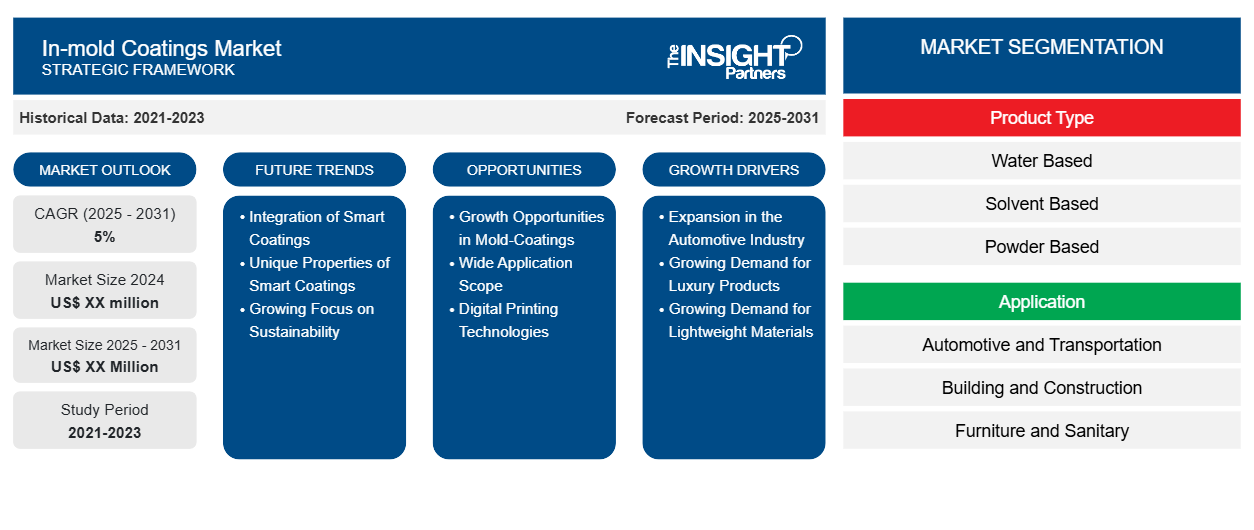

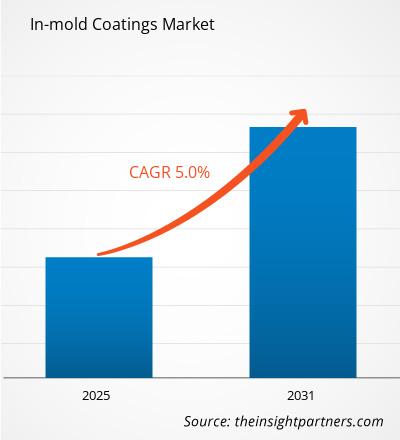

The In-mold Coatings Market is expected to register a CAGR of 5% from 2025 to 2031, with a market size expanding from US$ XX million in 2024 to US$ XX Million by 2031.

The report presents analysis based on product type (water based, solvent based, and powder based). The report is segmented by application (automotive and transportation, building and construction, furniture and sanitary, electronics, medical, and others). The global analysis is further broken-down at regional level and major countries. The market size and forecast at global, regional, and country levels for all the key market segments are covered under the scope. The report offers the value in USD for the above analysis and segments. The report provides key statistics on the market status of the key market players and offers market trends and opportunities.

Purpose of the Report

The report In-mold Coatings Market by The Insight Partners aims to describe the present landscape and future growth, top driving factors, challenges, and opportunities. This will provide insights to various business stakeholders, such as:

- Technology Providers/Manufacturers: To understand the evolving market dynamics and know the potential growth opportunities, enabling them to make informed strategic decisions.

- Investors: To conduct a comprehensive trend analysis regarding the market growth rate, market financial projections, and opportunities that exist across the value chain.

- Regulatory bodies: To regulate policies and police activities in the market with the aim of minimizing abuse, preserving investor trust and confidence, and upholding the integrity and stability of the market.

