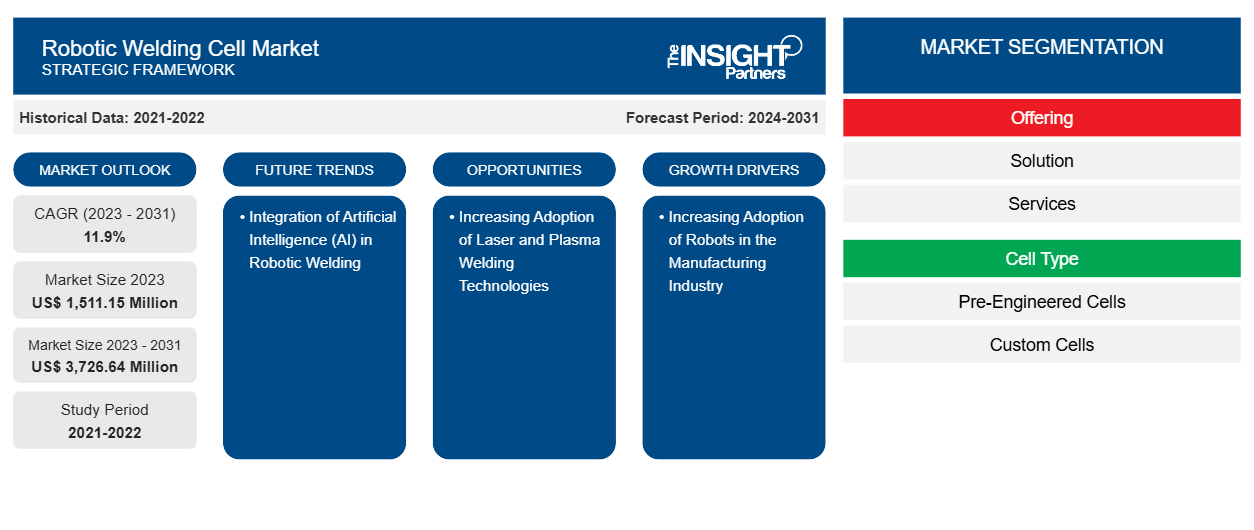

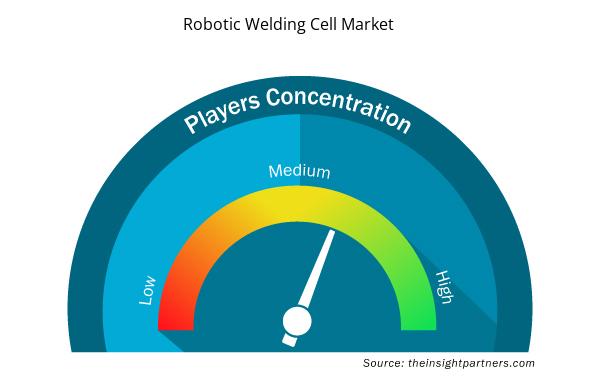

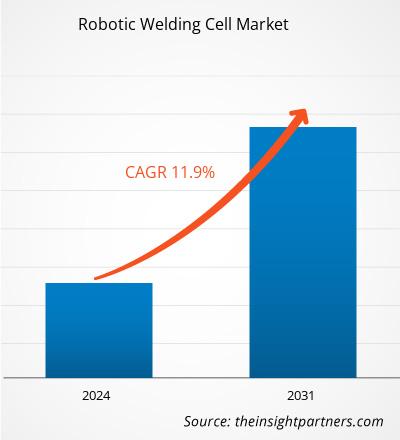

The robotic welding cell market size is projected to reach US$ 3,726.64 million by 2031 from US$ 1,511.15 million in 2023. The market is expected to register a CAGR of 11.9% during 2023–2031. The increasing adoption of Industry 4.0 technologies is likely to bring new key trends in the market in the coming years.

Robotic Welding Cell Market Analysis

A robotic welding cell consists of several components that work together to weld parts. Robot welding cells provide world-class welding operations and are designed as per global standards to save operator costs and time. Pre-engineered cells are cost-efficient robotic welding cells and include only the basic essential components required for the welding processes. This basic structure of the cells can be quickly installed; it allows manufacturers to reduce cell production time and deliver the final product at the earliest. Custom cells are expensive compared to pre-engineered cells as they include unique equipment along with basic essential components. These are mainly manufactured according to the client's specific interests. Thus, the time required to manufacture and deliver a custom robotic welding cell is higher than that of a pre-engineered cell. Welding robots are widely used in the automotive industry. The demand for vehicles is increasing notably. The rising consumer expenditure is one of the factors that is driving the demand for vehicles across the globe, especially in Asian countries. As per the data published by the International Organization of Motor Vehicle Manufacturers in 2024, the overall vehicle production reached 93 million in 2023, a 12% increase from 2021 to 2023. The rise in the construction of new facilities has led to increased demand for welding robots in these new automotive facilities, ultimately driving the robotic welding cells market.

