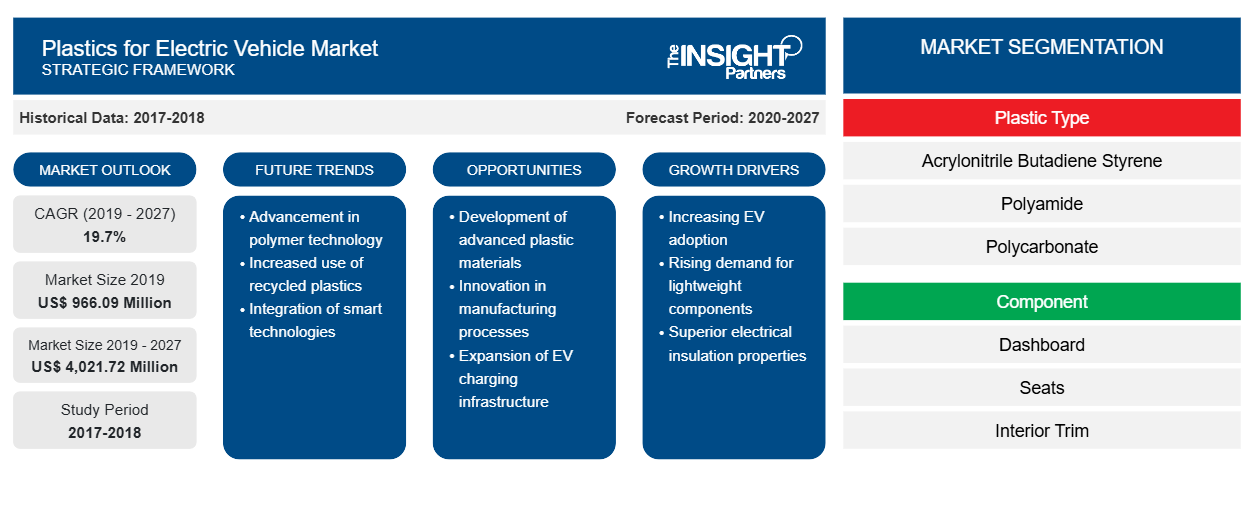

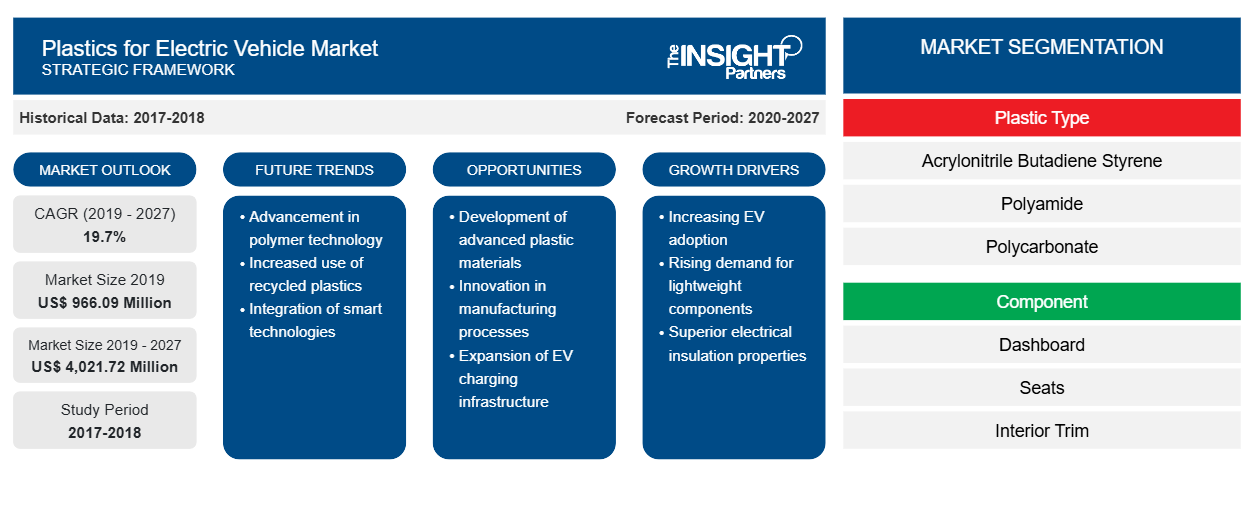

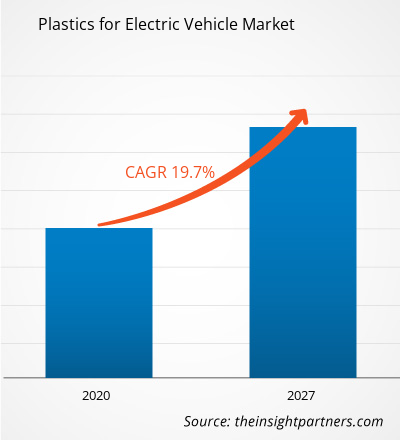

The plastic for electric vehicle market was valued at US$ 966.09 million in 2019 and is projected to reach US$ 4,021.72 million by 2027; it is expected to grow at a CAGR of 19.7% from 2020 to 2027.

Plastics can be an electric conductor and also an insulator. Thermoplastics polymer can be produced in various shapes and designs as per the requirement of electric vehicles due to the high versatility and easy moldability of plastics. The use of plastics for electric vehicles reduces the weight of these vehicles, which provides a greater range between recharges. Plastics offer excellent heat resistance that enables the construction of battery compartments and cooling systems and do not hamper the durability and safety provided by electric vehicles. The global plastic for electric vehicle market in North America is expected to grow at the highest CAGR of 20.0% during 2020–2027.

The COVID-19 pandemic was first reported in Wuhan (China) in December 2019. As of June 2020, the US, Russia, India, Spain, Brazil, Italy, France, and Germany are among the worst-affected countries in terms of the COVID-19 positive cases and reported deaths. The outbreak is adversely affecting economies and industries due to lockdowns, travel bans, and business shutdowns. Chemicals and materials is one the world’s major industries suffering serious disruptions in the form of supply chain disruptions, technology events cancellations, and office shutdowns. China is the global manufacturing hub and the largest raw material supplier for various industries across the world, and it is also one of the worst hit countries by the COVID-19 pandemic. The lockdown of various plants and factories in China is restricting the global supply chains, and manufacturing and sales of various chemicals and materials products. The overall impact of the pandemic is consequently restraining the growth of the plastic for electric vehicle market.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Plastics for Electric Vehicle Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Plastics for Electric Vehicle Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Market Insights

Rising Demand of Electric Vehicles Drives Market Growth

