Chemical Surface Treatment Market: Key Insights

The chemical surface treatment market is driven by the increasing demand for high-quality, durable, and corrosion-resistant surfaces in various automotive, aerospace, and construction industries. Technological advancements in surface treatments and the growing awareness of the benefits of chemical surface treatments are also contributing to the market's growth. In addition, the increasing use of chemical surface treatments in various industrial applications, such as metal finishing and surface hardening, is expected to create growth opportunities for the chemical surface treatment market in the future.

However, environmental concerns related to the use and disposal of chemical surface treatment products are a major challenge faced by the market. In addition, the high cost of chemical surface treatments and the complex regulations related to their use are also limiting the market's growth. Despite these challenges, the growing adoption of chemical surface treatments in developing countries are expected to provide decent growth opportunities for the chemical surface treatment market in the future.

Chemical Surface Treatment Market

Chemical Surface Treatment Market Size and Forecasts (2021 - 2031), Global and Regional Share, Trends, and Growth Opportunity Analysis Report Coverage: By Chemical Type (Cleaners, Plating Chemicals, Conversion Coating, Others); Base Material (Metals, Plastics, Others); End User Industry (Transportation, Construction, General Industry, Packaging, Industrial Machinery, Others) , and Geography (North America, Europe, Asia Pacific, and South and Central America)

Chemical Surface Treatment Market Growth | 2021 to 2031

Download Free Sample

Increasing Demand for Surface Treatment of Medical Devices is Driving the Chemical Surface Treatment Market

The increasing demand for surface treatment of medical devices is a major factor driving the growth of the chemical surface treatment market. Medical devices such as implants, prosthetics, and surgical instruments require high levels of surface quality and durability to ensure their safe and effective performance. Chemical surface treatments such as passivation, anodization, and electroplating can improve the corrosion resistance, wear resistance, and biocompatibility of these devices. In addition, the high demand for minimally invasive medical procedures and the increasing use of implantable devices are driving the demand for chemical surface treatments in the medical device industry. These treatments can help to improve the longevity and reliability of medical devices, reducing the need for frequent replacement and ensuring patient safety. Furthermore, the trend toward using biocompatible materials in medical devices is also driving the demand for chemical surface treatments. The use of chemical treatments can improve the biocompatibility of materials and reduce the risk of adverse reactions, making them suitable for use in medical devices.

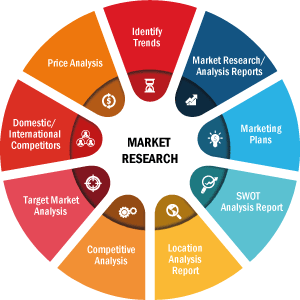

Chemical Surface Treatment Market: Segmental Overview

The chemical surface treatment market is segmented on the basis of chemical type, base material, end use industry. On the basis of chemical type, the chemical surface treatment market is segmented into, cleaners, plating chemicals, conversion coating, and others. On the basis of base material, the chemical surface treatment market is segmented metals, plastics, and others. On the basis of end use industry, the chemical surface treatment market is segmented into, transportation, construction, packaging, industrial machinery, and others.

Plating chemicals are expected to hold a substantial market share due to their wide range of applications. Plating chemicals are used in electroplating processes to deposit metal or metal alloys onto the surface of various materials such as metals, plastics, and ceramics. They are widely used in industries such as automotive, aerospace, electronics, and medical devices. The use of plating chemicals in the automotive industry has increased due to the growing demand for lightweight and fuel-efficient vehicles. Plating chemicals are used to improve the corrosion resistance and appearance of automotive parts and enhance their performance by increasing their hardness, strength, and wear resistance. In the electronics industry, plating chemicals are used for the surface finishing of printed circuit boards, connectors, and other electronic components. The demand for these chemicals is expected to grow due to the increasing demand for consumer electronics, especially in developing countries.

Chemical Surface Treatment Market: Competitive Landscape and Key Developments

Advanced Chemical Company; Atotech Deutschland; Chemetall; DOW; Elementis; Henkel; Nihon Parkerizing; Nippon Paint Co. Ltd.; NOF Corporation; and PPG Industries are among the key players operating in the chemical surface treatment market. These companies have a widespread presence worldwide, which provides lucrative opportunities to serve a large number of customers and expand the chemical surface treatment market.

Contact Us

Phone: +1-646-491-9876

Email Id: sales@theinsightpartners.com