore, the requirement of the large amount of plastic production is increasing across the region. Also, decline in investments across industrial facilities, amid the industrial crisis, has hindered the growth of the industrial automation technologies.

Hot Runner Temperature Controller Market Insights

Progress of IoT and Industry 4.O

Industry 4.0 and the Internet of Things (IoT) play a vital role in the automation and plastic molding processes. Technological enhancements such as integrating linked devices with the Internet of Things (IoT) and smart sensors are among the key factors contributing to the hot runner temperature controller market growth. These cutting-edge technologies aid real-time data collection and analysis for the plastic molding process, lowering the risk of production flaws and errors. In molding, temperature controllers are utilized to modify valve pin timing, and monitor and manage the molding process. The incorporation of temperature and pressure sensors in molds maximizes molding efficiency, and it further indicates the ongoing innovations for improving the quality of various parts. Moreover, new electric valve gate technologies allow a faster response to valve pin opening. Furthermore, improved controller technologies make communication between the press and the valve pin working sequence easier. In-cavity sensor technologies also enable hot runner systems to adjust to differences between the viscosities of various materials. As the industry transitions to bio-resins, these viscosity variances may become much more pronounced, necessitating the use of closed-loop communication to regulate temperatures inside the hot runner system, thereby bringing more stability in the process.

The features of profiTEMP+ hot-runner temperature controller offered by Meusburger make the setup more accessible and enable the Industry 4.0 capability on the back of a new connection for a radio-frequency identification (RFID) reader; a new setup wizard makes system configuration easier. The RFID reader and connection allow enhanced communication and information-sharing capabilities to numerous equipment and devices, which helps firms in transition toward Industry 4.0. Other factors, including the introduction of Industry 4.0 and favorable government regulations for the use of lightweight plastic molding systems, are expected to further propel the industry growth in the coming years.

Type - Based Market Insights

Based on type, the hot runner temperature controller market is bifurcated into valve gate hot runner and open gate hot runner. In 2020, the valve gate hot runner segment led the market, accounting for a larger market share.

Application - Based Market Insights

Based on application, the hot runner temperature controller market is segmented into automotive industry, electronic industry, medical industry, packaging industry, and others. In 2020, the packaging industry segment accounted for the largest market share.

Control Zone-Based Market Insights

Based on control zone, the hot runner temperature controller market is segmented into up to 12 zones, 12–48 zones, 48–72 zones, 72–108 zones, 108–144 zones, 144–180 zones, 180–216 zones, and above 216 zones. In 2020, the 12–48 zones segment accounted for the largest market share.

The players operating in the hot runner temperature controller market adopt strategies such as mergers, acquisitions, and market initiatives to maintain their positions in the market. A few developments by key players are listed below:

- In June 2021, Husky Injection Molding Systems, Ltd., a leading industrial technology provider to the plastics processing community, partnered with Chem-Trend on a system solution that creates repeatability during the critical color change process, allowing operators to work faster, more accurately, and more efficiently. Within the Husky Altanium Mold Controller operator interface, the team designed a novel guided method that is easily accessible to operators. The instructions specifically for moulds with hot runner systems detail a simple, yet extremely successful technique to set up and complete the color change procedure.

- In October 2019, EWIKON HEIßKANALSYSTEME GMBH launched a new EWIKON pro CONTROL range of hot runner controllers. The competent EWIKON pro CONTROL series of hot runner controllers enables comfortable, reliable, and precise control of hot runner system with intuitive and self-explanatory touch screen operation. Pro Regulate is generally suitable for ordinary applications and demanding high-cavitation systems with small and low-mass hot runner nozzles that are difficult to control due to its rapid control behavior.

Hot Runner Temperature Controller Market Regional Insights

The regional trends and factors influencing the Hot Runner Temperature Controller Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Hot Runner Temperature Controller Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Hot Runner Temperature Controller Market

Hot Runner Temperature Controller Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2021 | US$ 124.31 Million |

| Market Size by 2028 | US$ 203.17 Million |

| Global CAGR (2021 - 2028) | 7.3% |

| Historical Data | 2019-2020 |

| Forecast period | 2022-2028 |

| Segments Covered |

By Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

Hot Runner Temperature Controller Market Players Density: Understanding Its Impact on Business Dynamics

The Hot Runner Temperature Controller Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Hot Runner Temperature Controller Market are:

- EMI Corporation

- EWIKON HEIßKANALSYSTEME GMBH

- Gammaflux

- GÜNTHER Heisskanaltechnik GmbH

- Husky Injection Molding Systems Ltd.

