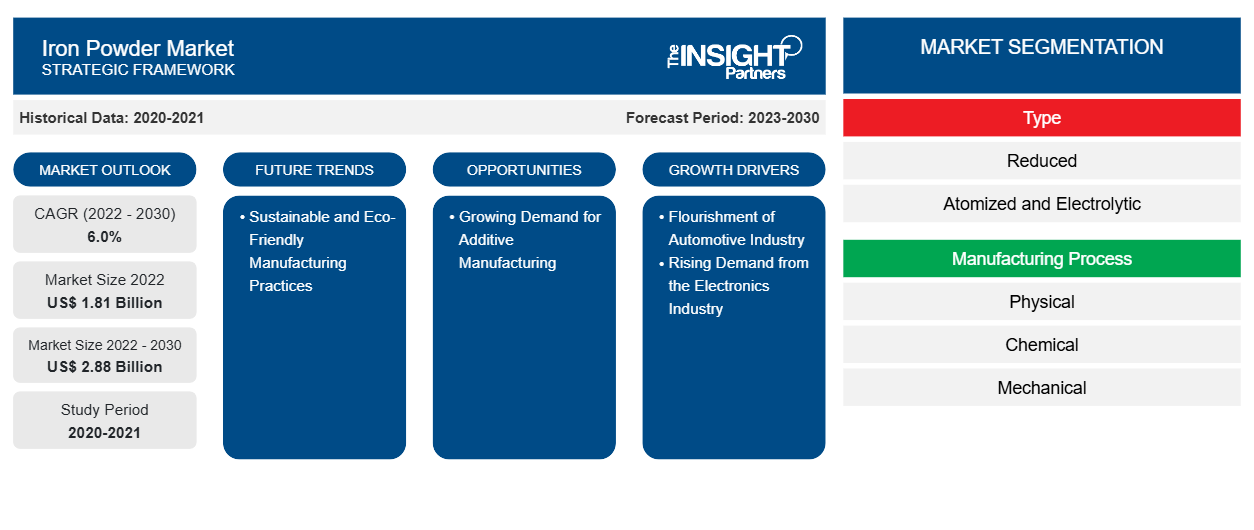

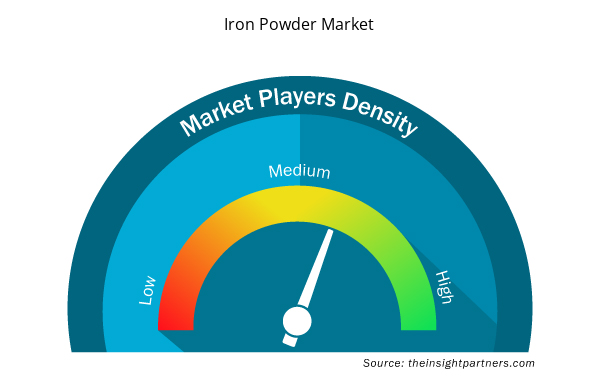

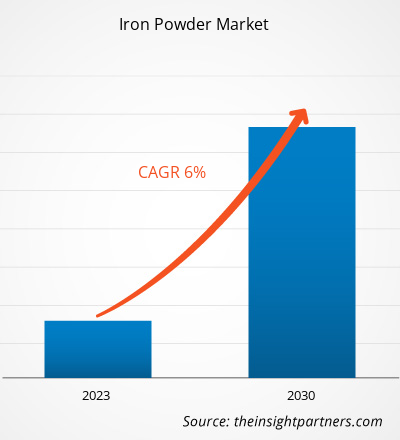

[Research Report] The iron powder market size was valued at US$ 1,806.32 million in 2022 and is expected to reach US$ 2,880.31 million by 2030; it is estimated to register a CAGR of 6.0% from 2022 to 2030.

Market Insights and Analyst View:

Iron powder is a finely ground form of iron that consists of tiny, individual particles of the metal. This substance is created by reducing iron oxide, typically in the form of iron ore or rust, using a process that involves heating and sometimes the use of carbon or hydrogen as reducing agents. The resulting iron powder is usually gray to black and is known for its high reactivity due to its small particle size. It finds a wide range of applications in various industries. Iron powder is widely used in manufacturing iron-based products such as ferrous alloys and steel. It is often mixed with other metals or materials to create custom alloys with specific properties, such as increased strength or corrosion resistance. Iron powder is also used to produce sintered components, which are compacted and heated to create parts for industries such as automotive manufacturing. The automotive industry heavily relies on iron powder as it is a fundamental raw material in the field of powder metallurgy. This manufacturing process involves shaping and sintering metal powders to create intricate parts. Automotive manufacturers increasingly turn to powder metallurgy for the production of components such as gears, bearings, and bushings, as it offers cost-effective, precise, and resource-efficient manufacturing solutions. In addition, in recent years, the automotive sector has heavily invested in reducing the weight of vehicles to enhance fuel efficiency and reduce emissions. Iron powder, when integrated into metal matrix composites and other advanced materials, can contribute to the development of lightweight components that maintain structural integrity. All these factors contribute to the iron powder market growth.

