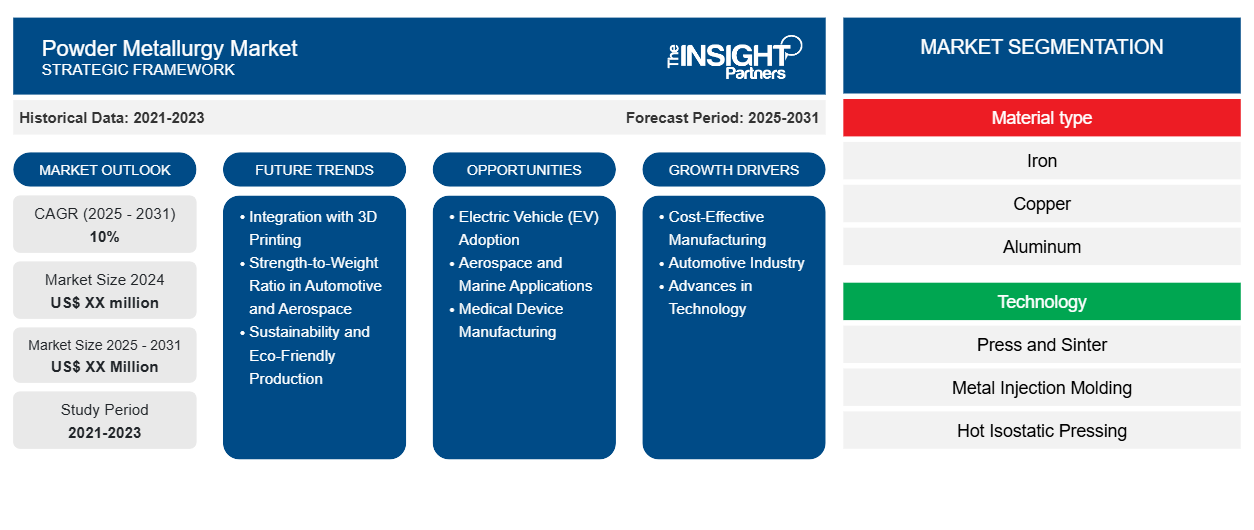

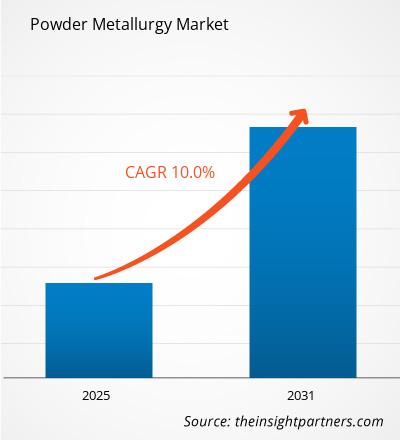

The Powder Metallurgy Market is expected to register a CAGR of 10% from 2025 to 2031, with a market size expanding from US$ XX million in 2024 to US$ XX Million by 2031.

The report is segmented by material type (iron, copper, aluminum, steel, others), technology (press and sinter, metal injection molding, hot isostatic pressing, metal additive manufacturing, others). The report further presents analysis based on application (automotive, electronics, aerospace, medical, oil and gas, others). Global analysis is further broken-down at regional level and major countries. In terms of geography, the market is divided into North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America). The report offers the Value in USD for the above analysis and segments.

Purpose of the Report

The report Powder Metallurgy Market by The Insight Partners aims to describe the present landscape and future growth, top driving factors, challenges, and opportunities. This will provide insights to various business stakeholders, such as:

- Technology Providers/Manufacturers: To understand the evolving market dynamics and know the potential growth opportunities, enabling them to make informed strategic decisions.

- Investors: To conduct a comprehensive trend analysis regarding the market growth rate, market financial projections, and opportunities that exist across the value chain.

- Regulatory bodies: To regulate policies and police activities in the market with the aim of minimizing abuse, preserving investor trust and confidence, and upholding the integrity and stability of the market.

