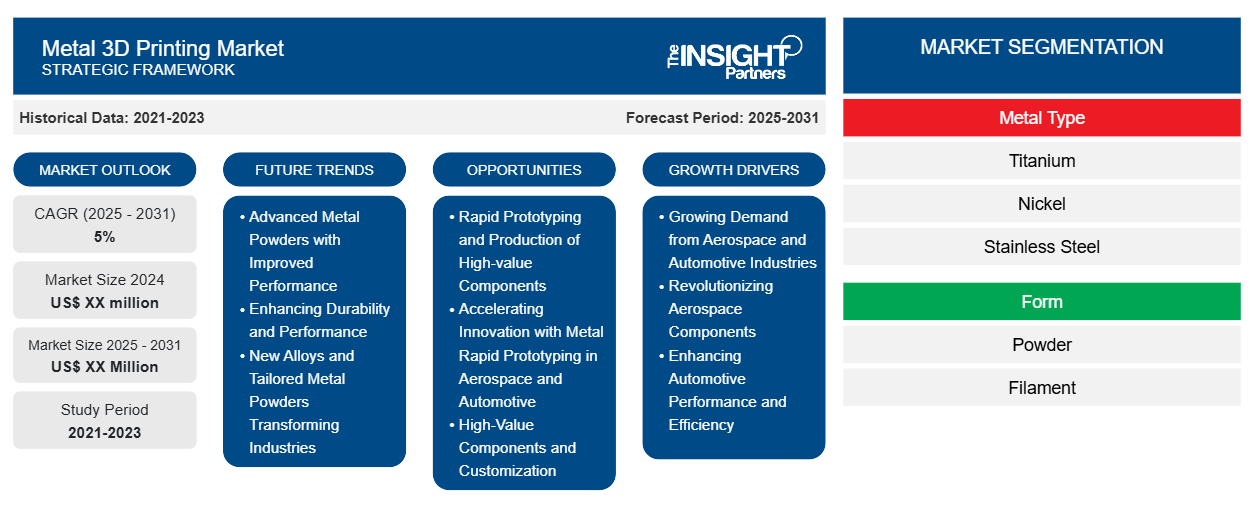

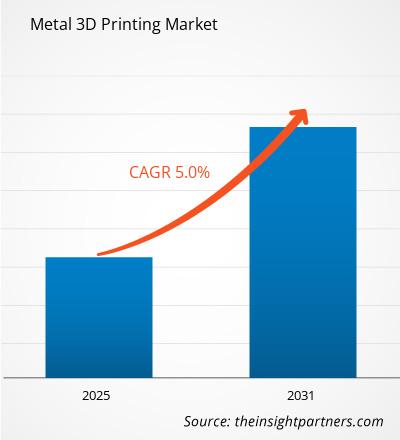

The Metal 3D Printing Market is expected to register a CAGR of 5% from 2025 to 2031, with a market size expanding from US$ XX million in 2024 to US$ XX Million by 2031.

The report is segmented by Metal Type (Titanium, Nickel, Stainless Steel, Aluminum, and Others). The report further presents analysis based on Form (Powder, Filament, and Others). Based on End-Use report is segmented into (Aerospace and Defense, Automotive, Medical, Construction, and Others). The global analysis is further broken-down at regional level and major countries. The Report Offers the Value in USD for the above analysis and segments.

Purpose of the Report

The report Metal 3D Printing Market by The Insight Partners aims to describe the present landscape and future growth, top driving factors, challenges, and opportunities. This will provide insights to various business stakeholders, such as:

- Technology Providers/Manufacturers: To understand the evolving market dynamics and know the potential growth opportunities, enabling them to make informed strategic decisions.

- Investors: To conduct a comprehensive trend analysis regarding the market growth rate, market financial projections, and opportunities that exist across the value chain.

- Regulatory bodies: To regulate policies and police activities in the market with the aim of minimizing abuse, preserving investor trust and confidence, and upholding the integrity and stability of the market.

