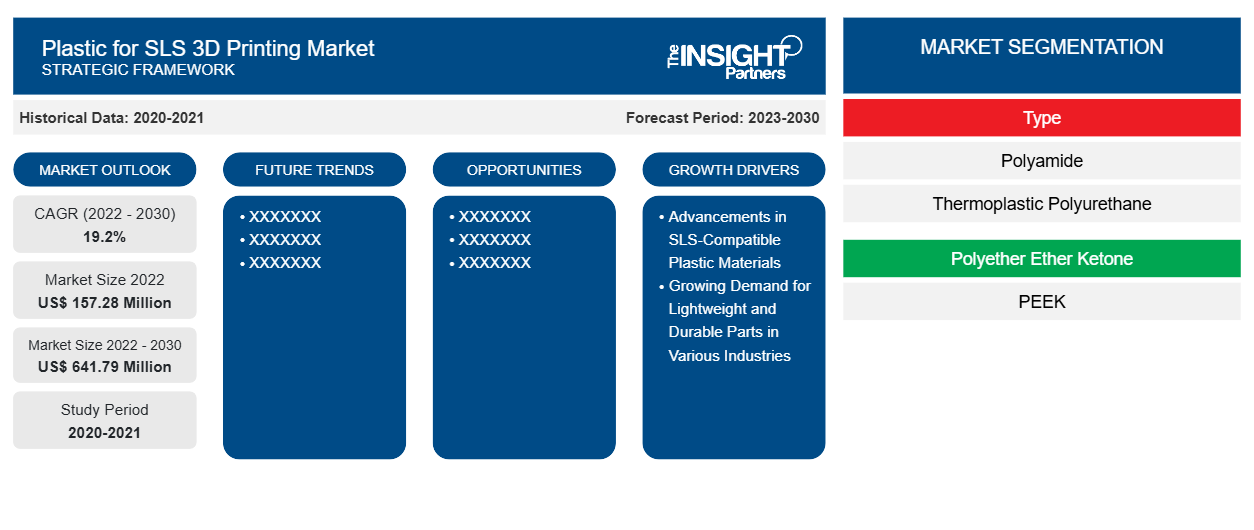

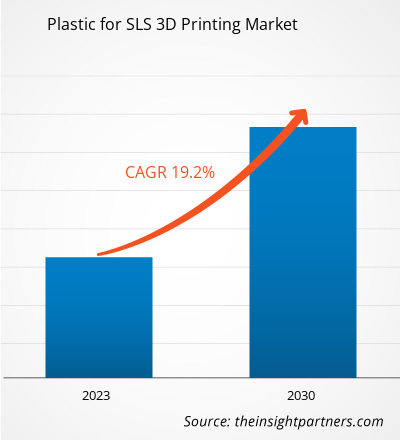

[Research Report] The plastic for SLS 3D printing market size was valued at US$ 157.28 million in 2022 and is projected to reach US$ 641.79 million by 2030; it is anticipated to record a CAGR of 19.2% from 2022 to 2030.

MARKET ANALYSIS

Selective laser sintering (SLS) is an additive manufacturing technology that makes the use of a high-power laser to sinter polymer powder into a solid structure based on a 3D model. SLS 3D printing is a popular choice for engineers and manufacturers. The most common material for SLS 3D printing is nylon. Nylon is a highly capable engineering thermoplastic for functional prototyping and end-use production. It is also ideal for complex assemblies and durable parts with high environmental stability. SLS 3D printing is highly used across a wide range of industries, including engineering, manufacturing, healthcare, and others. The major factors driving the growth of the plastics for the SLS 3D printing market are advancements in SLS-compatible plastic materials and the growing demand for lightweight and durable parts in various industries.

GROWTH DRIVERS AND CHALLENGES

Advancements in SLS-compatible plastic materials and growing demand for lightweight and durable parts in various industries are a few factors boosting the global plastic for SLS 3D printing market growth. Many companies are focused on the continuous development of SLS-compatible plastic materials with improved properties, such as durability, heat resistance, and flexibility. For instance, companies such as HP and BASF have been collaborating to develop innovative SLS materials. In aerospace, where reducing weight is a paramount concern for improving fuel efficiency, SLS-produced plastic components have gained traction. For instance, Airbus has integrated SLS 3D-printed plastic parts into their A350 XWB aircraft, including brackets and ducting components, which contribute to weight reduction without compromising strength or safety. The automotive industry has also embraced SLS plastic parts. Hence, the strong growth in the demand for lightweight plastic parts from various industries is driving the need for plastic for SLS 3D printing, thereby fueling the market growth.

