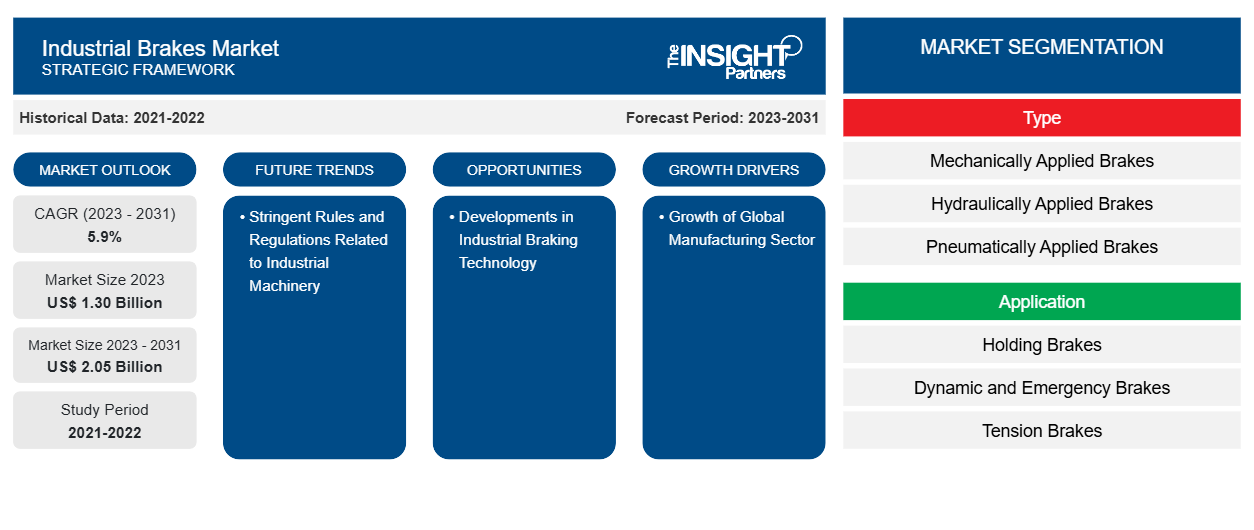

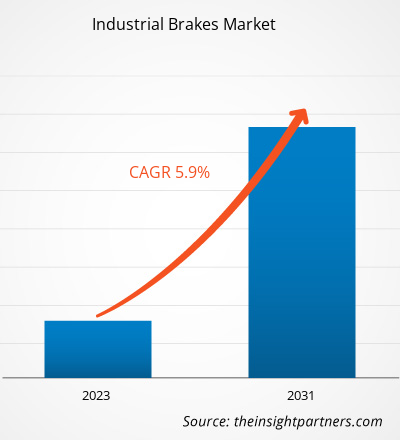

Industrial brakes market size is projected to reach US$ 2.05 billion by 2031 from US$ 1.30 billion in 2023. The market is expected to register a CAGR of 5.9% in 2023–2031.

An industrial brake is a frictional device used to halt a spinning inertia load or to retain a component in a fixed position. In most cases, the inertia load is caused by many spinning components that must be halted. To slow anything down, they transform the kinetic energy created by friction between two surfaces into heat. Industrial brakes differ from car brakes in that they are used in a variety of industrial machines. Industrial brakes work in all-weather situations, require less maintenance owing to fewer moving components, and are easy to modify for various applications. During the forecast period, all of these reasons are likely to boost the demand for industrial brakes across the world.

Industrial brakes provide numerous benefits, one of which is the low number of parts and spares needed. Other benefits include easy hygiene owing to the one-piece design, a high return on investment due to the extended life of industrial brakes, and the ability to work in harsh situations. Additionally, growing industrialization and increasing government investments in the industrial sectors to promote output are expected to have a substantial influence on the industrial brakes market during the projected period.