Powder Metallurgy Market Segmentation

Material type

- Iron

- Copper

- Aluminum

- Steel

- Others

Technology

- Press and Sinter

- Metal Injection Molding

- Hot Isostatic Pressing

- Metal Additive Manufacturing

- Others

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Powder Metallurgy Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Powder Metallurgy Market Growth Drivers

- Cost-Effective Manufacturing: As compared to classical manufacturing processes, powder metallurgy also presents a low cost of manufacturing complex and high precision parts. It avoids unnecessary materials above all, consumes less energy and minimizes further processing, which makes it appealing in sectors, such as automobile, aerospace and electronics.

- Automotive Industry: Another sector that powder metallurgy finds a substantial application is the automotive industry, which uses technology to design and develop weight-saving design features of engineered products. With an electric and fuel efficiency cars global trend, more engine parts, gears and structural components are made out of powder metallurgy technique.

- Advances in Technology: Market development is stoked by advances in powder metallurgy including new alloy systems, newer sintering methods and 3D printing incorporated powder metallurgy. Such improvements make powder metallurgy parts in high strength and toughness and broaden the use of this technology in aerospace, medical and industrial machines.

Powder Metallurgy Market Future Trends

- Integration with 3D Printing: A noteworthy development is the increased application of powder metallurgy processes in 3D printing. The nature of additive manufacturing permits the production of intricate parts with high accuracy from 3D models, including those made with powdered metals, hence the growing use of powder metallurgy in various sectors such as aerospace, automotive, and medical.

- Strength-to-Weight Ratio in Automotive and Aerospace: At the same time, there is a surge in the need for the automotive and aerospace industries to incorporate high strength to weight ratio materials. The response to this challenge is of course.

This challenge is being addressed by the evolution of powder metallurgy, which allows creating durable low-weight elements using most often new alloys and composites, which help reduce the fuel consumption and enhance the performance of motor vehicles.

- Sustainability and Eco-Friendly Production: Powder metallurgy is beneficial in offering solutions to the production processes that are eco-friendly as awareness on climate change poses a threat to the use of this technology. The reuse of metal powders and the reduction of material loss in relation to the growing demand for sustainable manufacturing makes penggunaan powder metallurgy suitable for green technologies and industries that have to be mindful of their impact on the environment.

Powder Metallurgy Market Opportunities

- Electric Vehicle (EV) Adoption: The soaring adoption of electric vehicles provides an ample scope for powder metallurgy. There has emerged a requirement for lightweight and high efficiency components such as motors, gears and battery housings, which is well suited for the mass production of parts that are affordable and hard wearing, hence boosting the growth of the market.

- Aerospace and Marine Applications: The capacity of powder metallurgy to make highly intricate and exact components creates a market niche in the manufacture of aerial and marine wares. High value, low weight, and heat resistant joints like, turbine blades, relevant structural and bearing parts and geares has led powder metallurgy is a critical manufacturing process for these industries.

- Medical Device Manufacturing: The expanding market for medical devices creates windows through which powder metallurgy can innovate, especially in the development of strong and custom-made implants and surgical equipment. Such process is effective in the production of orthopaedic medical devices because of its ability to fabricate complex shapes using biocompatible materials.