The cost of high-quality SLS-compatible plastic materials can act as a deterrent for cost-conscious businesses considering the adoption of this technology. While SLS offers numerous advantages, including the ability to produce complex parts with strength and durability, the price of materials can be a significant factor in the decision-making process. Hence, the high cost of SLS-compatible plastics limits their use in different application sectors, which hampers the plastic for SLS 3D printing market growth.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Plastic for SLS 3D Printing Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Plastic for SLS 3D Printing Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

REPORT SEGMENTATION AND SCOPE

The "Global Plastic for SLS Printing Market Analysis and Forecast to 2030" is a specialized and in-depth study with a significant focus on global market trends and growth opportunities. The report aims to provide an overview of the global market with detailed market segmentation on the basis of type, end-use industry, and geography. The report provides key statistics on the consumption of plastic for SLS 3D printing across the world, along with their demand in major regions and countries. In addition, the report provides a qualitative assessment of various factors affecting the plastic for SLS 3D printing market performance in major regions and countries. It also includes a comprehensive analysis of the leading players in the plastic for SLS 3D printing market and their key strategic developments. Analysis of the market dynamics is also included to help identify the key driving factors, market trends, and lucrative opportunities, which, in turn, aid in identifying the major revenue pockets.

The ecosystem analysis and Porter’s five forces analysis provide a 360-degree view of the global plastic for SLS 3D printing market, which helps understand the entire supply chain and various factors affecting the market growth.

SEGMENTAL ANALYSIS

The global plastic for SLS 3D printing market is divided on the basis of type and end-use industry. Based on type, the plastic for SLS 3D printing market is segmented into polyamide, thermoplastic polyurethane (TPU), polyether ether ketone (PEEK), and others. The polyamide segment accounted for a significant share of the plastic for SLS 3D printing market in 2022. Polyamide is a preferred material for SLS 3D printing due to its exceptional qualities and adaptability. Among the various types of polyamides used for SLS, polyamide 12 (PA12) is particularly popular. It is majorly utilized for its strength, flexibility, and resistance to chemicals and heat, making it an ideal choice for a wide range of applications. Thermoplastic polyurethane (TPU) is a versatile and increasingly popular material in the SLS 3D printing market. TPU is a type of elastomer that exhibits a remarkable balance of flexibility, durability, and resilience, making it well-suited for a wide range of applications. In the SLS 3D printing market, PEEK offers a unique combination of characteristics that distinguish it from other thermoplastics.

In terms of end-use industry, the market is segmented into healthcare, aerospace & defense, automotive, electronics, and others. Furthermore, the electronics segment held a significant share of the plastic for SLS 3D printing market in 2022. SLS 3D printing technology offers several advantages for producing intricate, customized, and small-scale electronic components. Plastic-based SLS 3D printing is majorly utilized for the manufacturing of customized enclosures and casings for consumer electronics. The primary advantage of using plastic in SLS 3D printing for the automotive sector is its ability to produce complex and lightweight parts that meet the industry's strict performance and safety standards. Plastic materials play a vital role in the rapidly growing field of SLS 3D printing within the healthcare sector. These versatile polymers are being extensively utilized for various applications owing to their biocompatibility, ease of customization, and cost-effectiveness.

