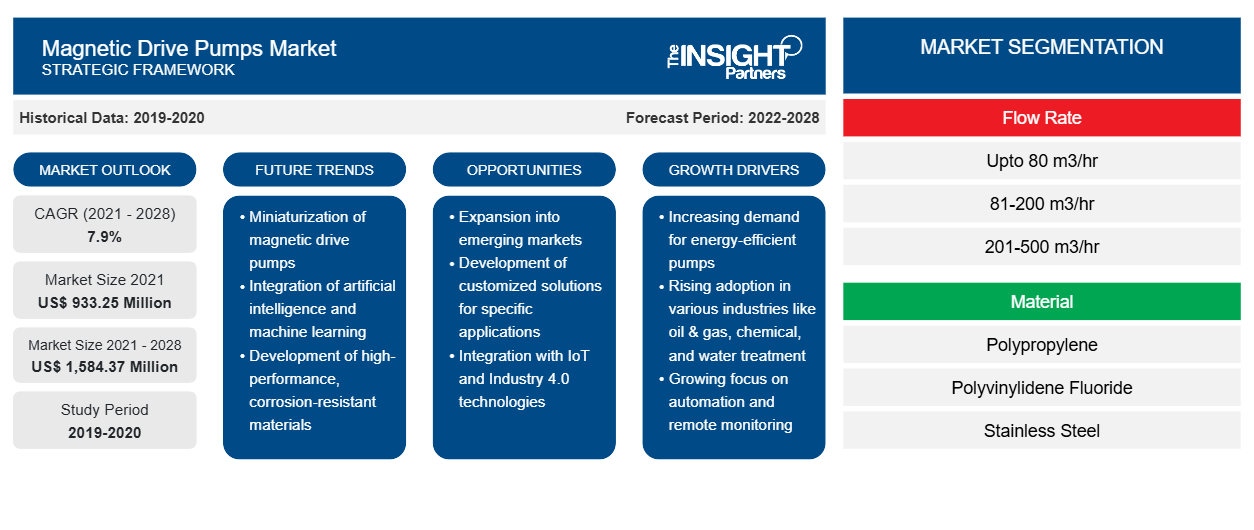

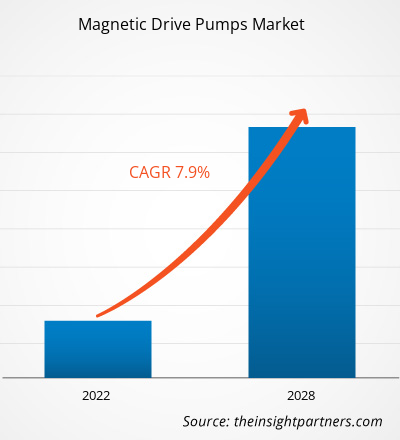

[Research Report] The magnetic drive pumps market is expected to grow from US$ 933.25 million in 2021 to US$ 1,584.37 million by 2028; it is estimated to grow at a CAGR of 7.9% during 2021–2028.

Analyst Perspective:

The magnetic drive pump market is a rapidly growing sector within the global pump industry. Magnetic drive pumps, also known as mag-drive pumps or magnetically coupled pumps, are designed to eliminate the need for traditional mechanical seals by utilizing a magnetic coupling to transfer torque from the motor to the impeller. This technology provides several advantages, including leak-free operation, reduced maintenance requirements, and enhanced safety. The market for magnetic drive pumps has witnessed significant growth in recent years, driven by various factors. One of the key drivers is the rising demand for seal-less pumping solutions across industries such as chemical processing, pharmaceuticals, water treatment, and oil and gas. The ability of magnetic drive pumps to eliminate leakage and reduce the risk of hazardous material exposure makes them highly desirable in these applications. Furthermore, stringent environmental regulations and a growing emphasis on operational efficiency have fueled the adoption of magnetic drive pumps. The elimination of leakage not only reduces product loss but also minimizes the impact on the environment. Additionally, magnetic drive pumps offer improved energy efficiency compared to traditional pumps, contributing to cost savings and sustainability.

The magnetic drive pump market is characterized by various magnetic drive pump types, including centrifugal, turbine, and gear pumps, each suitable for specific applications and requirements. Centrifugal magnetic drive pumps are the most commonly used type, offering high flow rates and moderate pressure capabilities. Turbine magnetic drive pumps are suitable for low-flow, high-pressure applications, while gear magnetic drive pumps are ideal for handling viscous fluids.