Automobile manufacturing is shifting toward generating less emissions of greenhouse gases and becoming fuel-efficient with the growing emphasis on environmental sustainability. Cost-effectiveness; environment sustainability; convenience; adoption of advanced technology; and various government policies such as preferential rates, incentives toward equipment purchase, and significant rebates are among the factors propelling the demand for electric vehicles across the world. According to IEA, 40% year-on-year increase has been registered with the sales of 2.1 million electric cars globally in 2019, significantly surpassing that of 2018.

Plastic Type Insights

Based on plastic type, the plastic for electric vehicle market is segmented into Acrylonitrile Butadiene Styrene (ABS), Polyamide (PA), Polycarbonate (PC), Polyvinyl Butyral, Polyurethane (PU), Polypropylene (PP), and Others. The Polypropylene (PP) segment accounted for the largest share of the market in 2019. Polypropylene (PP) refers to a thermoplastic “addition polymer” that is produced by combining propylene monomers. It is rigid and crystalline; therefore, it is widely used to make objects such as packaging trays, medical devices, and others. As one of the important family of polyolefin resins, it is molded and extruded into any plastic type that require flexibility, toughness, lightweight and heat resistance.

Component Insights

Based on component, the plastic for electric vehicle market is segmented into dashboard, seats, interior trim, car upholstery, bumper, and others. The interior trim segment accounted for the largest share of the market in 2019. The interior trim in an electric vehicle refers to the plastic components or panels that are present inside the cabin. Functional and aesthetic trim with pleasing features are essential for providing a perfect interior experience.

Vehicle Type Insights

Based on vehicle type, the plastic for electric vehicle market is bifurcated into BEV and PHEV/HEV. The BEV segment accounted for the largest share of the market in 2019. Battery electric vehicles or BEVs store electricity on board with high capacity packs of batteries. The power in the battery is used to run the electric motor and other electronics on board. Plastics are used in the making of connectors and housings for the electrical components that are required in the electric vehicles.