REGIONAL ANALYSIS

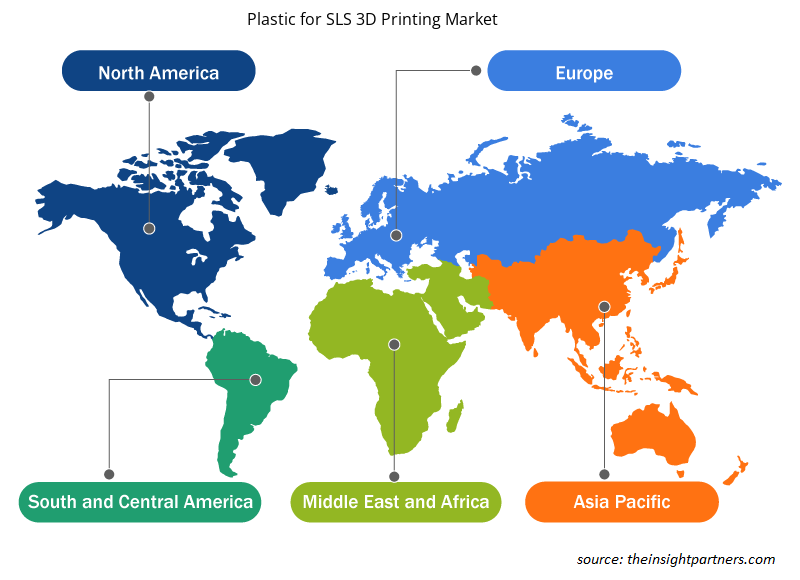

The report provides a detailed overview of the global plastic for SLS 3D printing market with respect to five major regions—North America, Europe, Asia-Pacific (APAC), the Middle East & Africa (MEA), and South & Central America. Europe accounted for a significant share of plastic for SLS 3D printing market and was valued at more than US$ 55 million in 2022. The automotive industry in Europe is constantly seeking ways to reduce vehicle weight to improve fuel efficiency and performance. Further, the growing automotive industry in the region is expected to drive the demand for plastics for SLS 3D printing. The Asia Pacific plastic for SLS 3D printing market is expected to reach more than US$ 110 million by 2030. Asia Pacific is home to a few of the world’s largest manufacturing economies, such as China, Japan, and South Korea. These countries are investing heavily in advanced manufacturing technologies such as SLS 3D printing. The region also has the presence of additive manufacturing and SLS 3D printing companies, which is further expected to boost the growth of the plastics for SLS 3D printing market during the forecast period. The North America plastic for SLS 3D printing market is expected to record a CAGR of ~18% from 2022 to 2030. The presence of SLS 3D printing companies in the region is further expected to boost the demand for plastics for SLS 3D printing. SLS 3D printing companies are strategizing business expansion to cater to the growing demand from end-use industries. The growth of automotive and aerospace industries in the region is further anticipated to create lucrative opportunities for the plastics for SLS 3D printing market in the coming years.

INDUSTRY DEVELOPMENTS AND FUTURE OPPORTUNITIES

Various initiatives taken by the key players operating in the plastic for SLS 3D printing market are listed below:

- In June 2023, 3D Systems announced collaboration with SWANY Co Ltd to promote the adoption of large-format pellet extrusion 3D printing in Japan.

- In February 2021, 3D Systems introduced a High-Speed Fusion industrial 3D printer platform and material portfolio, in a collaboration with Jabil Inc.

- In October 2022, Evonik intended to improve overall eco-balances by aligning its INFINAM polyamide 12 (PA12) powders, by introducing a PA12 powders with much lower CO2 emissions.

Plastic for SLS 3D Printing Market Regional Insights

Plastic for SLS 3D Printing Market Regional Insights

The regional trends and factors influencing the Plastic for SLS 3D Printing Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Plastic for SLS 3D Printing Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Plastic for SLS 3D Printing Market

Plastic for SLS 3D Printing Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2022 | US$ 157.28 Million |

| Market Size by 2030 | US$ 641.79 Million |

| Global CAGR (2022 - 2030) | 19.2% |

| Historical Data | 2020-2021 |

| Forecast period | 2023-2030 |

| Segments Covered |

By Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

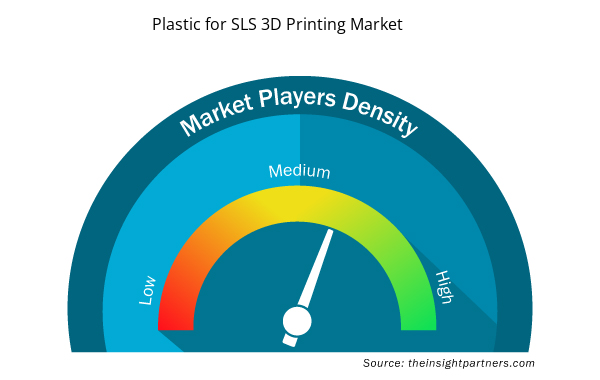

Plastic for SLS 3D Printing Market Players Density: Understanding Its Impact on Business Dynamics

