High Temperature Insulation Materials Market: Key Insights

The high temperature insulation materials market is driven by the increasing demand for insulation materials that can withstand high temperatures in various end-use industries such as energy, chemical, and automotive. One key insight is that the energy industry is the largest end-use market for high temperature insulation materials, as the demand for insulation in power plants, oil and gas, and other energy production facilities is rising. This is due to the increasing use of high-temperature processes and equipment in the energy industry, which requires insulation materials that can withstand high temperatures.

Another key insight is that the chemical industry is a significant end-use market for high temperature insulation materials. The chemical industry requires insulation materials that can withstand high temperatures to protect equipment and personnel from heat and fire hazards.

High Temperature Insulation Materials Market

High Temperature Insulation Materials Market Size and Forecasts (2021 - 2031), Global and Regional Share, Trends, and Growth Opportunity Analysis Report Coverage: by Type (Insulating Fire Bricks, Ceramic Fibers, Calcium Silicate, and Others); Temparature Range (600-1,000°C, 1,001-1,500 °C, 1,501-1,700°C, and 1,700° & Above); and End User (Ceramics, Petrochemicals, Iron & Steel, Cement, Powder Metallurgy, and Others), and Geography (North America, Europe, Asia Pacific, and South and Central America)

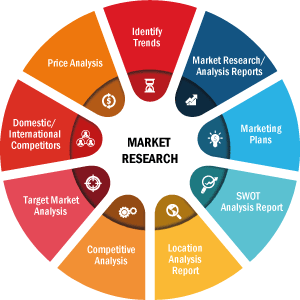

High Temperature Insulation Materials Market SWOT Analysis by 2031

Download Free Sample

Finally, the growing demand for lightweight and energy-efficient vehicles is also driving the growth of the high-temperature insulation materials market in the automotive industry. High-temperature insulation materials are used in the engine compartment, exhaust systems, and other areas of the vehicle to protect them from high temperatures and to reduce fuel consumption.

Overall, the high temperature insulation materials market is expected to grow as the demand for insulation materials that can withstand high temperatures in various end-use industries such as energy, chemical, and automotive increases.

Improving Energy-Efficiency to Drive High Temperature Insulation Materials Market

Improving energy efficiency is a major driver helping to grow the High Temperature Insulation Materials market. One way this is happening is that as industries become more focused on reducing their energy consumption and carbon footprint, there is a growing demand for insulation materials that can improve the energy efficiency of equipment and facilities. High-temperature insulation materials can help reduce heat loss and improve the overall thermal performance of equipment and facilities, leading to energy savings and cost reductions.

Another way in which improving energy efficiency is driving the growth of the High Temperature Insulation Materials market is that as the demand for renewable energy sources such as solar and wind power increases, there is a growing demand for insulation materials that can withstand high temperatures in these types of power generation facilities. High-temperature insulation materials can help to protect the equipment and facilities from the high temperatures generated during the production of renewable energy, which can improve the overall efficiency and lifespan of the equipment.

Finally, as the demand for energy-efficient vehicles increases, there is a growing demand for high-temperature insulation materials in the automotive industry. High-temperature insulation materials are used in the engine compartment, exhaust systems, and other areas of the vehicle to protect them from high temperatures and to reduce fuel consumption, which can improve the overall energy efficiency of the vehicle.

Overall, the improving energy-efficiency driver is helping to grow the High Temperature Insulation Materials market by increasing demand for insulation materials that can improve the energy efficiency of equipment and facilities in various end-use industries such as energy, chemical, and automotive.

High Temperature Insulation Materials Market: Segmental Overview

The global high temperature insulation materials market is segmented on the basis of type, temperature range, and end user. Based on type, the global high temperature insulation materials market is segmented into insulating fire bricks, ceramic fibers, calcium silicate, and others. On the basis of temperature, the high temperature insulation materials market is segmented into 600-1,000°C, 1,001-1,500 °C, 1,501-1,700°C, and 1,700° & above. Based on end-user, the high temperature insulation materials market is segmented into ceramics, petrochemicals, iron & steel, cement, powder metallurgy, and others.

Based on end-user, the iron & steel segment held the substantial share in the market. The iron & steel industry is a significant contributor to the growth of the High Temperature Insulation Materials market. The industry requires insulation materials that can withstand high temperatures to protect equipment and personnel from heat and fire hazards and improve equipment's energy efficiency. As the use of high-temperature processes and equipment in the iron & steel industry increases, and the demand for energy-efficient and sustainable processes and equipment increases, the demand for high-temperature insulation materials also increases.

High Temperature Insulation Materials Market: Competitive Landscape and Key Developments

Morgan Thermal Ceramics, Mitsubishi Plastics Inc., 3M Company, Dyson Group PLC, Almatis Gmbh, Unifrax I LLC, RHI AG, Isolite Insulating Products Co. Ltd., Luyang Energy-Saving Materials Co., Ltd., and Etex Group among the key players operating in the high temperature insulation materials market. These companies have a widespread presence worldwide, which provides lucrative opportunities to serve a large number of customers and expand the market.

Contact Us

Phone: +1-646-491-9876

Email Id: sales@theinsightpartners.com