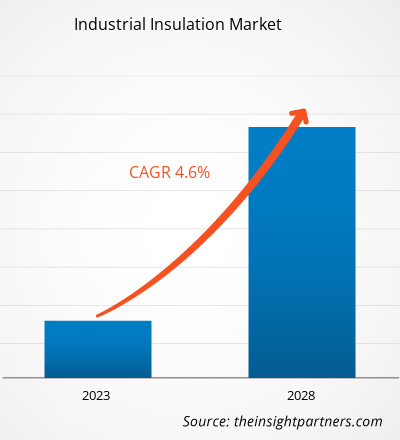

[Research Report] The industrial insulation market is expected to grow from US$ 7,793.91 million in 2022 to US$ 10,189.11 million by 2028; it is expected to grow at a CAGR of 4.6% from 2022 to 2028.

MARKET ANALYSIS

Industrial insulation plays an important role in various industries namely, power generation, chemical and petrochemical, cement, and food and beverages. Industrial insulation is highly important in various hydroelectric plants as it aids the steam-generating boilers in maintaining temperature levels. Further, increased infrastructural spending in emerging economies is expected to offer lucrative opportunities for the market growth during the forecast period. With the increase in construction activities in different countries across the globe, the demand for industrial insulation is increasing. Use of industrial insulation in infrastructure helps in protection from heat, fire, and corrosion.

GROWTH DRIVERS AND CHALLENGES

The strict regulation mandating the use of insulation material for energy conservation across the globe has aided the market growth of industrial insulation. Insulation materials provide resistance to heat flow and it also helps in lowering heating and cooling costs. Strict regulations for the mandatory use of insulation materials for energy saving purposes are the major factor boosting the growth of the industrial insulation market. Energy saving regulations and the need for insulation materials in end-use industries such as oil and gas, chemical and petrochemical, food and beverage are driving the market growth. Standards established by various associations namely, the American Society of Mechanical Engineers (ASME), American Boiler Manufacturers Association (ABMA), and American Society for Testing and Materials (ASTM) apply to the design of equipment in the industry, to implement safety protocols, thus boosting the growth of industrial insulation market. High installation cost for industrial insulation poses a challenge to the industrial insulation market. The cost of installation of industrial insulation can vary depending upon the type, design, size and complexity. Installation of industrial insulation is a complex process and requires advanced tools and operations. Further, a technically trained person is required in order to assess the size of facility, area of insulation and material of insulation. Moreover, installation of heavy insulation materials such as mineral wool, foam board and fiberglass require qualified professional, thus adding to the industrial installation cost.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Industrial Insulation Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Industrial Insulation Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

REPORT SEGMENTATION AND SCOPE

The "Global Industrial Insulation Market Analysis to 2030" is a specialized and in-depth study with a major focus on the global market trends and growth opportunities. The report aims to provide an overview of the global market with detailed market segmentation by raw material, product, end user, and geography. The global industrial insulation market has been witnessing high growth over the recent past and is expected to continue this trend during the forecast period. The report provides key statistics on the consumption of industrial insulation worldwide along with their demand in major regions and countries. In addition, the report provides the qualitative assessment of various factors affecting the industrial insulation market performance in major regions and countries. The report also includes a comprehensive analysis of the leading players in the industrial insulation market and their key strategic developments. Several analyses on the market dynamics are also included to help identify the key driving factors, market trends, and lucrative opportunities that would, in turn, aid in identifying the major revenue pockets.

Further, ecosystem analysis and Porter’s five forces analysis provide a 360-degree view of the global industrial insulation market, which helps understand the entire supply chain and various factors affecting the market growth.

