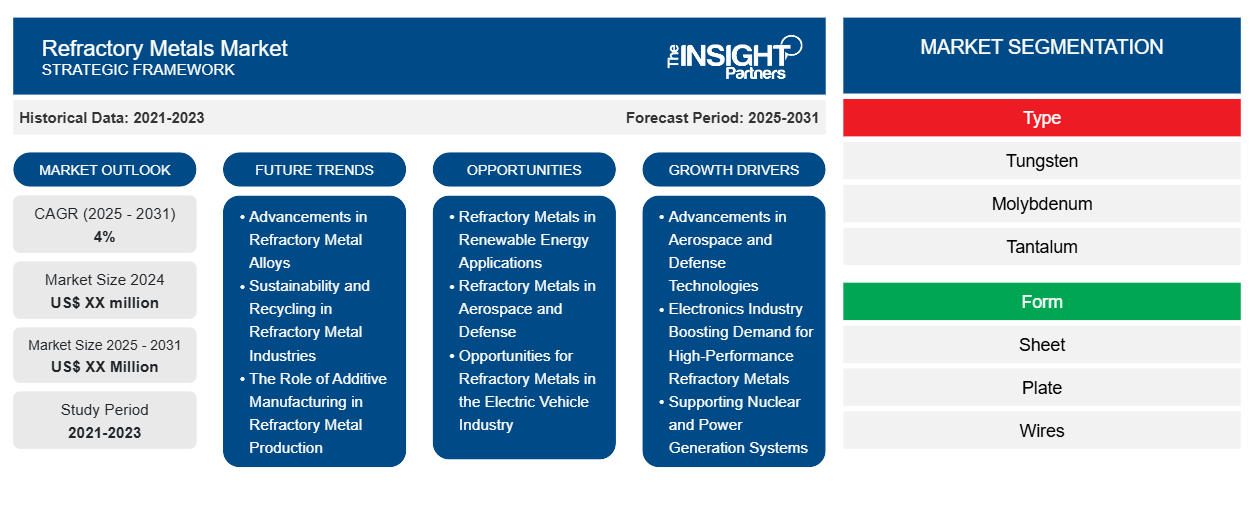

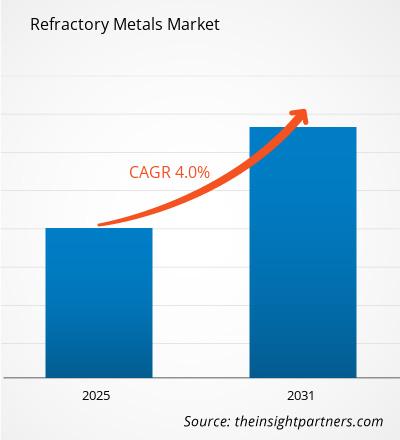

The Refractory Metals Market is expected to register a CAGR of 4% from 2025 to 2031, with a market size expanding from US$ XX million in 2024 to US$ XX Million by 2031.

The refractory metals market report is segmented by type (tungsten, molybdenum, tantalum, rhenium, niobium, and others). The market is segmented based on form (sheet, plate, wires, rods, and others). The market is segmented based on end use (aerospace and defense, electronics and semiconductors, automotive, medical, chemicals, industrial, and others). The market size and forecast at global, regional, and country levels for all the key market segments are covered under the scope. The report offers the value in USD for the above analysis, segments, regions, and countries. The report covers market trends, as well as market dynamics such as drivers, restraints, and key opportunities. The report also covers industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments in the market.

Purpose of the Report

The report Refractory Metals Market by The Insight Partners aims to describe the present landscape and future growth, top driving factors, challenges, and opportunities. This will provide insights to various business stakeholders, such as:

- Technology Providers/Manufacturers: To understand the evolving market dynamics and know the potential growth opportunities, enabling them to make informed strategic decisions.

- Investors: To conduct a comprehensive trend analysis regarding the market growth rate, market financial projections, and opportunities that exist across the value chain.

- Regulatory bodies: To regulate policies and police activities in the market with the aim of minimizing abuse, preserving investor trust and confidence, and upholding the integrity and stability of the market.

Refractory Metals Market Segmentation

Type

- Tungsten

- Molybdenum

- Tantalum

- Rhenium

- Niobium

- Others

Form

- Sheet

- Plate

- Wires

- Rods

- Others

End Use

- Aerospace and Defense

- Electronics and Semiconductors

- Automotive

- Medical

- Chemicals

- Industrial

- Others

Geography

- North America

- Europe

- Asia-Pacific

- South and Central America

- Middle East and Africa

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Refractory Metals Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Refractory Metals Market Growth Drivers

- Advancements in Aerospace and Defense Technologies: Tungsten, molybdenum, tantalum, niobium are some of the refractory metals that find application in aerospace and defense applications where they are being exploited for their high temperature resistance and ability to withstand extreme mechanical stresses. These metals find applications in aerospace in turbine engine parts, rocket propulsion systems, and all other extremely high-performance components that must operate under rapid transient and high loading. Such metals are forecasted to further increase demand due to the requirements for modernization of military defense technology as well as increasing requirements in space exploration with the proliferation of new and advanced aircraft.