In-mold Coatings Market Segmentation

Product Type

- Water Based

- Solvent Based

- Powder Based

Application

- Automotive and Transportation

- Building and Construction

- Furniture and Sanitary

- Electronics

- Medical

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

In-mold Coatings Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

In-mold Coatings Market Growth Drivers

- Expansion in the Automotive Industry: The growth of the automotive industry is highly driving the market for in-mold coatings. Automotive manufacturers are looking for ways to enhance aesthetics and durability in vehicles. In-mold coatings enable the realization of complex designs and finishes directly during the molding process, thereby increasing efficiency and reducing the need for secondary operations.

- Growing Demand for Luxury Products: As more consumers are seeking to possess fashionable, high-performance cars, the focus for automobile manufacturers lies in the development of innovative new materials and finishes. Coatings in mold have resistance properties against chemical substances and UV light, making them the favorite choice for automotive applications. This shift toward advanced coatings does not only add up the quality of products but also appeals to consumers in a competitive marketplace.

- Growing Demand for Lightweight Materials: Further, the requirement for lighter-weight materials in the automotive sector drives this in-mold coatings market. Automotive companies tend towards producing more lightweight parts, so these help to drive better performance and improve their fuel economy. This makes them carry the structural strength along with a visually aesthetic surface as well. It brings in sustainability goals from this viewpoint as well, which supports their high demand even in automobile production lines as well.

In-mold Coatings Market Future Trends

- Integration of Smart Coatings: The integration of smart coatings is emerging as one of the significant trends in the in-mold coatings market. Smart coatings can be defined as a system that responds to environmental changes and offers functionality beyond what conventional coatings can provide. Some examples of properties that make them so attractive in various applications, such as automotive and consumer goods, include change in color, self-healing, and enhanced protection.

- Unique Properties of Smart Coatings: Another uniqueness of smart coatings is that they can avail themselves of product differentiation as this is one of the concerns of manufacturers. Sensors can be embedded inside for in-mold monitoring of temperature and humidity; therefore, real-time information on these conditions is obtained, which improves the performance of the product and enables proactive maintenance measures to be taken before it fails. This can be an attraction to industries where reliability and efficiency are a priority.

- Growing Focus on Sustainability: The more concerned people get about sustainability, the greater their interest in smart coatings, which can minimize waste and energy consumption. Examples include self-cleaning as well as anti-fogging properties, which reduce chemicals for cleaning and maintenance that contribute to unsustainable practices, thus making smart coatings preferable for manufacturers looking to boost their environmental performance.

In-mold Coatings Market Opportunities

- Growth Opportunities in Mold-Coatings: Technological advancements are creating vast growth opportunities in the in-mold coatings market. Materials science innovations have led to the development of advanced coatings that offer superior durability, scratch resistance, and chemical stability. These enhancements make in-mold coatings increasingly appealing to manufacturers in automotive, consumer goods, and industrial applications.

- Wide Application Scope: The application techniques can be further improved, for instance, automation and robotics, which have made the process of application of coatings easier at the manufacturing stage. They lessen production time and less waste is created. Hence, manufacturers are able to produce products in a more efficient manner. More use of automation would lead to a higher requirement for in-mold coatings with a better performance level to withstand powerful manufacturing processes.

- Digital Printing Technologies: Design capabilities are further transformed by the in-mold coatings and digital printing technologies. The resulting products enable customers to choose designs and finishes they might prefer based on changing preferences in their minds over time. For a brand, making exclusive products can become an attractive competitive edge for demand.