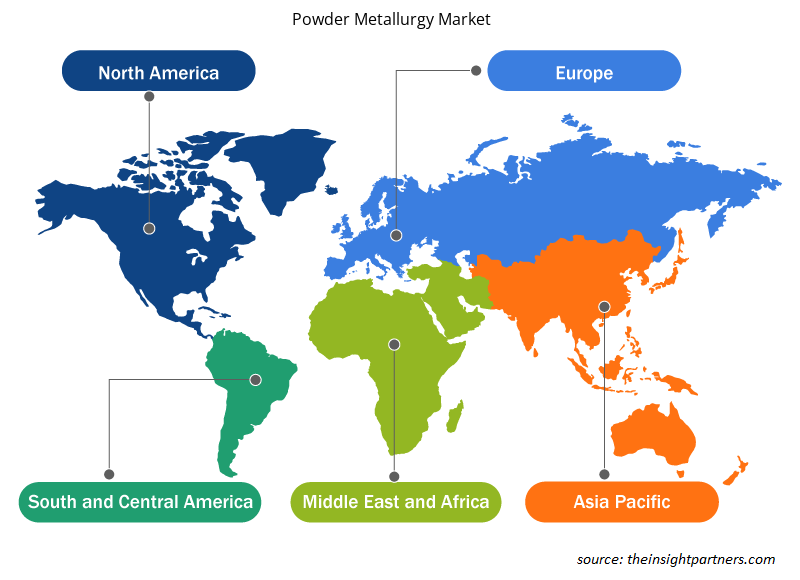

Powder Metallurgy Market Regional Insights

The regional trends and factors influencing the Powder Metallurgy Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Powder Metallurgy Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Powder Metallurgy Market

Powder Metallurgy Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ XX million |

| Market Size by 2031 | US$ XX Million |

| Global CAGR (2025 - 2031) | 10% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Material type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

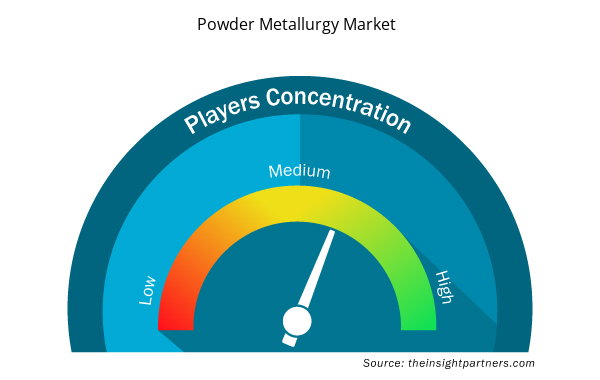

Powder Metallurgy Market Players Density: Understanding Its Impact on Business Dynamics

The Powder Metallurgy Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Powder Metallurgy Market are:

- GENERAL ELECTRIC

- CRS Holdings Inc.

- ExOne GmbH

- Melrose Industries PLC

- Höganäs AB

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Powder Metallurgy Market top key players overview

Key Selling Points

- Comprehensive Coverage: The report comprehensively covers the analysis of products, services, types, and end users of the Powder Metallurgy Market, providing a holistic landscape.

- Expert Analysis: The report is compiled based on the in-depth understanding of industry experts and analysts.

- Up-to-date Information: The report assures business relevance due to its coverage of recent information and data trends.

- Customization Options: This report can be customized to cater to specific client requirements and suit the business strategies aptly.

The research report on the Powder Metallurgy Market can, therefore, help spearhead the trail of decoding and understanding the industry scenario and growth prospects. Although there can be a few valid concerns, the overall benefits of this report tend to outweigh the disadvantages.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

This text is related

to segments covered.

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

This text is related

to country scope.

Frequently Asked Questions

The report can be delivered in PDF/Word format, we can also share excel data sheet based on request.

Based on geography, North America held the largest share of the powder metallurgy market.

The growing use of powder metallurgy in 3D printing is a significant trend in the market.

GENERAL ELECTRIC, CRS Holdings Inc., ExOne GmbH, Melrose Industries PLC, Höganäs AB, Hitachi Chemical Company Ltd, GKN Sinter Metals Engineering GmbH, Sumitomo Electric Company Ltd., Fine Sinter Company Ltd, Schunk Group are the key players operating in the powder metallurgy market.

Powder metallurgy offers a cost-efficient manufacturing process compared to traditional methods. This cost effectiveness acts as a major driver of the market growth.

The Powder Metallurgy Market is estimated to witness a CAGR of 10% from 2023 to 2031

Trends and growth analysis reports related to Chemicals and Materials : READ MORE..

1. GENERAL ELECTRIC

2. CRS Holdings Inc.

3. ExOne GmbH

4. Melrose Industries PLC

5. Höganäs AB

6. Hitachi Chemical Company Ltd

7. GKN Sinter Metals Engineering GmbH

8. Sumitomo Electric Company Ltd.

9. Fine Sinter Company Ltd

10. Schunk Group

Get Free Sample For

Get Free Sample For