Robotic Welding Cell Market Overview

The major stakeholders in the global robotic welding cell market ecosystem include raw material/component providers, robotic welding cell manufacturers, government organizations, regulatory bodies, and end customers. Component and hardware providers provide various components and parts to robotic welding cell manufacturers. The key robotic welding cell manufacturers included in this report are Abb Ltd, Acieta LLC, Carl Cloos Schweisstechnik Gmbh, Kawasaki Heavy Industries, Ltd; Kuka AG; Phoenix Industrial Solutions; The Lincoln Electric Company; Wec Group Ltd.; and Yaskawa America, Inc.; among others. After the robotic welding cell manufacturers, there are several peripheral stakeholders in the global robotic welding cell market, which play a crucial role in enabling the technological advancements and adoption of robotic welding cells.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Robotic Welding Cell Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Robotic Welding Cell Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Robotic Welding Cell Market Drivers and Opportunities

Increasing Adoption of Robots in Manufacturing Industry

Robots play an important role in the manufacturing industry. Robots help increase overall efficiency and productivity in production operations. They are being used in the manufacturing industry for various applications such as assembly & dispensing, handling & picking, machining & cutting, welding & soldering, casting & molding, finishing & sanding, painting & coating, cleaning & hygiene, logistics & storage, and packing & palletizing. As per the data published by the International Federation of Robots in 2024, approximately 4.2 million robots were operating in factories across the globe in 2023, an increase from 3.9 million in 2022. As stated by the International Federation of Robots in 2021, half of the total robots working in factories will be used for welding applications. Thus, the increasing adoption of robots in the manufacturing industry is propelling the robotic welding cell market growth.

Increasing Adoption of Laser and Plasma Welding Technologies

The demand for laser welding is increasing rapidly. Laser welding technology uses high-energy laser beams developed using carbon dioxide, nitrogen, and helium. This helps in joining the materials with high precision and speed. The popularity of laser welding is increasing owing to minimal distortions and the ability to weld different materials. In addition, by improving the laser efficiency and optimizing the welding process, overall energy conservation can be achieved with this type of welding technology. This is one of the important factors that is increasing the demand for laser welding, as reducing energy consumption is one of the main concerns across the globe.

Further, when integrated with advanced technologies such as AI and ML, this welding technology can perform efficiently. Thus, the demand for laser welding technology is increasing notably. Similarly, plasma welding technology offers various advantages, including high power density, clean and smooth welds, high welding speed, low distortion, and improved gap bridging. The welds produced through plasma welding are very strong and less visible.

Robotic Welding Cell Market Report Segmentation Analysis

Key segments that contributed to the derivation of the robotic welding cell market analysis are offering, cell type, and end-use industry.

- Based on offering, the global robotic welding cell market is bifurcated into solutions and services. The solutions segment accounted for a larger market share in 2023 and is expected to register a higher CAGR during the forecast period. Robotic welding cell solutions help manufacturers achieve their additional production capacity and mitigate labor shortage problems. Such advantages of robotic welding cells over manual welding processes are driving the demand for robotic welding cells.

- Based on cell type, the global robotic welding cell market is segmented into pre-engineered cells and custom cells. The pre-engineered cells segment dominated the cell type segment with a market share of 68.3% in 2023, and the custom cells segment is estimated to register a higher CAGR during the forecast period. Pre-engineered robotic welding cells are standard robotic welding cells that have a larger workspace with a longer robot manipulator and two larger tabletops. On the other hand, custom cells are manufactured according to the end user's requirements and are customized for specific industries.

- Based on end-use industry, the global robotic welding cell market is segmented into automotive, manufacturing, and aerospace and defense. The automotive segment accounted for the second largest share of the market and is projected to register the highest growth rate during the forecast period. One of the factors driving the demand from the automotive industry is the increasing production and sales of vehicles across the globe. The manufacturing industry is anticipated to register a notable CAGR during the forecast period. One of the factors driving the demand for robotic welding cells in the manufacturing segment is the increasing industrialization trend across the globe, especially in developing countries.