The Plastic for SLS 3D Printing Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Plastic for SLS 3D Printing Market are:

- 3D Systems Corp

- BASF SE

- Evonik Industries AG

- Arkema SA

- Ensinger GmbH

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Plastic for SLS 3D Printing Market top key players overview

IMPACT OF COVID-19 PANDEMIC/IMPACT OF GEOPOLITICAL SCENARIO/IMPACT OF RECESSION

Before the COVID-19 pandemic, many countries across the globe reported economic growth. The key manufacturers invested in the research and development of plastic for SLS 3D printing. They also focused on the expansion of geographic reach through merger and acquisition strategies to cater to a wide customer base. During the pandemic, supply chain disruptions, raw material and labor shortages, and operational difficulties created a demand and supply gap, which adversely affected the growth of plastic for SLS 3D printing market. Manufacturers reported challenges in sourcing raw materials and ingredients from suppliers, thereby impacting the production rate of plastic for SLS 3D printing. Further, production shortfall caused by severe disruptions in supply chains and limited skilled laborers created a demand-supply gap in many regions, particularly Asia Pacific, Europe, and North America. The demand and supply gap were also recorded in the aforementioned regions due to fluctuating demand from the automotive industry.

The sales of plastic for SLS 3D printing increased with the resumption of 3D printing services. The plastic for SLS 3D printing market began reviving as governments of various countries took significant measures, such as well-coordinated vaccination drives. With the recovery of operations of the automotive and aerospace & defense sectors, the demand for 3D printing materials has been growing. In addition, the expansion of the electronics sector across the globe is boosting the demand for plastic for SLS 3D printing.

COMPETITIVE LANDSCAPE AND KEY COMPANIES

3D Systems Corp, BASF SE, Evonik Industries AG, Arkema SA, Ensinger GmbH, Fiberlab SA, Stratasys Ltd, Sinterit Sp Zoo, EOS GmbH, and CRP Service SRL are among the key players operating in the plastic for SLS 3D printing market.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

- Health Economics and Outcome Research (HEOR) Services Market

- Personality Assessment Solution Market

- Photo Editing Software Market

- Sports Technology Market

- Mesotherapy Market

- Integrated Platform Management System Market

- Aesthetic Medical Devices Market

- Piling Machines Market

- Saudi Arabia Drywall Panels Market

- Dealer Management System Market

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Type, and End-Use Industry

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

This text is related

to country scope.

Frequently Asked Questions

The increasing demand for SLS 3D printing from the healthcare industry, is expected to provide lucrative growth opportunities to the global plastic for SLS 3D printing market during the forecast period.

Based on end-use industry, automotive is the fastest-growing segment. Plastic SLS 3D printing has been employed in the production of end-use parts, including interior panels, dashboard components, and even lightweight structural elements, where the combination of strength and reduced weight is paramount for improved fuel efficiency and overall vehicle performance.

Europe plastic for SLS 3D printing market is expected to surge due to the growing automotive and aerospace industry in the region. The automotive industry in Europe is constantly seeking ways to reduce vehicle weight to improve fuel efficiency and performance. Therefore, Europe accounts for the largest share of the global plastic for SLS 3D printing market.

Based on the type, the polyamide segment accounted for the largest revenue share. Polyamide offers several advantages such as superior impact strength and excellent layer adhesion, making it well-suited for applications requiring both mechanical integrity and resilience. Therefore, this factor is expected to boost the polyamide share in the market.

The major players operating in the global plastic for SLS 3D printing market are 3D Systems Corp, BASF SE, Evonik Industries AG, Arkema SA, and Fiberlab SA amongst others.

Advancements in SLS-compatible plastic materials and growing demand for lightweight and durable parts in various industries, are some of the key driving factors for the plastic for SLS 3D printing market.

Trends and growth analysis reports related to Chemicals and Materials : READ MORE..

The List of Companies - Plastic for SLS 3D Printing Market

- 3D Systems Corp

- BASF SE

- Evonik Industries AG

- Arkema SA

- Ensinger GmbH

- Fiberlab SA

- Stratasys Ltd

- Sinterit Sp Zoo

- EOS Gmb

- CRP Service SRL

Get Free Sample For

Get Free Sample For