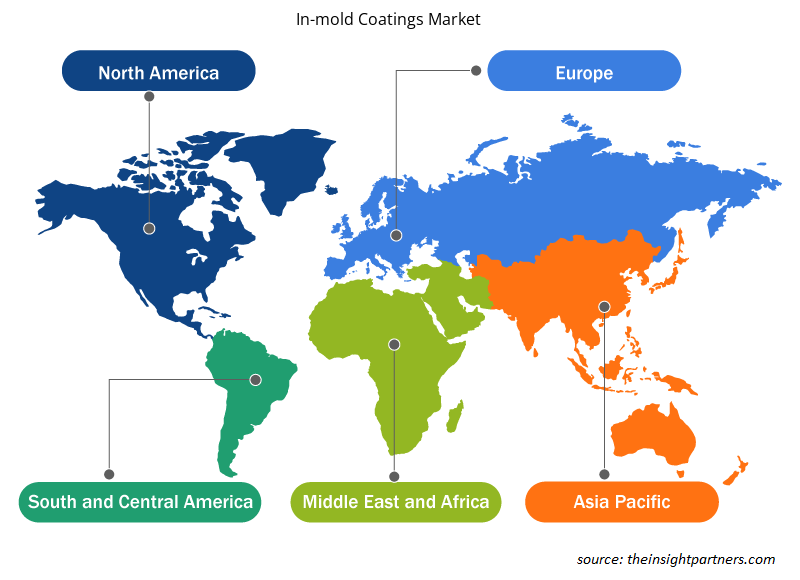

In-mold Coatings Market Regional Insights

The regional trends and factors influencing the In-mold Coatings Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses In-mold Coatings Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for In-mold Coatings Market

In-mold Coatings Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ XX million |

| Market Size by 2031 | US$ XX Million |

| Global CAGR (2025 - 2031) | 5% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Product Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

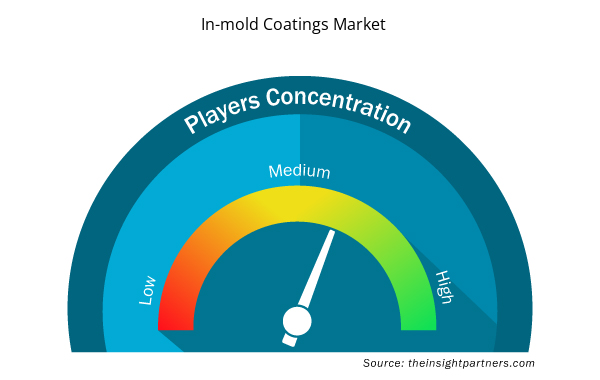

In-mold Coatings Market Players Density: Understanding Its Impact on Business Dynamics

The In-mold Coatings Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the In-mold Coatings Market are:

- BOMIX

- The Sherwin-Williams Company

- Plasti Dip UK Ltd

- Stahl Holdings B.V

- Fujichem Sonneborn Limited

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the In-mold Coatings Market top key players overview

Key Selling Points

- Comprehensive Coverage: The report comprehensively covers the analysis of products, services, types, and end users of the In-mold Coatings Market, providing a holistic landscape.

- Expert Analysis: The report is compiled based on the in-depth understanding of industry experts and analysts.

- Up-to-date Information: The report assures business relevance due to its coverage of recent information and data trends.

- Customization Options: This report can be customized to cater to specific client requirements and suit the business strategies aptly.

The research report on the In-mold Coatings Market can, therefore, help spearhead the trail of decoding and understanding the industry scenario and growth prospects. Although there can be a few valid concerns, the overall benefits of this report tend to outweigh the disadvantages.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

This text is related

to segments covered.

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

This text is related

to country scope.

Frequently Asked Questions

The integration of smart coatings is expected to be the key market trends.

Based on product type, the solvent based segment is expected to witness the fastest growth during the forecast period

Based on geography, Asia Pacific held the largest share of the in-mold coatings market due to the region has a robust automotive and manufacturing sector, with countries such as China, Japan, and India leading in production. The growing demand for lightweight and aesthetically pleasing components drives the need for advanced in-mold coatings.

The growth of the automotive industry are driving the market growth.

Bomix Chemie GmbH; Omnova Solutions Inc.; Akzo Nobel NV; Sherwin-Williams Company; Stahl Holdings BV; Red Spot Paint and Varnish Company Inc.; Emil Frei GmbH and Co. Kg.; Protech Powder Coatings Inc.; Adapta Color SL; and Plasti Dip International are some of the key players operating in the in-mold coatings market

The In-mold Coatings Market is estimated to witness a CAGR of 5% from 2023 to 2031

Trends and growth analysis reports related to Chemicals and Materials : READ MORE..

1. BOMIX

2. The Sherwin-Williams Company

3. Plasti Dip UK Ltd

4. Stahl Holdings B.V

5. Fujichem Sonneborn Limited

6. Red Spot Paint and Varnish Company, Inc

7. BERLAC GROUP

8. Protech Powder Coatings Inc.

9. KECK Chimie

10. Performix by Plasti Dip International

Get Free Sample For

Get Free Sample For