Market Overview:

Magnetic drive pumps move fluid through a pump by employing a drive magnet and an inner magnet connected to an impeller. The drive magnet and the inner magnet are separated by a rear casing and housing, resulting in sealless confinement. Using a magnetic drive pump can prevent fluid leaks and, more importantly, the loss of potentially dangerous and expensive substances. Pumps without seals have no fugitive emissions, which enables them to comply with all regulations. With increased environmental awareness and stricter EPA regulations, sealless pumps may comply with all requirements because they produce no fugitive emissions.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Magnetic Drive Pumps Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Magnetic Drive Pumps Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Market Driver:

Increase in The Use of Water Treatment for Water Treatment Projects to Drive Growth of Magnetic Drive Pumps Market

The increase in the use of water treatment for water treatment projects is a significant driver for the magnetic drive pump market. Water treatment plays a crucial role in purifying and ensuring the availability of clean water for various applications, including drinking water, industrial processes, and agricultural irrigation. As the demand for clean water rises, the need for effective and efficient water treatment solutions becomes increasingly critical. Magnetic drive pumps find extensive application in water treatment processes due to their seal-less design and ability to handle corrosive and hazardous fluids. These pumps are well-suited for handling chemicals, acids, and other aggressive substances commonly used in water treatment operations. The absence of mechanical seals eliminates the risk of leakage and contamination, ensuring the integrity of the treated water. Water treatment projects encompass various applications, including municipal water treatment plants, industrial wastewater treatment facilities, desalination plants, and groundwater remediation projects. In these applications, magnetic drive pumps are vital in pumping and circulating water through various treatment stages, such as filtration, disinfection, chemical dosing, and sludge handling.

The growing emphasis on environmental regulations and water quality standards further drives the adoption of magnetic drive pumps in water treatment projects. Stringent regulations require reliable and leak-free pumping systems to prevent the release of pollutants into water bodies. Magnetic drive pumps provide a dependable solution by eliminating the potential for leaks and ensuring the protection of the environment. Moreover, magnetic drive pumps' efficiency and operational advantages make them an attractive choice for water treatment projects. These pumps exhibit high energy efficiency, which helps reduce operational costs and minimize the environmental impact. Additionally, the absence of mechanical seals translates into reduced maintenance requirements, saving time and resources for water treatment operators.

Segmental Analysis:

On the basis of material, the market is categorized into polypropylene, polyvinylidene fluoride, stainless steel, nickel alloys, PFA, and ETFE. The stainless steel segment held the largest share of the magnetic drive pumps market in 2020, whereas the nickel alloys segment is anticipated to register the highest CAGR in the market during the forecast period. The chemical processing segment holds the largest share of the magnetic drive pump market. Magnetic drive pumps are widely utilized in chemical processing because they handle corrosive fluids and prevent leakage. The industry's focus on safety, environmental regulations, and operational efficiency drives the adoption of magnetic drive pumps. These pumps offer leak-free operation, ensuring the integrity of hazardous materials and reducing product loss. They also provide energy efficiency, lower maintenance requirements, and support process optimization. As the chemical industry expands, magnetic drive pumps will remain crucial in meeting its pumping needs.

Regional Analysis:

The Asia Pacific magnetic drive pumps market was valued at US$ 0.31 billion in 2021 and is projected to reach US$ 0.58 billion by 2028; it is expected to grow at a CAGR of 9.3% during the forecast period. The Asia Pacific region has emerged as the dominant magnetic drive pump market, exhibiting substantial growth and significant industry share. The region's dominance can be attributed to several key factors contributing to its market leadership. The Asia Pacific region has experienced rapid industrialization and economic growth over the past few decades. This has increased demand for various industrial processes, including chemical manufacturing, pharmaceutical production, water treatment, and more. The need for reliable and efficient pumping solutions in these industries has led to a significant uptake of magnetic drive pumps. The region's large population and rising urbanization have driven the demand for improved infrastructure, including water and wastewater treatment facilities. Magnetic drive pumps play a vital role in these projects, ensuring efficient and safe handling of fluids in diverse applications. The region's focus on sustainable development and compliance with environmental regulations has further boosted the adoption of magnetic drive pumps in water treatment processes.

The Asia Pacific region has numerous manufacturing hubs, particularly in countries such as China, India, and South Korea. These countries have a robust presence in industries such as chemicals, petrochemicals, and electronics, which are major consumers of magnetic drive pumps. These countries' local production capabilities and cost advantages have fueled the market's growth. Advancements in technology and increasing investments in research and development have played a crucial role in the region's market dominance. Manufacturers in the Asia Pacific region have been at the forefront of developing innovative magnetic drive pump solutions that cater to specific industry needs. This has further bolstered their competitiveness and contributed to the region's strong market position.