Industrial Brakes Market Analysis

The key stakeholders in the global industrial brakes market ecosystem include raw material suppliers, industrial brakes manufacturers, and end-users. The rising demand for advanced brakes in manufacturing units across different industries is one of the prominent factors driving the demand for industrial brakes. The raw material suppliers offer several different units for various types of industrial brakes, such as mechanically applied brakes, hydraulically applied brakes, pneumatically applied brakes, and electrically applied brakes. In addition to this, the use of industrial brakes by end users for facilitating by offering the necessary velocity, acceleration, and deceleration to the industrial equipment is further influencing the demand for industrial brakes.

Industrial Brakes Market Overview

Industrial brakes are widely used in heavy machinery and industrial vehicles manufacturing such as excavators, bulldozers, backhoes, skid steers, and among others. Industrial brakes are also used in various food processing equipment, medical devices, hydraulic machines in industrial plants, automotive manufacturing and other applications. The industrial brakes market has the largest share in the Asia Pacific region owing to several small and medium-scale manufacturers followed by the leading players. Some of the industrial brake manufacturers across the Asia Pacific region include Altra Industrial Motion Corp., ADVICS CO., LTD.; Akebono Brake Industry Co., Ltd., AMETEK Inc., Eaton Corporation plc; Emco Precima Engineering Pvt Ltd. and among others. These manufacturers supply industrial brakes to various industries across the globe.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Industrial Brakes Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Industrial Brakes Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Industrial Brakes Market Drivers and Opportunities

Growth of the Global Manufacturing Sector

Since the beginning of the Industrial Revolution, technological advancements have led to tremendous surge in industrial production capacities; as a result, manufacturing is on the rise across the world. According to PricewaterhouseCoopers (PwC), growing economies, labor quality, tax policies, regulatory environments, and transportation and energy prices are the factors that have catalyzed the comeback of this sector. As a result of the expanding manufacturing sector, the dependent markets, including mechanical equipment providers, are also flourishing. With the emergence of new categories of consumers in developing countries, manufacturers across the world are likely to have significant new prospects; further, innovations generate new demands, thus propelling the use of modern equipment and systems in manufacturing units.

Stringent Rules and Regulations Related to Industrial Machinery

Machines are necessary for the production process, but mishaps during their operations can result in burns, blindness, and amputation. Safeguarding, standardizing operating procedures, and thorough training may assist in keeping the staff safe and secure. Governments and organizations across the world are transforming their operations by implementing emission and safety standards in production facilities. The Occupational Safety and Health Administration (OSHA) fines for the infraction of safety standards totaled more than US$ 50 million in the fiscal year 2018. As a result, the US government is developing a long-term regulatory road plan for the flourishment of the manufacturing sector, escalating its contribution to the GDP.

Developments in Industrial Braking Technology

When designing equipment systems, it's crucial to think about how the braking system will affect the operation of subsequent machines. Fail-safe brakes assist in shutting off the machine’s movement quickly in accidents, performance failures, or power failures, among others. Companies are also working on hydraulic release brakes that are spring-loaded braking systems using hydraulic energy to produce adjustable torque. The need for industrial brakes is high in mining winches, overhead cranes, steel rolling systems, and other similar devices. Furthermore, warehousing, medical, steel mills, and food processing industries hold significant potential for the industrial brakes market. Companies are actively working on spring-applied brakes with high permitted braking energies, high torques, and wear resistance. For instance, Kor-Pak, an OEM and distributor of industrial brakes and clutches, is developing end-to-end braking systems for the mining and manufacturing industries.

Industrial Brakes Market Report Segmentation Analysis

Key segments that contributed to the derivation of the industrial brakes market analysis are temperature type, warehouse type, and application.

- Based on type, the market is divided into mechanically applied brakes, hydraulically applied brakes, pneumatically applied brakes, electrically applied brakes, and others. Mechanically applied brakes apply force, most commonly friction, to slow or stop a machine or an object from moving. The force is applied to a body that is in rotational or linear motion, such as an axle, shaft, or wheel. Mechanical brakes are used in material handling, manufacturing, and other power transmission applications and are most commonly associated with automobiles. For engaging and disengaging shafts, mechanical brakes are frequently used in conjunction with a mechanical clutch. To decelerate, friction-based brakes use a coarse and tough substance (a brake lining) that is tightened or forced against a moving body. Friction-based braking creates a lot of heat and considerable noise, which degrades the involved surface areas.