Growth Drivers and Challenges:

The iron powder market has experienced significant growth, primarily driven by rising demand from the electronics industry. The electronics industry relies heavily on powdered iron for various applications, such as manufacturing inductors and transformers. These components are essential for the functioning of electronic devices, including smartphones, computers, and power supplies. As consumer electronics continue to advance and become readily available, the demand for high-quality iron powder rises. Additionally, the trend toward miniaturization in the electronics industry has created a need for smaller, more efficient components. Iron powder is well-suited for this purpose, as it can be finely tuned to meet specific requirements, such as magnetic properties and particle size distribution. This versatility has made iron powder attractive for manufacturers producing compact, high-performance electronic devices. In addition, the push for renewable energy sources and electric vehicles has further boosted the demand for iron powder. Electric motors and generators used in these technologies often rely on iron powder cores for their magnetic properties, enhancing efficiency and reducing energy loss.

As electronic devices become more advanced and interconnected, they generate higher levels of electromagnetic radiation. This radiation can interfere with the proper functioning of nearby electronic components, leading to reduced performance and reliability. All these factors led to the iron powder market growth.

However, volatile raw material prices pose significant constraints on the growth of the iron powder market. This volatility primarily stems from fluctuations in the prices of essential inputs such as iron ore and energy sources, and it reverberates throughout the industry, impacting multiple facets of its operations. Iron powder manufacturers heavily rely on stable cost structures to plan their production processes effectively. However, when the prices of raw materials change unpredictably, it becomes exceedingly challenging to estimate production costs accurately. Consequently, manufacturers are forced to operate with high uncertainty, which can lead to reduced profit margins and financial instability. The impact extends beyond cost considerations. Volatile raw material prices can also disrupt the iron powder market growth trajectory by affecting investment decisions. Companies may be hesitant to invest in expanding their production capacity or developing new technologies when the cost of raw materials remains unpredictable. This hesitance can restrict innovation and limit the industry's ability to meet growing demand. These factors could limit the iron powder market growth.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Iron Powder Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Iron Powder Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Report Segmentation and Scope:

The "Iron Powder Market Analysis to 2030" is a specialized and in-depth study with a major focus on the global iron powder market trends and growth opportunities across the globe. The report aims to provide an overview of the iron powder market with detailed market segmentation by application and end-use. The global iron powder market has witnessed high growth in the recent past and is expected to continue this trend during the forecast period. The report provides key statistics on the consumption of iron powder across the globe. In addition, the report provides a qualitative assessment of various factors affecting the iron powder market performance across the globe. The report also includes a comprehensive analysis of the leading players in the global iron powder market and their key strategic developments. Several analyses on the market dynamics are also included to help identify the key driving factors, market trends, and lucrative opportunities that would, in turn, aid in identifying the major revenue pockets.

Further, ecosystem analysis and Porter's five forces analysis provide a 360-degree view of the global iron powder market, which helps understand the entire supply chain and various factors affecting the market growth.

Segmental Analysis:

The global iron powder market is segmented on the basis of type, manufacturing process, grade, end-use industry, and geography. Based on type, the market is categorized into reduced, atomized, and electrolytic. In terms of manufacturing process, the market is segmented into physical [atomization and electro deposition], chemical [reduction and decomposition], and mechanical. On the basis of grade, the market is bifurcated into ≤ 99.0% and ≥ 99.1%. In terms of the end-use industry, the market is segmented into paints & coatings, additive manufacturing, medical, soft magnetic products, metallurgy [compound brazing, compound sintering, compound welding, and others], and others. The additive manufacturing segment is expected to register significant growth from 2022 to 2030. Iron powder is a crucial material in the realm of additive manufacturing, also known as 3D printing, due to its versatile applications and excellent properties. This finely powdered form of iron is employed in various additive manufacturing processes, such as powder bed fusion and binder jetting, to create intricate and durable metal components. The significant usage of iron powder in additive manufacturing is in the production of high-strength and lightweight parts for industries such as aerospace and automotive. Iron-based alloys, such as stainless steel or tool steel, can be synthesized by mixing iron powder with alloying elements, and the resulting components exhibit exceptional mechanical properties, corrosion resistance, and heat resistance.