Key Player Analysis:

The magnetic drive pumps market analysis consists of the players such as IWAKI CO., LTD.; Sundyne; Klaus Union GmbH & Co. KG; Flowserve Corporation; Dickow Pump Company; KSB SE & Co. KGaA; ITT Goulds Pumps; Sulzer Ltd; Finish Thompson, Inc.; OPTIMEX; HERMETIC-Pumpen GmbH; CP Pumpen AG; and CDR Pumps. Among the players in the magnetic drive pumps Sulzer Ltd and Klaus Union GmbH & Co. KG are among the top players owing to the diversified product portfolio offered.

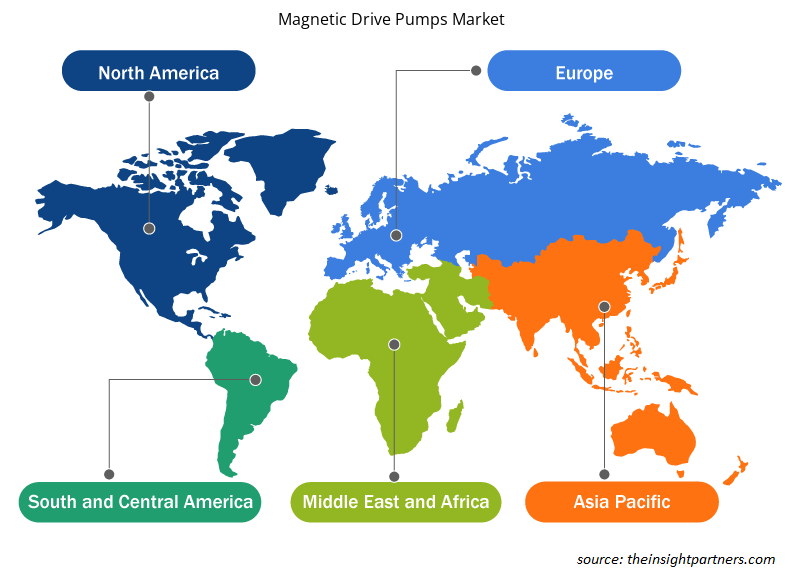

Magnetic Drive Pumps Market Regional Insights

The regional trends and factors influencing the Magnetic Drive Pumps Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Magnetic Drive Pumps Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Magnetic Drive Pumps Market

Magnetic Drive Pumps Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2021 | US$ 933.25 Million |

| Market Size by 2028 | US$ 1,584.37 Million |

| Global CAGR (2021 - 2028) | 7.9% |

| Historical Data | 2019-2020 |

| Forecast period | 2022-2028 |

| Segments Covered |

By Flow Rate

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

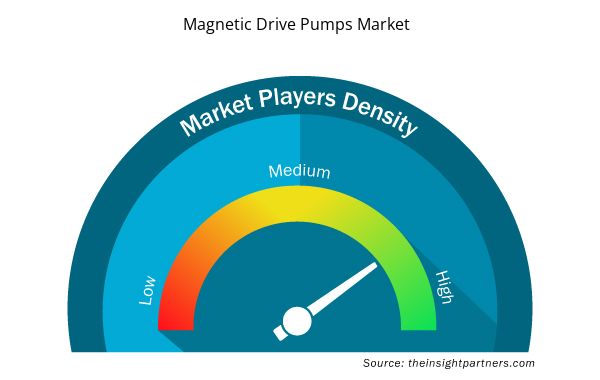

Magnetic Drive Pumps Market Players Density: Understanding Its Impact on Business Dynamics

The Magnetic Drive Pumps Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Magnetic Drive Pumps Market are:

- Flowserve Corporation

- Sulzer Ltd

- KSB SE & Co. KGaA

- Sundyne

- Klaus Union

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Magnetic Drive Pumps Market top key players overview

Recent Developments:

Inorganic and organic strategies such as mergers and acquisitions are highly adopted by companies in the magnetic drive pumps market. A few recent key market developments are listed below:

- In January 2021, Flowserve Corporation, a global leading provider of flow control products and services, launched an IoT service suite to enable remote monitoring of production facilities including pumps of all kind, predict equipment failures and avoid business disruptions.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Flow Rate, Material, Application, and Pump Type

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

Algeria, Angola, Argentina, Australia, Brazil, Bulgaria, Canada, China, Congo, Denmark, Egypt, France, Germany, Hungary, India, Italy, Japan, Mexico, Morocco, Nigeria, Poland, Romania, Russian Federation, Saudi Arabia, South Africa, South Korea, Sweden, Tunisia, Turkey, United Arab Emirates, United Kingdom, United States

Frequently Asked Questions

The use of magnetic drive pumps has increased in the renewable energy sector for the last few years. Biodiesel is a kind of liquid fuel produced from renewable sources like new and used vegetable oils and animal fats. Biodiesel is a much cleaner-burning replacement for various petroleum-based fuels. This is the reason for the growing demand for petroleum in various parts of the world. Magnetic drive pumps are designed and manufactured for optimum application in biodiesel production. These pumps are highly recommended for chemical transfer and chemical recirculation.