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Hot Runner Temperature Controller Market top key players overview

The global hot runner temperature controller market has been segmented as mentioned below:

By Type

- Valve Gate Hot Runner

- Open Gate Hot Runner

By Application

- Automotive Industry

- Electronic Industry

- Medical Industry

- Packaging Industry

- Others

By Control Zone

- Up to 12 Zones

- 12–48 Zones

- 48–72 Zones

- 72–108 Zones

- 108–144 Zones

- 144–180 Zones

- 180–216 Zones

- Above 216 Zones

By Geography

North America

- US

- Canada

- Mexico

Europe

- France

- Germany

- Italy

- UK

- Russia

- Rest of Europe

Asia Pacific (APAC)

- China

- India

- South Korea

- Japan

- Australia

- Rest of APAC

Middle East & Africa (MEA)

- South Africa

- Saudi Arabia

- UAE

- Rest of MEA

South America (SAM)

- Brazil

- Argentina

- Rest of SAM

Company Profiles

- EMI Corporation

- EWIKON HEIßKANALSYSTEME GMBH

- Gammaflux

- GÜNTHER Heisskanaltechnik GmbH

- Husky Injection Molding Systems Ltd.

- Meusburger Georg GmbH & Co KG

- Mold Hotrunner Solutions Inc.

- FISA Corporation

- INGLASS S.P.A.

- HILLENBRAND, INC. (MOLD-MASTERS)

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

- Educational Furniture Market

- Flexible Garden Hoses Market

- Sodium Bicarbonate Market

- Vision Guided Robotics Software Market

- Virtual Pipeline Systems Market

- Water Pipeline Leak Detection System Market

- Formwork System Market

- GMP Cytokines Market

- Small Molecule Drug Discovery Market

- Genetic Testing Services Market

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Type, Application and Control Zone

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

Argentina, Australia, Brazil, Canada, China, France, Germany, India, Italy, Japan, Mexico, Russian Federation, Saudi Arabia, South Africa, South Korea, United Arab Emirates, United Kingdom, United States

Frequently Asked Questions

Based on application, the hot runner temperature controller market can be segmented into automotive industry, electronic industry, medical industry, packaging industry, and others. In 2020, the packaging industry segment accounted for the largest market share.

In 2020, North America led the market with a substantial revenue share, followed by Asia Pacific and Europe. North America is a prospective market for hot runner temperature controller manufacturers.

ABIMAN GROUP (Yudo Group), Husky Injection Molding Systems Ltd., HILLENBRAND, INC., ARICO TECHNOLOGY CO., LTD., and Meusburger Georg GmbH & Co KG among others are the five key market players operating in the hot runner temperature controller market.

Based on type, the hot runner temperature controller market is segmented into valve gate hot runner and open gate hot runner. In 2020, the valve gate hot runner segment led the hot runner temperature controller market, accounting for the largest share in the market.

The market opportunity lies in developing countries. Developing countries have become a hub of opportunity for various markets, including hot runner temperature controller market. Thus, the progress of IoT and industry 4.O and adoption of new generation multizone hot runner controller technology are presenting significant potential for the future growth of the hot runner temperature controller market players.

Growing use of molded plastics in automotive, medical devices, construction, & packaging industries and shortening of cycle time and reduction of plastic waste are driving the growth of the hot runner temperature controller market. These factors are propelling the adoption of hot runner temperature controller in various industries.

Trends and growth analysis reports related to Electronics and Semiconductor : READ MORE..

The List of Companies - Hot Runner Temperature Controller Market

- EMI Corporation

- EWIKON HEIßKANALSYSTEME GMBH

- Gammaflux

- GÜNTHER Heisskanaltechnik GmbH

- Husky Injection Molding Systems Ltd.

- Meusburger Georg GmbH & Co KG

- Mold Hotrunner Solutions Inc.

- FISA Corporation

- INGLASS S.P.A.

- HILLENBRAND, INC. (MOLD-MASTERS)

Get Free Sample For

Get Free Sample For