Iron powder's magnetic properties make it indispensable in manufacturing electromagnetic components and sensors, where precise geometries are essential. Its ability to be easily sintered or fused during the additive manufacturing process enables the creation of complex, customized magnetic devices with precision. All these factors are driving the growth of the additive manufacturing segment, subsequently boosting the iron powder market growth.

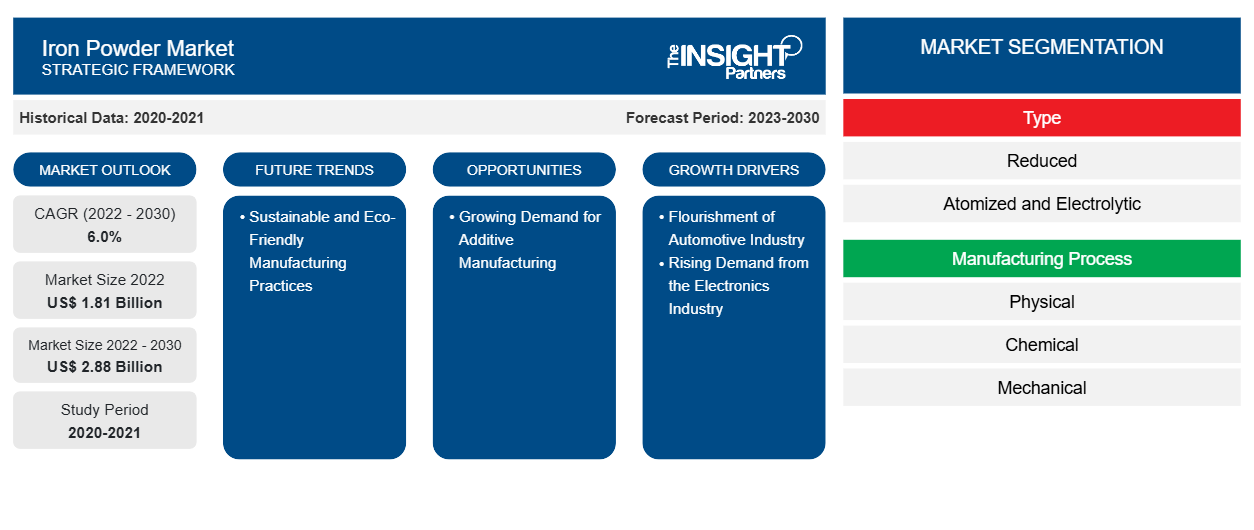

Regional Analysis:

Based on geography, the iron powder market is segmented into five key regions—North America, Europe, Asia Pacific, South & Central America, and the Middle East & Africa. The market was dominated by Asia Pacific, which accounted for ~US$ 700 million in 2022. The region encompasses an ample number of opportunities for the growth of iron powder. Rising foreign direct investments also lead to economic growth in the region. The growing use of iron powders in numerous applications, including metallurgy, coating and decorations, electronic materials, sintered parts, diamond cutting tools, and others, is anticipated to surge the iron powder demand in Asia Pacific.

The increasing projects in the field of electrification, coupled with the growth of the electronics industry in the Asia Pacific, are expected to boost the iron powder market growth in Asia Pacific during 2022–2030. Europe is expected to register a CAGR of over 6.0% from 2022 to 2030. The demand for iron powder in Europe has been experiencing notable growth due to the European Union's commitment to sustainability and environmental goals. Iron powder is considered an eco-friendly alternative to traditional materials in various applications. All these factors are driving the iron powder market growth in Europe. Further, North America is expected to reach US$ 600 in 2030. With many automakers transitioning to EV production, the demand for iron powder has surged, as it is a crucial component in electric motor manufacturing and battery technology. For instance, Tesla's expansion of its Gigafactories in the US has resulted in a substantial uptick in the consumption of iron powder, reflecting the robust growth of the EV market in the region, further driving the iron powder market growth.

Industry Developments and Future Opportunities:

Various initiatives taken by the key players operating in the iron powder market are listed below:

- In May 2023, Jiangxi Yuean Advanced Materials Co. Ltd began the construction of a new Carbonyl Iron Powder (CIP) production line. The new CIP unit will have a production capacity of 6,000 metric ton per year.