On the basis of material, the magnetic drive pumps market is segmented into polypropylene, polyvinylidene fluoride, stainless steel, nickel alloys, PFA, and ETFE. The stainless steel segment has the largest market share because the stainless steel pumps are mostly used due to its wide range of benefits including reduced initial cost of the pump, coupled with low operational cost with better quality. And major key players prefer stainless steel as casing material for magnetic drive pumps, including Magnatex Pumps, Inc.; Sichuan Zigong Pump & Valve Co., Ltd.; and March Manufacturing, Inc. Further, the nickel alloys segment has the faster growth rate due to growing adoption of magnetic drive pumps in chemical industry, petrochemical industry, refrigeration & heat transfer, oil & gas, power, and on/offshore plants.

Magnetic drive pumps are generally costlier compared to mechanical seal pumps. However, the maintenance costs are very low during the pump's service life, and such kind of long-term financial advantages are considered by end users while choosing the pump. The primary reason for lesser maintenance is the relatively simple design. Generally, when utilized for normal operations, it is normally seen that the magnetic drive pumps function for ten years or longer before requiring any kind of repair. Even when needed, the repairs are quite inexpensive. Magnetic drive pumps are manufactured to be driven by the force of magnets. Owing to this, the magnetic drive pumps do not have any shaft coming out of the pump casing, and there is no requirement for shaft sealing devices such as mechanical seals and gland packing.

On the basis of application, the magnetic drive pumps market is segmented into chemical processing, water treatment, surface treatment, food processing, oil and gas, and renewable energies. The chemical processing segment has the largest market share because the chemical pumps are widely required by several industries for transferring hazardous/dangerous fluids, ultra-pure liquids, and hard-to-seal liquids. Further, the water treatment segment has the faster growth rate due to the rising water treatment projects such as wastewater treatment in emerging economies such as North America, Europe, and Asia Pacific regions. The need of wastewater treatment is due to the growing population, urbanization, improving manufacturing activity, and rising oil & gas production.

In APAC, the magnetic drive pumps market is growing due to the increasing large-scale industrialization and urbanization. Countries such as China, South Korea, and Thailand have discovered new oil & gas reserves. Further, China and India have a greater number of chemical industries. Hence, the consumption of magnetic drive pumps is increasing with the growth of industries in the region. Another reason behind strong growth of magnetic drive pumps market over the years is the presence of large number of market players in the regions. Some of the key players in the APAC magnetic drive pumps market include; Kirloskar Brothers Limited (India), TEIKOKU ELECTRIC MFG. CO., LTD. (Japan), NIKKISO EIKO Co., Ltd. (Japan), and Zhejiang Yonjou Technology Co., Ltd (China), among others.

The environmental and safety impact of the respective fluid handling solutions is considered a top agenda while buying, using, and maintaining new pumps. Magnetic drive pumps are still firmly adopted for corrosive chemical applications. These pumps are characterized by enhanced corrosion resistance and dry running capabilities in the most severe conditions. Green technology is creating considerable demand for magnetic drive pumps in the methods of biodiesel fuels production, where mixtures of solvents and caustics create difficulties in sealing. Magnetic drive pumps help prevent fugitive emissions like volatile hazardous air pollutants (VHAPs) and volatile organic compounds (VOCs). Thus, using a magnetic drive pump helps the companies to stay compliant with the new state, local, and federal safety and health standards and regulations and avoid expensive fines.

Trends and growth analysis reports related to Manufacturing and Construction : READ MORE..

The List of Companies - Magnetic Drive Pumps Market

- Flowserve Corporation

- Sulzer Ltd

- KSB SE & Co. KGaA

- Sundyne

- Klaus Union

- Dickow Pump Company

- ITT Goulds Pumps

- Finish Thompson Inc.

- CDR Pumps

- OPTIMEX

- HERMETIC-Pumpen GmbH

- CP Pumpen AG

- IWAKI CO., LTD.

Get Free Sample For

Get Free Sample For