- Electronics Industry Boosting Demand for High-Performance Refractory Metals: Another major quality contributor to the growth of the market for refractory metals is electronics companies. These metals are used for their extremely high melting points and their high electrical conductive ability in electronic applications such as semiconductors, capacitors, connectors, and so on. It is going to raise the requirement for advanced refractory metals in microelectronics due to high global demands for electronic devices such as smart devices, smartphones, and computers.

- Supporting Nuclear and Power Generation Systems: Refractory metals have become important resources in the energy field, especially in nuclear energy and power generation. Molybdenum, tungsten, and niobium are used in components for high-temperature applications such as reactor cores, heat exchangers, and turbines of power plants. The evolving requirement for renewable and nuclear energy systems and energy-efficient systems is expected to increase the demand for these metals used in such applications. The very ability of these metals to stand up in quite harsh environments makes them imperative in securing energy production equipment's reliability and durability.

Refractory Metals Market Future Trends

- Advancements in Refractory Metal Alloys: New development of refractory metal alloys will continue to be essential to the industry as it attempts to extend the performance boundaries. Such alloys are those which, besides from being made up of refractory metals, are also containing other materials to achieve improvements in properties like strength, ductility and resistance to corrosion and thermal effects. Research and development are expected to be geared towards alloy development, which will in turn be result-oriented towards pouring novel application areas to be availed with refractory metals' presence in aerospace, electronics, power generation, and so on. Advanced alloys will further consider the specific needs of novel applications such as additive manufacturing or 3D printing and very high-temperature environments.

- Sustainability and Recycling in Refractory Metal Industries: With environmental concerns increasing and the increasing scarcity of some refractory metals (like tungsten and tantalum), this trend is increasingly being viewed as recycling and sustainable practices throughout the industry. Recycling of refractory metals from scrap materials is proving to be a great deal more efficient in reducing the environmental dependence on mining. With evolving global sustainable practices, these companies will invest in extra sustainable methods of extraction, recycling, and usage. The result will be an efficient sustainable economy model for the market of refractory metals in terms of environmental damage from primary production.

- The Role of Additive Manufacturing in Refractory Metal Production: Additive production or formation is increasingly being adopted to manufacture sophisticated three-dimensional components, which were difficult, if not possible, or very costly to produce from conventional methods. Refractory metals, such as tungsten and molybdenum, are used with 3D printing technologies for making highly specialized parts in aerospace, automotive, and electronics industries. It is expected to boost market demand for these materials in the future to print custom, high-performance components directly from refractory metals.

Refractory Metals Market Opportunities

- Refractory Metals in Renewable Energy Applications: Refractory metals should ideally play an important role in renewable energy, particularly solar energy, wind energy, and hydrogen fuel cells; their high temperature capability and corrosion resistance makes them fit for the most demanding environments of renewable energy production. This is likely to uncover emerging markets as the world turns to sustainable energy sources.

- Refractory Metals in Aerospace and Defense: With the continuous demand for refractories being supplied in the aerospace and defense industries, such demand will continue to soar higher as the various designs offer low weight, making it a strong need for higher levels of lightweight, heat-resistant materials for aircraft, spacecraft, and missile systems. This will definitely give rise to the application of advanced materials in propulsion systems, turbines, and even heat shields, bringing opportunities for refractory metal producers. The expansion of space and the advancement into the next-generation fighter planes and commercial planes will keep refractory metal in high demand for the long haul.

- Opportunities for Refractory Metals in the Electric Vehicle Industry: The growth of electric vehicles or EVs creates new opportunities for the refractory metals industry in a future market for high-performance components such as batteries, electrical connectors, and heat management systems. Tungsten and molybdenum are the new refractory metals for production parts for electric vehicles because they have very rich endurance power under high temperatures with enhanced performance and longevity features in critical vehicle components. As the electric vehicles market increases, demand for high-performance advanced refractory materials in the manufacture of electric vehicles will also increase.