Application Insights

Based on application, the plastic for electric vehicle market is further segmented into powertrain system/under bonnet, exterior, interior, and lighting & electric wiring. The interior segment accounted for the largest share of the market in 2019. High performance plastics are used in electric vehicles with providing safety and security. Polypropylene is frequently used in the car parts such as gas cans and carpet fibers of the interior flooring. PVC is used in the car tanks and dashboards due to its sleek finish. Steering wheels and dashboards are also produced with acrylonitrile butadiene styrene or ABS plastics. The wide scale application of plastics in the steering wheels, interior flooring, and consoles favors the growth of the plastics for electric vehicle market for interior trim segment.

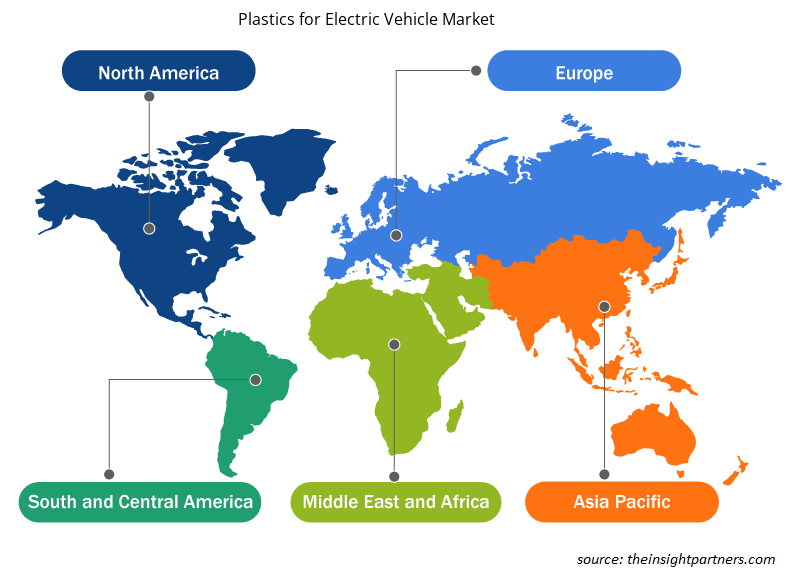

Plastics for Electric Vehicle Market Regional Insights

The regional trends and factors influencing the Plastics for Electric Vehicle Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Plastics for Electric Vehicle Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Plastics for Electric Vehicle Market

Plastics for Electric Vehicle Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2019 | US$ 966.09 Million |

| Market Size by 2027 | US$ 4,021.72 Million |

| Global CAGR (2019 - 2027) | 19.7% |

| Historical Data | 2017-2018 |

| Forecast period | 2020-2027 |

| Segments Covered |

By Plastic Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

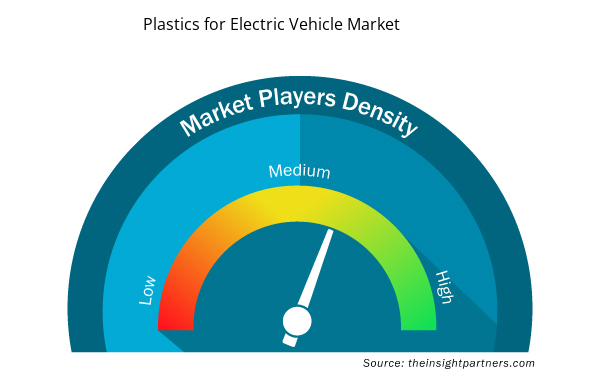

Plastics for Electric Vehicle Market Players Density: Understanding Its Impact on Business Dynamics

The Plastics for Electric Vehicle Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Plastics for Electric Vehicle Market are:

- BASF SE

- Solvay S.A.

- DuPont de Nemours, Inc.

- The Dow Chemical Company

- LG Chem Ltd

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Plastics for Electric Vehicle Market top key players overview

Report Spotlights

- Progressive industry trends in the global plastic for electric vehicle market that help players develop effective long-term strategies

- Business growth strategies adopted by developed and developing markets

- Quantitative analysis of the plastic for electric vehicle market from 2017 to 2027

- Estimation of plastic for electric vehicle demand across various industries globally

- PEST analysis to illustrate the efficacy of buyers and suppliers operating in the market

- Recent developments to understand the competitive market scenario and the demand for plastic for electric vehicle

- Market trends and outlook, and factors driving and restraining the growth of the market