- Based on application, the global industrial brakes market is divided into holding brakes, dynamic and emergency brakes, and tension brakes. Motor-holding brakes are responsible for maintaining the motor's position when the power stage is turned off. The holding brake is neither a safety feature nor a maintenance brake. This brake is used in factory automation, medical equipment, elevators and escalators, construction equipment, robotics, and machine tool equipment. Many companies offer holding brakes for various applications and industrial environments. For example, Vortex Engineering Works provides spring-holding brakes for operations in the textile industry.

- Depending upon the industry vertical, the market is divided into manufacturing, metal and mining, construction, power generation, marine and shipping, and others.

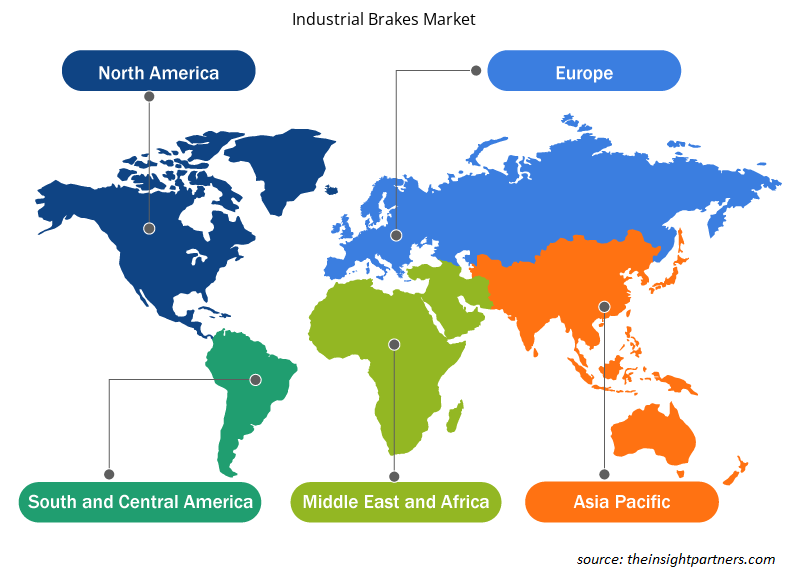

Industrial Brakes Market Share Analysis by Geography

The geographic scope of the Industrial Brakes market report is mainly divided into five regions: North America, APAC, Europe, Middle East & Africa, and SAM.

Persistent developments in the industrial sector in Asia Pacific countries add to their economic prosperity. This change has resulted in rising affluence, urbanization, and population expansion. Furthermore, Asia Pacific makes for a substantial portion of the global energy consumption, with the industrial sector accounting for the majority of the regional energy consumption. The region comprises 58 economies and is home to over 60% of the world's population. As per ADB Annual Report 2018, its share in the global purchasing power parity gross domestic product (GDP PPP) increased from 30.1% in 2000 to 42.6% in 2017, and three nations—China, Japan, and India—accounted for more than 70% of the region's total production in 2017. In 2014, the total energy consumption of Asia Pacific increased at double the pace of the world; it consumes more than 50% of the total energy supply of the world and accounts for ~55% of global fuel emissions.

The expansion of the industrial sector also results in higher energy consumption and greenhouse gas emissions. The use of energy-saving alternatives in enterprises that require optimal working conditions is increasing demand for various types of industrial brakes. Furthermore, increased energy security, improved workplace environmental quality, and new job creation with the introduction of business prospects related to energy efficiency have also led to the growth of industrialization in the region, thereby propelling the industrial brakes market growth.