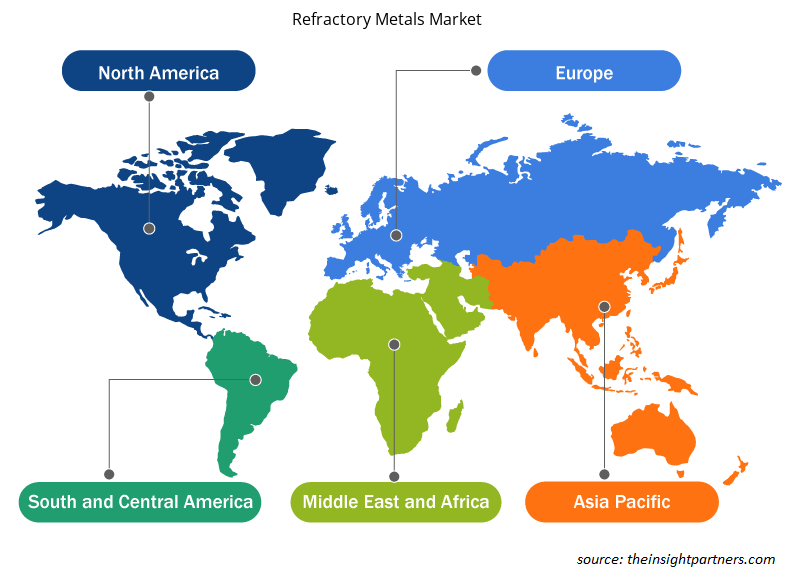

Refractory Metals Market Regional Insights

The regional trends and factors influencing the Refractory Metals Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Refractory Metals Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Refractory Metals Market

Refractory Metals Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ XX million |

| Market Size by 2031 | US$ XX Million |

| Global CAGR (2025 - 2031) | 4% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

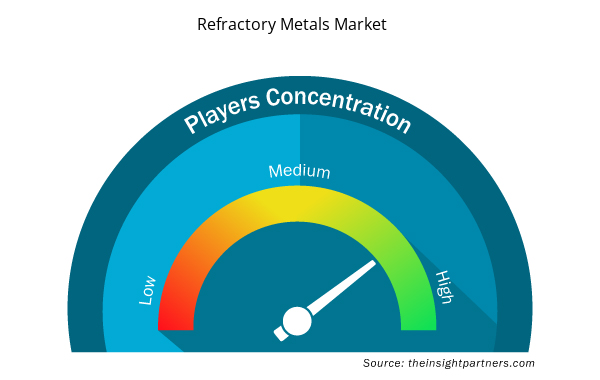

Refractory Metals Market Players Density: Understanding Its Impact on Business Dynamics

The Refractory Metals Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Refractory Metals Market are:

- A.L.M.T. Corp.

- CBMM (COMPANHIA BRASILEIRA DE METALURGIA E MINERAÇÃO)

- China Molybdenum Co., Ltd.

- Global Advanced Metals Pty Ltd

- Global Tungsten & Powders Corp.

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Refractory Metals Market top key players overview

Key Selling Points

- Comprehensive Coverage: The report comprehensively covers the analysis of products, services, types, and end users of the Refractory Metals Market, providing a holistic landscape.

- Expert Analysis: The report is compiled based on the in-depth understanding of industry experts and analysts.

- Up-to-date Information: The report assures business relevance due to its coverage of recent information and data trends.

- Customization Options: This report can be customized to cater to specific client requirements and suit the business strategies aptly.

The research report on the Refractory Metals Market can, therefore, help spearhead the trail of decoding and understanding the industry scenario and growth prospects. Although there can be a few valid concerns, the overall benefits of this report tend to outweigh the disadvantages.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

This text is related

to segments covered.

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

This text is related

to country scope.

Frequently Asked Questions

Based on geography, Asia Pacific held the largest share of the refractory metals market due to the strong growth of the automotive and industrial sector in the region.

Advancements in alloy development are expected to be the key market trends.

Based on end use, the automotive segment is expected to witness the fastest growth during the forecast period.

The Refractory Metals Market is estimated to witness a CAGR of 4% from 2023 to 2031

Increasing demand in aerospace and defense are driving the market growth.

Elmet Technologies, QSIL SE, Plansee SE, Ultramet, Cleveland Tungsten Inc, GTP, H.C. Starck Tungsten GmbH, Kennametal Inc, Hyperion Materials and Technologies Inc, and Rhenium Alloys Inc are the key players operating in the refractory metals market.

Trends and growth analysis reports related to Chemicals and Materials : READ MORE..

The List of Companies

- A.L.M.T. Corp.

- CBMM (COMPANHIA BRASILEIRA DE METALURGIA E MINERAÇÃO)

- China Molybdenum Co., Ltd.

- Global Advanced Metals Pty Ltd

- Global Tungsten & Powders Corp.

- H.C. Starck GmbH

- Ningxia Orient Tantalum Industry Co. Ltd (OTIC)

- Plansee SE

- Rhenium Alloys, Inc.

- Tejing Tungsten, Inc.

Get Free Sample For

Get Free Sample For