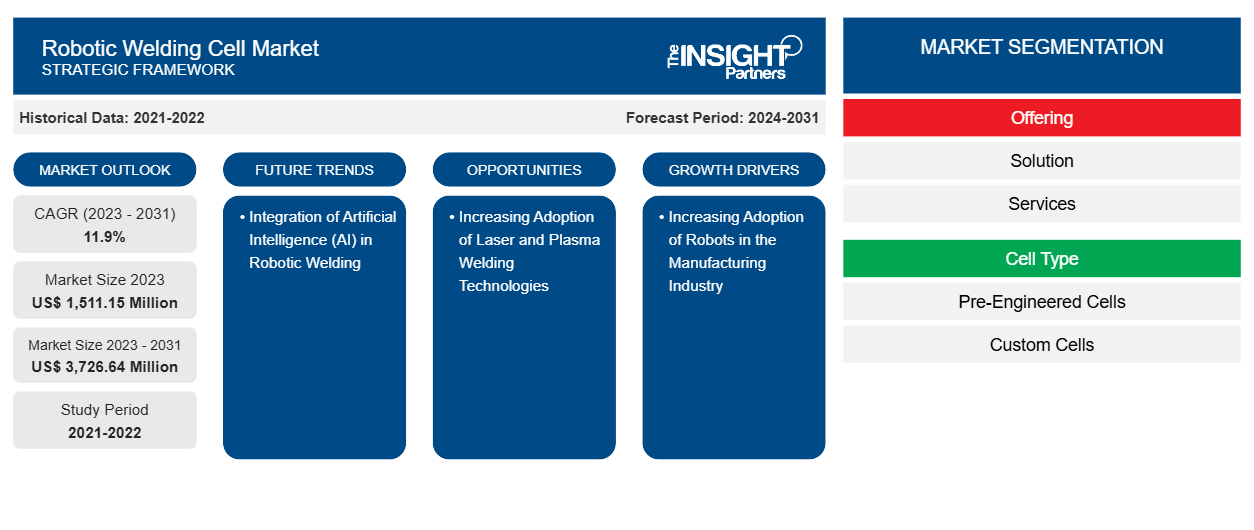

Robotic Welding Cell Market Share Analysis

The geographic scope of the robotic welding cell market report offers a detailed regional and country analysis. North America, Europe, and Asia Pacific are major regions witnessing significant growth in the robotic welding cell market. China accounted for almost 60% of the market share in the total number of robot installations in 2022. China installed ~0.2 million robots in 2022, whereas Japan installed more than 50,000 units in 2022, the second largest market globally. Apart from China and Japan, Singapore, India, and Thailand are a few of the major markets in Asia Pacific.

Europe accounted for the second largest market share in industrial robot installations and the robotic welding cell industry. Germany was the largest market in Europe for robotic welding cells and industrial robots in 2023. One of the factors driving the demand for robotic welding cells is the focus on increasing the adoption of Industry 4.0 technologies in Germany. Germany, France, the UK, and Italy are some of the notable share in the robotic welding cells market.

North America is one of the notable markets for robotic welding cells owing to the presence of a few significant manufacturing companies across industries, increased need for Industry 4.0, and rise in demand for advanced technology. The US accounted for the largest share of the market owing to industrialization and digitalization trends in the country. In addition, the US is home to a few major automotive and aerospace manufacturing companies, such as Tesla, Boeing, and Ford Motors.

Robotic Welding Cell Market Regional Insights

The regional trends and factors influencing the Robotic Welding Cell Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Robotic Welding Cell Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Robotic Welding Cell Market

Robotic Welding Cell Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2023 | US$ 1,511.15 Million |

| Market Size by 2031 | US$ 3,726.64 Million |

| Global CAGR (2023 - 2031) | 11.9% |

| Historical Data | 2021-2022 |

| Forecast period | 2024-2031 |

| Segments Covered |

By Offering

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

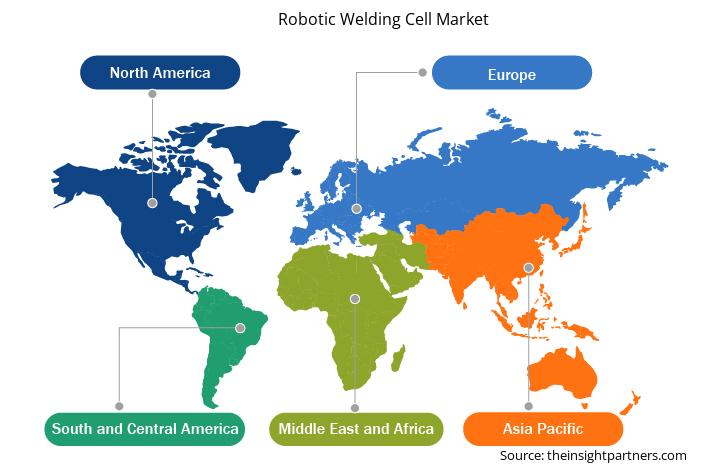

Robotic Welding Cell Market Players Density: Understanding Its Impact on Business Dynamics

The Robotic Welding Cell Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Robotic Welding Cell Market are:

- ABB Ltd.