SEGMENTAL ANALYSIS

The global industrial insulation market is segmented on the basis of raw material, product, and end user. Based on raw material, the industrial insulation market is segmented as wool, foams, and fibers and others. On the basis of product, the market is classified as, pipe, board, blanket, and others. The industrial insulation market is categorized on the basis of end user into, power generation, chemical and petrochemical, cement, food and beverage, and others. Based on raw material, the foams raw material accounted for a significant share. Wool insulation in the form of fiberglass is made by heating glass at high temperatures until it melts, and the molten glass is twisted quickly to create fibers. Glass wool fibers are then bound together to be used as insulation. Glass fibers create air pockets that act as barriers to heat loss as the air is a poor conductor of heat. Foam insulations are polymeric products widely used for various proofing and insulation end users, including thermal insulation, acoustic insulation, and weatherproofing. Fibers include natural and synthetic or plastic fibers. Ceramic fibers and recycled plastic bottles—composed of PET—are primarily used products for industrial insulation end users, and the fibers formed are pressed into batt insulation. Based on product, pipe segment accounted for a major share. Fiberglass is extensively used to insulate iron, copper, and PVC pipes in commercial, industrial, and institutional buildings due to its lower cost and easy installation. Industrial Insulation boards are commonly used to insulate cavity walls. Blanket insulation products are mostly used in high-temperature set-ups, with operating temperatures up to 1150°C. Typical end users of blanket insulation include heat exchangers, stack installations, cooling towers, air conditioning ductwork, large diameter piping, and storage tanks. Other products include spray foam insulation and insulating concrete. Spray foam insulation is an air barrier and insulation material that seals floors, walls, and ceiling cavities against air movement. Power generation is the major market for industrial insulation. Proper equipment insulation helps with the maintenance of power plants that reduces the risk of injury or burns to workers. Chemical processing needs stable temperatures to keep production quality consistent and reliable. The growth in the chemical & petrochemical industry is projected to fuel the demand for industrial insulation products. Cement manufacturing is a continuous process industry that requires advanced thermal solutions to optimize its output. The others segment is further segmented into automotive, aerospace, glass production, etc. Industrial Insulation solutions are used to help protect vehicle components and their electrical wiring.

REGIONAL ANALYSIS

The report provides a detailed overview of the global industrial insulation market with respect to five major regions, namely; North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South & Central America. Asia Pacific accounted for a significant share of the market and valued at more than US$ 4,000.00 million in 2022. Most countries in Asia Pacific are expected to witness continued growth in electricity demand, thus expected to fuel the demand for industrial insulation products in the region during the forecast period. North America is also expected to witness considerable growth valued at approximately US$ 1600.00 million in 2028, attributed to the growing adoption of expansion strategies by the end-use industries that need lignosulfonate-based concrete admixture in order to fulfil the rising demand for non-corrosive water-reducing admixtures in the construction industry. Europe is growing considerably with CAGR with more than 4.0%. The strong presence of chemical manufacturing bases and the aerospace industry in different countries bolsters the industrial insulation market in the Europe.

INDUSTRY DEVELOPMENTS AND FUTURE OPPORTUNITIES

The report provides a detailed overview of the global industrial insulation market with respect to five major regions, namely; North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South & Central America.

In 2022, Saint-Gobain planned to invest €120 million in new glass wool production capacity in France. The investment is aimed to increase the insulation production capacity in France. It includes increasing production of existing ISOVER production line and creating a new line.

In 2020, Johns Manville announced the launch of a complete portfolio of water-repellent mineral wool products for industrial insulation market. The product launch was aimed meet the growing demand for water-repellent materials in industrial insulation market.

IMPACT OF COVID/IMPACT OF GEOPOLITICAL SCENARIO/IMPACT OF RECESSION

The report provides a detailed overview of the global industrial insulation market with respect to five major regions, namely; North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South & Central America. Industries such as construction, chemicals and petrochemical, and food and beverages, have been the major consumers of industrial insulation. In 2020, these industries had to slow down their operations due to disruptions in the value chain caused by the shutdown of national and international boundaries. Moreover, lockdowns imposed by different countries hampered the ability of industries to maintain inventory levels in the same year. The pandemic also wreaked havoc on the chemicals as well as construction industry. The shortage of manpower resulted in the deceleration of industrial insulation production and distribution operations. Additionally, government restrictions and other COVID-19 precautions reduced the production capacities of industrial insulation manufacturers in the value chain. In 2021, the global marketplace began recovering from the losses incurred in 2020 as governments of different countries announced relaxations in social restrictions. Further, expanding production capacities in the chemicals & materials industry in different regions of the world resulted in a rise in demand for industrial insulation in 2021.