Metal 3D Printing Market Segmentation

Metal Type

- Titanium

- Nickel

- Stainless Steel

- Aluminum

Form

- Powder

- Filament

End-Use

- Aerospace and Defense

- Automotive

- Medical

- Construction

Geography

- North America

- Europe

- Asia-Pacific

- South and Central America

- Middle East and Africa

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Metal 3D Printing Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Metal 3D Printing Market Growth Drivers

- Growing Demand from Aerospace and Automotive Industries: Aerospace and automotive industries are majorly pulling growth in the metal 3D printing market for lightweight and complex parts making solutions. The two industries focus on reducing weight for better fuel economy, performance, and emissions. Metal 3D printing creates complex designs in reduced weight.

- Revolutionizing Aerospace Components : Metal 3D printing has changed the game for aerospace components, such as turbine blades, brackets, and other structural components. Conventional methods of manufacturing limit one's design, but additive manufacture uses complex geometries that can reduce weight usually without compromising strength. Thus, the new way has made aircraft work better and become even more efficient, which, in turn, drives market growth.

- Enhancing Automotive Performance and Efficiency: Likewise, the automotive sector is embracing the production of lightweight and high-performance components through metal 3D printing. Most of the materials such as titanium, aluminum, and stainless steel used by manufacturers produce very efficient parts, durable but with complex designs. These will improve fuel economy and handling, thus increasing the demand for metal 3D-printing technologies in automotive manufacturing.

Metal 3D Printing Market Future Trends

- Advanced Metal Powders with Improved Performance: High performance advanced metal powders are some of the future trends propelling the growth of the metal 3D printing market. Such powders impart even superior properties, like strength, resistance to heat, and corrosion damage. Such advanced materials become progressively necessary for the 3D printing applications found in industries producing components that must withstand multiple conditions of use and require more durability and high-performance standards.

- Enhancing Durability and Performance: Advanced metal powders enable component manufacture that is capable of withstanding extremes, such as very high temperatures and mechanical stresses in such sectors as aerospace and automotive. It enables the printing of lighter, stronger components having better performance characteristics that produce direct fruits on efficiency and life of critical parts in engines, turbines, and structures in vehicles; this is also propelling growth in the market.

- New Alloys and Tailored Metal Powders Transforming Industries: The development of new alloys and tailored metal powders is also driving the iron innovation in industries such as medical devices and tooling. These "exotic" materials allow for the creation of truly unprecedented complex geometries with properties optimized for specific applications-immediate biocompatibility for implants-or much greater hardness for industrial tools. The more personalization and high quality are required from customers, the faster or higher will be the uptake of advanced metal powders into 3D printing.

Metal 3D Printing Market Opportunities

- Rapid Prototyping and Production of High-value Components: The metal 3D printing market is being significantly fueled by rapid prototyping and high-value component manufacturing. Prototype production continues to shorten design test cycles, development times, and manufacturing processes across industries. This is especially true in the critical areas of aerospace, automotive, and medical devices.

- Accelerating Innovation with Metal Rapid Prototyping in Aerospace and Automotive: In both aerospace and automotive manufacturing, metal rapid prototyping is critical to faster innovation cycles. In rapid prototypes, engineers can quickly iterate designs and make adjustments through testing before reducing time to market. The result is accelerated development, increased accuracy through improved designs, and better-performing and cost-effective components-all adding up to increased demand for technologies associated with metal 3D printing.

- High-Value Components and Customization: Another driving force for the growth of this market is the high-value component manufacturing for turbine blades, engine parts, and pretty complex medical implants. Such high-performance and complex geometrical components, which only metal 3D printing can achieve, cannot be manufactured using conventional engineering methods. Highly customized, strong, but lightweight components, which more often than not, demand specific properties, usually have their value in the aforementioned industries.