- Acieta

- Carl Cloos Schweisstechnik GmbH

- Lincoln Electric Holdings Inc.

- Kuka AG

- Kawasaki Heavy Industries Ltd.

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Robotic Welding Cell Market top key players overview

Robotic Welding Cell Market News and Recent Developments

The robotic welding cell market is evaluated by gathering qualitative and quantitative data post primary and secondary research, which includes important corporate publications, association data, and databases. A few of the developments in the robotic welding cell market are listed below:

- ABB's new OmniVance FlexArc Compact cell saves space and adds flexibility to welding applications. ABB Ltd. launched its OmniVance FlexArc Compact - a new, smaller welding application cell with greater flexibility, ease of use, and better integration to help businesses address labor shortages in welding. The OmniVance FlexArc Compact is the smallest arc welding cell in its class. Its innovative 45-degree gantry robot mount design maximizes the robot's working parameters by placing it in the center of a three-axis turntable, bringing it closer to the workpiece. (ABB Ltd., Company Website, June 2022)

Robotic Welding Cell Market Report Coverage and Deliverables

The "Robotic Welding Cell Market Size and Forecast (2021–2031)" report provides a detailed analysis of the market covering below areas:

- Robotic welding cell market size and forecast at country levels for all the key market segments covered under the scope

- Robotic welding cell market trends, as well as market dynamics such as drivers, restraints, and key opportunities

- Detailed PEST and SWOT analysis

- Robotic welding cell market analysis covering key market trends, country framework, major players, regulations, and recent market developments

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments for the robotic welding cell market

- Detailed company profiles

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Offering, Cell Type, End-use Industry

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

Argentina, Australia, Brazil, Canada, China, France, Germany, India, Italy, Japan, Mexico, Russian Federation, Saudi Arabia, South Africa, South Korea, United Arab Emirates, United Kingdom, United States

Frequently Asked Questions

Rising integration of artificial Intelligence (AI) in robotic welding is major trend in the market. Artificial intelligence (AI) and machine learning (ML) are being adopted in almost all industries, including the welding industry. By leveraging AI, welding systems can be made smarter and adaptable. Some of the key areas where AI integration is beneficial are weld defect detection, adaptive welding, and path planning. One of the key factors in the welding process is ensuring quality control. Defects in the welded area lead to high risks in the overall strength and safety of the final product. Integration of AI and ML, along with advanced vision systems, can be used for defect detection in real-time. This technology can be used to detect various types of defects, such as cracks, incomplete welding, and porosity. In addition, as this technology continuously gathers data from the system in real-time, AI and ML can learn and improve the process by analysing real-time and historical data.

The robotic welding cell market was valued at US$ 1,511.15 million in 2023 and is projected to reach US$ 3,726.64 million by 2031; it is expected to register a CAGR of 11.9% during 2023–2031.

The demand for robotics across the globe is growing notably owing to factors such as digitalization, rising trends of automation, increased need for higher efficiency, and availability of innovative technology. These are some of the factors that are driving the demand for industrial robots, ultimately robotic welding cells across the globe. According to the data provided in the World Robotics Report 2023, 0.55 million industrial robots were installed worldwide in 2022.

The key players operating in the robotic welding cell market include Abb Ltd, Acieta LLC, Carl Cloos Schweisstechnik Gmbh, Kawasaki Heavy Industries, Ltd; Kuka AG; Phoenix Industrial Solutions; The Lincoln Electric Company; Wec Group Ltd.; Yaskawa America, Inc.; among others.

Asia Pacific is anticipated to have largest share in robotic welding cell market.

The solution segment led the robotic welding cell market with a significant share in 2023.

The robotic welding cell market is expected to reach US$ 3,726.64 million by 2031.

Trends and growth analysis reports related to Manufacturing and Construction : READ MORE..

The List of Companies - Robotic Welding Cell Market

- ABB Ltd.

- Acieta

- Carl Cloos Schweisstechnik GmbH

- Lincoln Electric Holdings Inc.

- Kuka AG

- Kawasaki Heavy Industries Ltd.

- Phoenix Industrial Solutions

- WEC Group Ltd.

- Yaskawa America Inc

- Zeman Bauelemente Produktionsgesellschaft GmbH

- Fanuc Corp.

- Fronius International GmbH

- ESABB

- OTC-DAIHEN

- Kemppi Oy

- Panasonic Holdings Corp.

- Universal Robots AS.

Get Free Sample For

Get Free Sample For