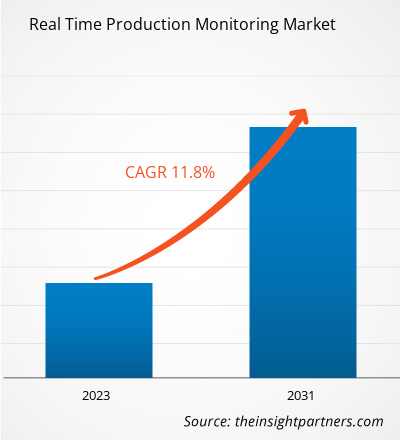

The real time production monitoring market size is projected to reach US$ 12.57 billion by 2030 from US$ 5.13 billion in 2022. The market is expected to register a CAGR of 11.8% during 2022–2030. The integration of artificial intelligence (AI) and machine learning (ML) in manufacturing processes is likely to remain a key trend in the market.

Real Time Production Monitoring Market Analysis

The market has grown steadily due to increasing demand for digital manufacturing. Digitalization in the manufacturing sector leads to the adoption of several technologies by the manufacturers as it helps manage the production process efficiently.

Real Time Production Monitoring Market Overview

Real time production monitoring is a solution that helps monitor the production process. It records all the information regarding the production performance in real time. The monitoring systems gather production data from several production line sources for the manufacturer or the operators on the production line. The collected data is then utilized to improve the production line efficiencies by gaining insights regarding the steps required to take for efficient production workflow. Several manufacturing businesses adopt these solutions of the real time production monitoring market under the industry verticals, such as automotive, chemicals, oil & gas, machinery, and food & beverages.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Real Time Production Monitoring Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Real Time Production Monitoring Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Real Time Production Monitoring Market Drivers and Opportunities

Increase in demand for Industrial Automation to Favor Market

Industrial automation uses control systems, such as robots, computers, and information technologies, to handle various machinery in an industry to replace human intervention. Depending on the operations involved, industrial automation control systems are majorly classified into two types, namely process plant automation and manufacturing automation. Industrial automation offers high product quality, reliability, and production rate while reducing production and design costs by deploying new, innovative, and integrated technologies and services. They possess various features, such as high productivity, quality, flexibility, and information accuracy, which are likely to increase the uptake of automation in the industrial sector during the forecast period. Also, the surge in the uptake of automation solutions in the oil & gas, manufacturing, chemicals & materials, pharmaceuticals, and other industries is driving the Real time production monitoring market growth.

Increase in Use of Predictive Maintenance Across Industries

With the increase in digital technologies, several manufacturing industries are leveraging predictive maintenance. These smart industries use real-time data of manufacturing assets and analyze the massive volumes of big data that sensors on the factory floor acquire. This analysis requires predictive maintenance to cut down on equipment downtime. The real-time production monitoring system can track equipment and send out alerts so that work is only done when it is actually essential. Also, these systems are frequently provided as modules to supplement enterprise resource planning (ERP) systems with preventative maintenance capabilities similar to those of a standard computerized maintenance management system (CMMS)

Real Time Production Monitoring Market Report Segmentation Analysis

Key segments that contributed to the derivation of the real time production monitoring market analysis are component, deployment, enterprise size, and industry.

- Based on component, the market is segmented by solution and services. The solution segment held a significant market share in 2022.

- Based on deployment, the market is segmented into on-premises and cloud. The cloud segment held a larger market share in 2022.

- Based on enterprise size, the market is segmented into large enterprise and SMEs. The large enterprise segment held a larger market share in 2022.

- Based on industry, the market is segmented into process manufacturing and discrete manufacturing. The process manufacturing segment held the largest share of the market in 2022.

Real Time Production Monitoring Market Share Analysis by Geography

The geographic scope of the real time production monitoring market report is mainly divided into five regions: North America, Asia Pacific, Europe, Middle East & Africa, and South & Central America.

Asia Pacific is expected to dominate the market in 2022. Asia Pacific has long been a strong manufacturing base, and the sector continues to be a strong adopter of the IoT. IoT is widely adopted across verticals across the region, leading to the adoption of digital solutions. The region has strong potential for the strength of its manufacturing sector. In March 2023, Rockwell Automation Inc. announced the outcome of the 8th annual "State of Smart Manufacturing Report." According to a survey from 1,350 manufacturers across countries such as Australia, India, China, Republic of Korea, and Japan, around 44% of manufacturers in APAC plan to adopt smart manufacturing within the next year, whereas around 80% of manufacturers in China, 60% in Australia, and 59% in India have been already using some components of smart manufacturing. Thus, the growing adoption of smart manufacturing and existing smart manufacturing facilities represent a strong real time production monitoring market share in APAC as this solution helps smart facilities manage the production workflow efficiently in real time.