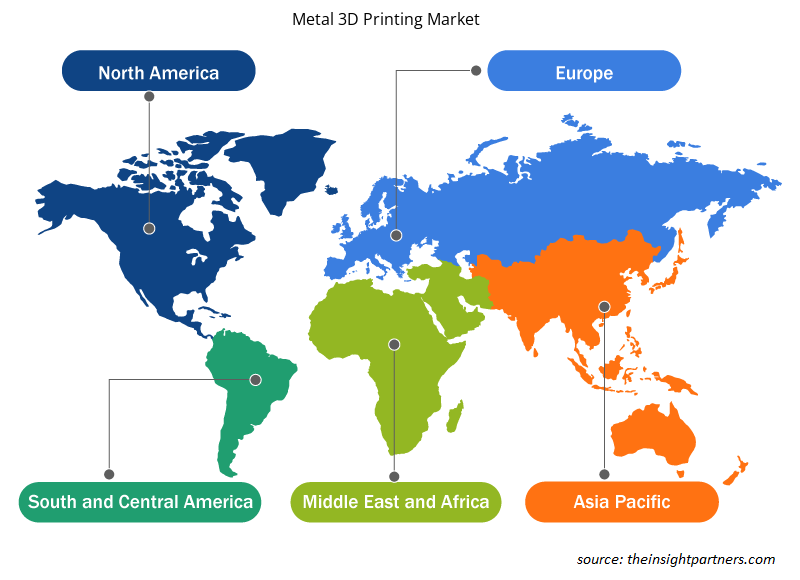

Metal 3D Printing Market Regional Insights

The regional trends and factors influencing the Metal 3D Printing Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Metal 3D Printing Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Metal 3D Printing Market

Metal 3D Printing Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ XX million |

| Market Size by 2031 | US$ XX Million |

| Global CAGR (2025 - 2031) | 5% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Metal Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

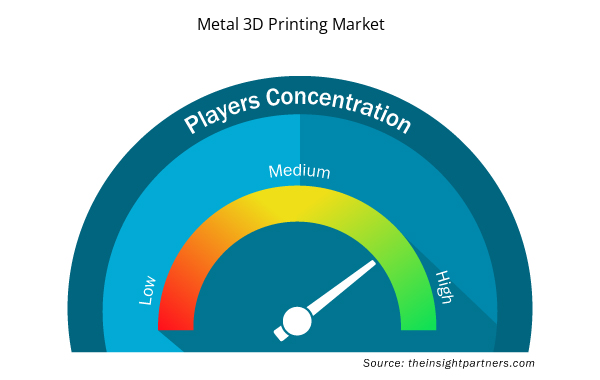

Metal 3D Printing Market Players Density: Understanding Its Impact on Business Dynamics

The Metal 3D Printing Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Metal 3D Printing Market are:

- EOS

- Concept Laser

- SLM Solutions

- Renishaw

- Additive Industries

- GE Additive

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Metal 3D Printing Market top key players overview

Key Selling Points

- Comprehensive Coverage: The report comprehensively covers the analysis of products, services, types, and end users of the Metal 3D Printing Market, providing a holistic landscape.

- Expert Analysis: The report is compiled based on the in-depth understanding of industry experts and analysts.

- Up-to-date Information: The report assures business relevance due to its coverage of recent information and data trends.

- Customization Options: This report can be customized to cater to specific client requirements and suit the business strategies aptly.

The research report on the Metal 3D Printing Market can, therefore, help spearhead the trail of decoding and understanding the industry scenario and growth prospects. Although there can be a few valid concerns, the overall benefits of this report tend to outweigh the disadvantages.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

This text is related

to segments covered.

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

This text is related

to country scope.

Frequently Asked Questions

Advanced Metal Powders with Improved Performance is expected to be the key market trends.

Based on geography, Asia Pacific held the largest share of the metal 3D printing market.

Based on metal type, aluminum is expected to witness the fastest growth during the forecast period

EOS, Concept Laser, SLM Solutions are some of the key players operating in the metal 3D printing market

Growing Demand from Aerospace and Automotive Industries is driving the market growth

The Metal 3D Printing Market is estimated to witness a CAGR of 5% from 2023 to 2031

Get Free Sample For

Get Free Sample For