The ceramic injection molding market is projected to reach US$ 603.17 million by 2028; registering at a CAGR of 8.3% from 2022 to 2028, according to a new research study conducted by The Insight Partners

Various Advantages Offered by Ceramic Injection Molding to Drive its Market

The ceramic injection molding process is a type of powder injection molding which involves mixing ceramic powders such as alumina and zirconia with binders to form a feedstock which is then molded in a die cavity to form the desired component. The process is similar to metal powder injection molding process. By utilizing this technology, injection-molded ceramic parts of intricate geometries such as sockets, bearings, mobile phone buttons, dental implants, specific laptop keypads, and others could be manufactured with high precision and negligible wastage. Ceramic injection molding helps to obtain intricate designs using a cost-effective process. When a ceramic material is chosen for a specific application, the component's geometry has often been limited by the cost of shaping operations. Ceramic injection molding helps to overcome this issue by forming net shape parts in the tool. This makes it commercially feasible for previously rejected designs that were too difficult or expensive to manufacture using other traditional production techniques. Due to ceramics' inherent hardness, manufacturing components with complex shapes by standard machining processes can be expensive. Features such as multi-shaped blind holes, re-entrant angles, surface profiles, perpendicular holes, screw threads, undercuts, and intricate cavities are possible using ceramic injection molding technology. Therefore, various advantages offered by ceramic injection molding to drive ceramic injection molding market growth.

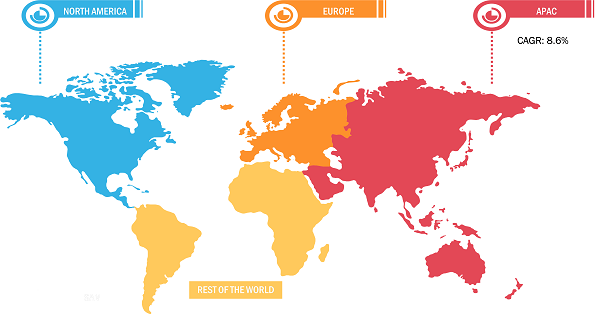

Ceramic Injection Molding Market Breakdown – by Region

Ceramic Injection Molding Market Forecast to 2028 - COVID-19 and Global Analysis by Type (Alumina, Zirconia, and Others) and Industrial Verticals (Industrial Machinery, Automotive, Healthcare, Electricals and Electronics, Consumer Goods, and Others)

Ceramic Injection Molding Market Trends and Scope by 2028

Download Free Sample

Key players operating in the global ceramic injection molding market include AMT Pte. Ltd.; Arburg GmbH + Ko. KG.; Ceramco, Inc.; CoorsTek, Inc.; Indo MIM; KLAGER; Micro; Morgan Advanced Materials; Nishimura; Advanced Ceramics, Co. Ltd.; and OECHSLER AG. These companies have a widespread global presence, which allows them to serve a large set of customers worldwide and subsequently increase their market share. They heavily focus on new product launches and geographical expansion to expand their product range in specialty portfolios.

Impact of COVID-19 Pandemic on Ceramic Injection Molding Market

The US has the highest number of confirmed cases of COVID-19, as, compared to Canada and Mexico. This is likely to impact the consumer chemical and materials industry in the region as, due to the COVID-19, the supply chain is likely to get affected. In addition, the overall manufacturing processes, research, and development activities will also impact market growth.

In Europe, as per the recent data, Russia has recorded the highest number of COVID cases. Other than this, Spain, Germany, France and UK have also been hit hard and are expected to suffer an economic hit due to a lack of revenue from various industries. Other member states have implemented drastic measures and travel restrictions, including partially closing their borders. This is anticipated to impact market growth in Europe.

Moreover, the demand for luxury goods, non-essential consumer goods, and decorative items also dropped as many retail stores were closed due to lockdowns and economic crunch created by the pandemic. This affected the demand for decorative ceramics, which thereby hampered the ceramic injection molding market growth. Further, the automotive industry also witnessed slump in automobile sales due to the pandemic-induced economic recession. The production activities of automobile manufacturers were hampered due to stringent government regulations and disruption of supply chains. There was a significant shortage of raw materials and labor which created a demand-supply gap and hampered the profitability of large-scale as well as small-scale automobile manufacturers. This also had a negative impact on the demand for ceramic injection molding for manufacturing automotive parts, which negatively impacted the ceramic injection molding market growth.

The report segments the ceramic injection molding market as follows:

Based on type, the ceramic injection molding market is segmented into alumina, zirconia, and others. Based on industrial verticals, the market is segmented into industrial machinery, automotive, healthcare, electrical and electronics, consumer goods, and others. Based on geography, the ceramic injection molding market is segmented into North America, Europe, Asia Pacific (APAC), the Middle East & Africa (MEA), and South & Central America.

Contact Us

Phone: +1-646-491-9876

Email Id: sales@theinsightpartners.com