Industrial Insulation Market Regional Insights

Industrial Insulation Market Regional Insights

The regional trends and factors influencing the Industrial Insulation Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Industrial Insulation Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Industrial Insulation Market

Industrial Insulation Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2022 | US$ 7.79 Billion |

| Market Size by 2028 | US$ 10.19 Billion |

| Global CAGR (2022 - 2028) | 4.6% |

| Historical Data | 2020-2021 |

| Forecast period | 2023-2028 |

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

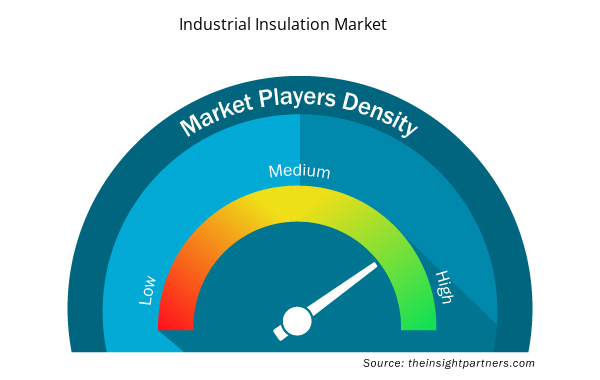

Industrial Insulation Market Players Density: Understanding Its Impact on Business Dynamics

The Industrial Insulation Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Industrial Insulation Market are:

- Nichias Corporation

- Aspen Aerogels Inc.

- McAllister Mills Inc.

- ROCKWOOL A/S

- SAINT GOBAIN S.A.

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Industrial Insulation Market top key players overview

COMPETITIVE LANDSCAPE AND KEY COMPANIES

Some of the key players operating in the industrial insulation market include, Nichias Corporation, Aspen Aerogels Inc, McAllister Mills Inc, Rockwool A/S, Saint Gobain SA, Knauf Insulation, Kingspan Group, Cabot Corporation, Johns Manville, and Thomas Group, among others.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

- Nuclear Waste Management System Market

- Nitrogenous Fertilizer Market

- Industrial Inkjet Printers Market

- Thermal Energy Storage Market

- Bioremediation Technology and Services Market

- Dried Blueberry Market

- Excimer & Femtosecond Ophthalmic Lasers Market

- Mobile Phone Insurance Market

- Micro-Surgical Robot Market

- Parking Management Market

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Raw Material, Product, and End User

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

Argentina, Australia, Brazil, Canada, China, France, Germany, India, Italy, Japan, Mexico, Russian Federation, Saudi Arabia, South Africa, South Korea, United Arab Emirates, United Kingdom, United States

Frequently Asked Questions

The global industrial insulation market is primarily driven by increasing demand from power generation sector and strict regulation mandating the use of insulation materials for energy conservation.

Major players operating in the global industrial insulation market includes, Nichias Corporation, Aspen Aerogels Inc., McAllister Mills Inc., ROCKWOOL A/S, SAINT GOBAIN S.A., Knauf Insulation, Kingspan Group, CABOT CORPORATION, Johns Manville, and Thomas Group.

The pipe segment held the largest share of the global industrial insulation market in 2021. Pipe insulation helps to reduces energy losses to a great extent, hence reducing the energy cost. Cellular glass, one of the types of materials used in pipe insulation, is used in ductwork, heat transfer fluid systems, chemical processing systems, commercial pipework, storage tanks, and other application areas.

In 2021, Asia Pacific held the largest share of the global industrial insulation market. The industrial insulation market growth in the region is driven by increasing demand from various industries, including power generation, chemical & petrochemical, and food & beverage, the growing industrial activities, and strong economic growth in the region.

Asia Pacific is estimated to register the fastest CAGR in the global industrial insulation market over the forecast period. This is mainly attributed to an increasing use of industrial insulation materials in different application fields, increasing infrastructural spending, and strong economic growth.

The foams segment held the largest share of the global industrial insulation market in 2021. Foam insulations are commonly used for various proofing and insulation applications, including thermal insulation, acoustic insulation, and weatherproofing.

Trends and growth analysis reports related to Chemicals and Materials : READ MORE..

The List of Companies - Industrial Insulation Market

- Nichias Corporation

- Aspen Aerogels Inc.

- McAllister Mills Inc.

- ROCKWOOL A/S

- SAINT GOBAIN S.A.

- Knauf Insulation

- Kingspan Group

- CABOT CORPORATION

- Johns Manville

- Thomas Group

Get Free Sample For

Get Free Sample For