Iron Powder Market Regional Insights

Iron Powder Market Regional Insights

The regional trends and factors influencing the Iron Powder Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Iron Powder Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Iron Powder Market

Iron Powder Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2022 | US$ 1.81 Billion |

| Market Size by 2030 | US$ 2.88 Billion |

| Global CAGR (2022 - 2030) | 6.0% |

| Historical Data | 2020-2021 |

| Forecast period | 2023-2030 |

| Segments Covered |

By Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

Iron Powder Market Players Density: Understanding Its Impact on Business Dynamics

The Iron Powder Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Iron Powder Market are:

- SK Rio Tinto Metal Powders

- American Elements Inc

- Industrial Metal Powders (INDIA) Pvt Ltd

- CNPC Powder North America Inc

- Ashland Inc

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Iron Powder Market top key players overview

COVID-19 Impact:

The COVID-19 pandemic adversely affected almost all industries in various countries. Lockdowns, travel restrictions, and business shutdowns in North America, Europe, Asia Pacific (APAC), South & Central America, and the Middle East & Africa (MEA) hampered the growth of several industries, including the chemical & materials industry. The shutdown of manufacturing units of iron powder companies disturbed global supply chains, manufacturing activities, and delivery schedules. Various companies reported delays in product deliveries and a slump in their product sales in 2020. Most of the industrial manufacturing facilities were shut down during the pandemic, decreasing the consumption of iron powder. In addition, the COVID-19 pandemic has caused fluctuations in iron powder prices. However, various industries revived their operations after supply constraints were resolved, which led to a revival of the market. Moreover, the rising demand for iron powder from the paints & coatings, additive manufacturing, and medical sectors is substantially promoting the iron powder market growth.

Competitive Landscape and Key Companies:

Rio Tinto Metal Powders, American Elements Inc, Industrial Metal Powders (India) Pvt Ltd, CNPC Powder North America Inc, Ashland Inc, BASF SE, Hoganas AB, JFE Steel Corp, Reade International Corp, and Kobe Steel Ltd are among the players operating in the global iron powder market. The market players focus on providing high-quality products to fulfill customer demand.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Type, Manufacturing Process, Grade, and End-Use Industry

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

This text is related

to country scope.

Frequently Asked Questions

The growing demand for additive manufacturing, also known as 3D printing, presents significant growth opportunities for the iron powder market. This transformative technology is revolutionizing industries across the globe, and iron powder is emerging as a key material to meet the unique requirements of 3D printing applications. Additive manufacturing is experiencing widespread adoption across various sectors, including aerospace, automotive, and healthcare. This adoption is driven by the ability of 3D printing to produce complex and customized parts with precision and efficiency.

Based on type, the iron powder market is segmented into reduced, atomized, and electrolytic. The atomized segment held the largest market share in 2022. Atomized iron powder is produced using a specialized atomization process. In this process, molten iron is subjected to high-pressure gas or water jets, causing it to break up into fine droplets or particles. These droplets rapidly solidify into small, spherical, or irregularly shaped powder particles as they cool down.

The major players operating in the global iron powder market are Rio Tinto Metal Powders, American Elements Inc, Industrial Metal Powders (INDIA) Pvt Ltd, CNPC Powder North America Inc, Ashland Inc, BASF SE, Hoganas AB, JFE Steel Corp, Reade International Corp, Kobe Steel Ltd.

The automotive industry heavily relies on iron powder as it is a fundamental raw material in the field of powder metallurgy. This manufacturing process involves shaping and sintering metal powders to create intricate parts. Automotive manufacturers increasingly turn to powder metallurgy for the production of components such as gears, bearings, and bushings, as it offers cost-effective, precise, and resource-efficient manufacturing solutions.

Asia Pacific accounted for the largest share of the global iron powder market. Asia Pacific is one of the most significant regions for the iron powder market owing to drastic increase in the demand for passenger vehicles.

Based on application, the iron powder market is segmented into paints and coatings, additive manufacturing, medical, soft magnetic products, metallurgy and other. The iron powder market share of the additive manufacturing segment was notable in 2022. Iron powder is a crucial material in the realm of additive manufacturing, also known as 3D printing, due to its versatile applications and excellent properties. This finely powdered form of iron is employed in various additive manufacturing processes, such as powder bed fusion and binder jetting, to create intricate and durable metal components.

Trends and growth analysis reports related to Chemicals and Materials : READ MORE..

The List of Companies - Iron Powder Market

- SK Rio Tinto Metal Powders

- American Elements Inc

- Industrial Metal Powders (INDIA) Pvt Ltd

- CNPC Powder North America Inc

- Ashland Inc

- BASF SE

- Hoganas AB

- JFE Steel Corp

- Reade International Corp

- Kobe Steel Ltd

Get Free Sample For

Get Free Sample For