- Understanding on strategies that underpin the global plastic for electric vehicle market growth, which assists stakeholders in decision making

- Plastic for electric vehicle market size at various nodes of market

- Detailed overview and segmentation of the market, and industry dynamics

- Global plastic for electric vehicle market size in various regions with promising growth opportunities in the these regions

Plastic for Electric Vehicle Market, by Plastic Type

- Acrylonitrile Butadiene Styrene

- Polyamide

- Polycarbonate

- Polyvinyl Butyral

- Polyurethane

- Polypropylene

- Others

Plastic for Electric Vehicle Market, by Component

- Dashboard

- Seats

- Interior Trim

- Car Upholstery

- Bumper

- Others

Plastic for Electric Vehicle Market, by Vehicle Type

- BEV

- PHEV/HEV

Plastic for Electric Vehicle Market, by Application

- Powertrain System/ Under Bonnet

- Exterior

- Interior

- Lighting and Electric Wiring

Company Profiles

- BASF SE

- Solvay SA

- DuPont de Nemours, Inc.

- The Dow Chemical Company

- LG Chem Ltd.

- Lanxess AG

- Sabic

- Covestro AG

- Asahi Kasei Corporation

- Lyondellbasell Industries Holdings B.V.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Plastic Type , Component , Vehicle Type , and Application

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

Argentina, Australia, Brazil, Canada, China, France, Germany, India, Italy, Japan, Mexico, Russian Federation, Saudi Arabia, South Africa, South Korea, United Arab Emirates, United Kingdom, United States

Frequently Asked Questions

In 2019, Asia Pacific held the largest share of the global plastics for electric vehicles market. The demand for plastics for electric vehicles is expected to increase in the region with the increase in the educated population who demand for more and more electric vehicles. The rise in disposable income and per capita consumption supports the market growth. The rising production capacities of the manufacturers of plastics favors the growth of plastics for electric vehicles market in the region. Continuous innovations in the application of plastics for electric vehicles is yet another factor driving the demand for plastics for electric vehicles. Besides these, rising awareness about the benefits of electric vehicles and initiatives taken by the Government for supporting the demand for plastics for electric vehicles, provides lucrative opportunity for the development of plastics for electric vehicles market in Asia Pacific.

The growth of polyurethane segment is primarily attributed to the fact that polyurethane (PU) is considered to be one of the most versatile plastic materials. It is formed by the reaction of polyol along with a di- isocyanate or a polymeric isocyanate in the presence of an additive or a catalyst. Polyurethane structure comprises of three complex monomers namely, diisocyanate, a macrodial and chain extender, on the basis of which many polyurethane materials can be synthesized. The polyurethane polymers are also characterized by the presence of urethane linkage. Depending on the length and nature of the hydroxyl and isocyanate molecule, the thermoplastic, hard, soft, flexible and cellular type of polyurethane is synthesized. The resultant structure resembles that of polyamide as both of them comprises of CONH groups. Polyurethane possess versatile properties like toughness, biocompatibility and durability that can be tailored depending on the application. In electronic vehicles, the engineers prefer using thermoset polyurethane adhesives for the purpose of bonding the dissimilar materials to the frame of cars. These adhesives are strong and helps in reducing the need for heavy and bulky bolts & rivets. They also help in keeping down the weight of the vehicle curb thus making the cars light & fast along with excellent charge range. Polyurethane is also used in shock absorption components in vehicles. The automakers also prefer using cast polyurethane in muffler systems. It is extensively used in electric vehicle car batteries and provide smoothest driving experience. All these factors are responsible for polyurethane segment to grow at the high rate.

The major players operating in the global plastics for electrical vehicle market are BASF SE, Solvay S.A., DuPont de Nemours, Inc., The Dow Chemical Company, LG Chem Ltd, Lanxess AG, Sabic, Covestro AG, Asahi Kasei Corporation and LyondellBasell Industries Holdings B.V.

Trends and growth analysis reports related to Chemicals and Materials : READ MORE..

The List of Companies - Global Plastics for Electric Vehicle Market

- BASF SE

- Solvay S.A.

- DuPont de Nemours, Inc.

- The Dow Chemical Company

- LG Chem Ltd

- Lanxess AG

- Sabic

- Covestro AG

- Asahi Kasei Corporation

- LyondellBasell Industries Holdings B.V

Get Free Sample For

Get Free Sample For