Real Time Production Monitoring Market Regional Insights

The regional trends and factors influencing the Real Time Production Monitoring Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Real Time Production Monitoring Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Real Time Production Monitoring Market

Real Time Production Monitoring Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2022 | US$ 5.13 Billion |

| Market Size by 2030 | US$ 12.57 Billion |

| Global CAGR (2023 - 2031) | 11.8% |

| Historical Data | 2020-2021 |

| Forecast period | 2023-2031 |

| Segments Covered |

By Component

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

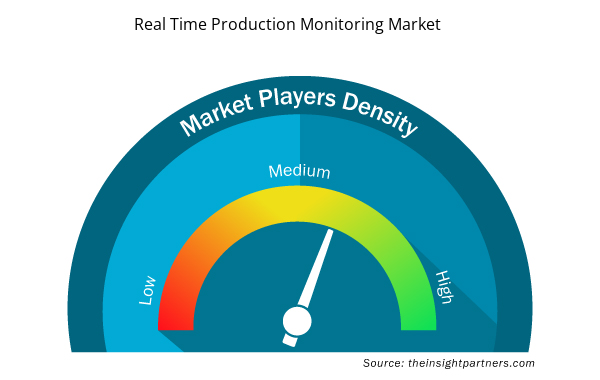

Real Time Production Monitoring Market Players Density: Understanding Its Impact on Business Dynamics

The Real Time Production Monitoring Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Real Time Production Monitoring Market are:

- Oracle

- Hitachi, Ltd.

- Rockwell Automation

- Dassault Systèmes

- Aspen Technology, Inc.

- sedApta

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Real Time Production Monitoring Market top key players overview

Real Time Production Monitoring Market News and Recent Developments

The real time production monitoring market is evaluated by gathering qualitative and quantitative data post primary and secondary research, which includes important corporate publications, association data, and databases. A few of the developments in the real time production monitoring market are listed below:

- Capgemini, a global leader in business and technology transformation services, and Schneider Electric, a leader in the digital transformation of energy management and automation, announced a new collaboration in energy optimization. Designed to help organizations accelerate their journey towards smarter and greener facility management and energy efficiency, the Energy Command Center leverages a unique end-to-end combination of digital solutions and cutting-edge technologies to both simplify energy management and optimize its consumption. (Source: CAPGEMINI, Press Release, May 2024)

- Oracle announced new generative AI capabilities within the Oracle Fusion Cloud Applications Suite that will help customers improve decision-making and enhance the employee and customer experience. The latest AI additions include new generative AI capabilities embedded in existing business workflows across finance, supply chain, HR, sales, marketing, and service, as well as an expansion of the Oracle Guided Journeys’ extensibility framework to enable customers and partners to incorporate more generative AI capabilities to support their unique industry and competitive needs. (Source: Oracle, Press Release, March 2022)

Real Time Production Monitoring Market Report Coverage and Deliverables

The “Real Time Production Monitoring Market Size and Forecast (2020–2030)” report provides a detailed analysis of the market covering below areas:

- Real Time Production Monitoring market size and forecast at global, regional, and country levels for all the key market segments covered under the scope

- Real Time Production Monitoring market trends as well as market dynamics such as drivers, restraints, and key opportunities

- Detailed PEST/Porter’s Five Forces and SWOT analysis

- Real Time Production Monitoring market analysis covering key market trends, global and regional framework, major players, regulations, and recent market developments

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments for the Real Time Production Monitoring market

- Detailed company profiles

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Component, Deployment, Enterprise Size, and Industry

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

This text is related

to country scope.

Frequently Asked Questions

Capgemini SE, Oracle Corp, Hitachi Ltd, Rockwell Automation Inc, and Siemens AG are among the leading real time production monitoring market.

The estimated value of the real time production monitoring market is expected to reach US$ 12.57 billion by 2030.

The market is expected to grow at a CAGR of 11.8% over the forecast period.

The integration of artificial intelligence (AI) and machine learning (ML) in manufacturing processes is likely to remain a key trend in the market.

Asia Pacific dominated the real time production monitoring market in 2022.

The market has grown steadily due to increasing demand for digital manufacturing. Digitalization in the manufacturing sector leads to the adoption of several technologies by the manufacturers as it helps manage the production process efficiently.

Trends and growth analysis reports related to Technology, Media and Telecommunications : READ MORE..

The List of Companies - Real Time Production Monitoring Market

- Oracle

- Hitachi, Ltd.

- Rockwell Automation

- Dassault Systèmes

- Aspen Technology, Inc.

- sedApta

- Siemens

- Capgemini

- Infosys Limited

- GE DIGITAL

Get Free Sample For

Get Free Sample For