Industrial Brakes Market Regional Insights

The regional trends and factors influencing the Industrial Brakes Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Industrial Brakes Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Industrial Brakes Market

Industrial Brakes Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2023 | US$ 1.30 Billion |

| Market Size by 2031 | US$ 2.05 Billion |

| Global CAGR (2023 - 2031) | 5.9% |

| Historical Data | 2021-2022 |

| Forecast period | 2023-2031 |

| Segments Covered |

By Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

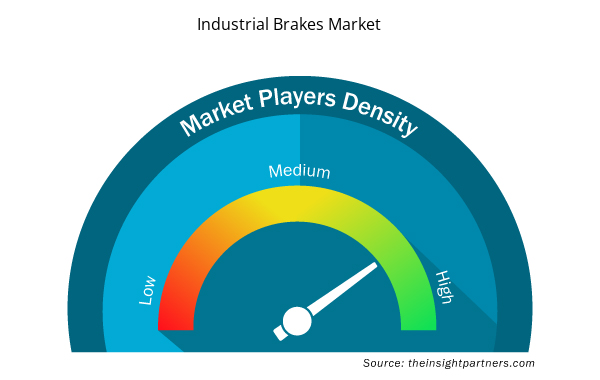

Industrial Brakes Market Players Density: Understanding Its Impact on Business Dynamics

The Industrial Brakes Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Industrial Brakes Market are:

- Akebono Brake Industry Co., Ltd.

- Altra Industrial Motion Corporation

- Ametek Inc.

- Aplicación Nuevas Tecnologías Antec SAU

- Dellner Bubenzer Germany GmbH

- Hilliard Corporation

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Industrial Brakes Market top key players overview

Industrial Brakes Market News and Recent Developments

The industrial brakes market is evaluated by gathering qualitative and quantitative data post primary and secondary research, which includes important corporate publications, association data, and databases. The following is a list of developments in the market for innovations, business expansion, and strategies:

- In March 2023, TVS Apache Brakes brand in India launched advanced technology-based ZAP brake pads for electric vehicles. ZAP is a braking fluid that was created and developed to meet the user’s requirement for electric vehicles. It improves corrosion resistance, provides protection, and offers silent braking for electric vehicles. (Source: Eurofins, Press Release)

Industrial Brakes Market Report Coverage and Deliverables

The “Industrial Brakes Market Size and Forecast (2021–2031)” report provides a detailed analysis of the market covering the following areas:

- Industrial Brakes Market size and forecast at global, regional, and country levels for all the key market segments covered under the scope

- Market dynamics such as drivers, restraints, and key opportunities

- Industrial Brakes Market Trends

- Detailed PEST Analysis and SWOT analysis

- Industrial Brakes Market Analysis covering key market trends, Global and regional framework, major players, regulations, and recent market developments.

- Industrial Brakes Market Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments.

- Detailed Company Profiles

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

- Smart Locks Market

- Customer Care BPO Market

- Sweet Potato Market

- Visualization and 3D Rendering Software Market

- Travel Vaccines Market

- Vision Care Market

- Emergency Department Information System (EDIS) Market

- Single-Use Negative Pressure Wound Therapy Devices Market

- Workwear Market

- Procedure Trays Market

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Type, Application, and Industry Vertical

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

Argentina, Australia, Brazil, Canada, China, France, Germany, India, Italy, Japan, Mexico, Russian Federation, Saudi Arabia, South Africa, South Korea, United Arab Emirates, United Kingdom, United States

Frequently Asked Questions

North America is expected to dominate the industrial brakes market in 2023.

The growth of the global manufacturing sector drives market growth.

Stringent rules and regulations related to industrial machinery driving the market trend.

Akebono Brake Industry Co., Ltd., Altra Industrial Motion Corporation, Ametek Inc., Aplicación Nuevas Tecnologías Antec SAU, Dellner Bubenzer Germany GmbH, Hilliard Corporation, Kobelt Manufacturing Co. Ltd., KOR-PAK Corporation, Ringspann GmbH and Tolomatic, Inc

Industrial brakes market size is projected to reach US$ 2.05 billion by 2031 from US$ 1.30 billion in 2023.

The market is expected to register a CAGR of 5.9% in 2023–2031.

Get Free Sample For

Get Free Sample For