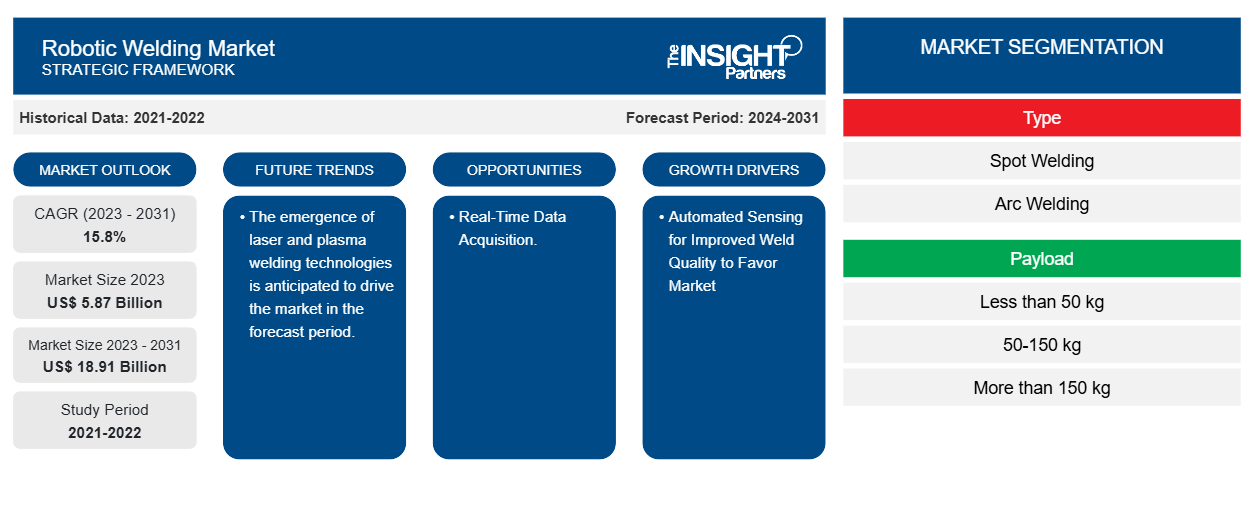

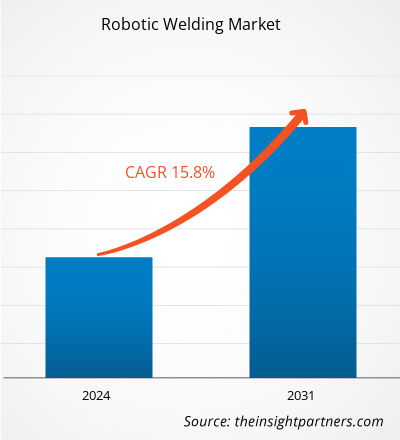

The robotic welding market size is projected to reach US$ 18.91 billion by 2031 from US$ 5.87 billion in 2023. The market is expected to register a CAGR of 15.8% during 2023–2031. Industrial 4.0 to drive demand for industrial robots and increasing adoption of welding robots in automotive industries are likely to be the key drivers and trends of the market.

Robotic Welding Market Analysis

The robotic welding market is experiencing significant growth globally. This growth is attributed to the Industrial 4.0 to drive demand for industrial robots and the increasing adoption of welding robots in automotive industries. Moreover, the government initiatives to support digital transformation in APAC and the emergence of laser and plasma welding technologies are among other factors bolstering the growth of the robotic welding market.

Robotic Welding Market Overview

Robotic welding is a method that helps the industrial sector automate its processes, increase accuracy, reduce lead time, and enhance safety. The robot welding process is considered to be the highest productive when it is implemented for high-volume and repetitive tasks. There are multiple types of robotic welding processes.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Robotic Welding Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Robotic Welding Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Robotic Welding Market Drivers and Opportunities

Automated Sensing for Improved Weld Quality to Favor Market

Automated sensing technologies allow robotic welders to adopt operations according to individual workpiece dimensions. This upgrades the quality of each weld while raising the speed of operations and, as a result, provides for higher throughput. Including these technologies in each weld cell helps to Monitor the weld operation and record the details for continuous process optimization, automatically adjust the weld robot’s parameters according to the workpiece monitor the weld operation, and record the details for continuous process optimization.

Real-Time Data Acquisition

Along with automated sensing, the operational data acquisition and analysis of robotic welding systems are advancing at a rapid speed. As each weld needs a specific inspection to qualify the quality control process, these tools make it possible to prove the joint strength, seal of every seam, and weld penetration during the weld operation.

Arc tracking control systems can automatically identify faults and correct the weld operation to minimize rework that usually only surfaces during a secondary inspection. Additionally, these systems provide for Joint width and profile measurement during weld operation, joint edge detection, and tracking seam penetration during welds, controlling weld penetration according to the specifications.

Robotic Welding Market Report Segmentation Analysis

Key segments that contributed to the derivation of the robotic welding market analysis are type, payload, and end user.

- Based on type, the robotic welding market is divided into spot welding, arc welding, and others. The power management components segment is anticipated to hold a significant market share in the forecast period.

- Based on payload, the robotic welding market is divided into less than 50 kg, 50-150 kg, and more than 150 kg. The less than 50 kg segment is anticipated to hold a significant market share in the forecast period.

- By end user, the market is segmented into automotive and transportation, electrical and electronics, metal and machinery, and construction. Automotive and transportation are anticipated to hold a significant market share in the forecast period.

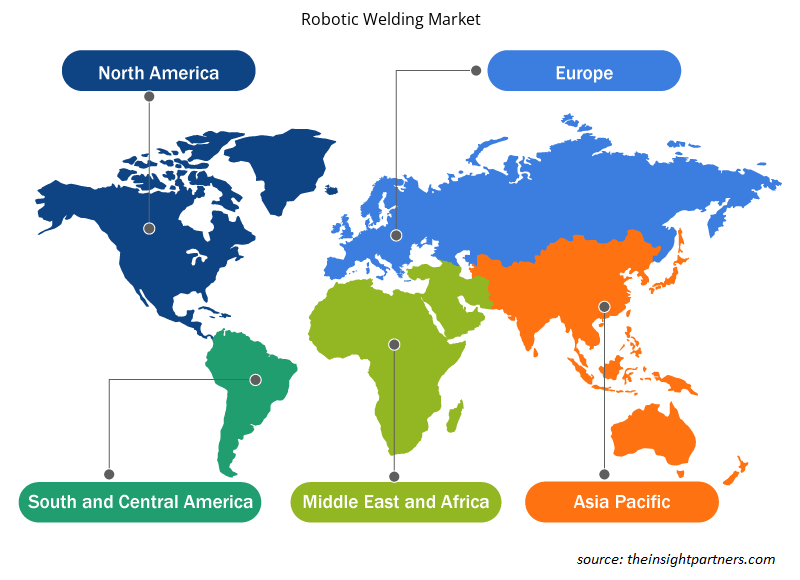

Robotic Welding Market Share Analysis by Geography

The geographic scope of the robotic welding market report is mainly divided into five regions: North America, Asia Pacific, Europe, Middle East & Africa, and South & Central America.

North America has dominated the robotic welding market. High technology adoption trends in various industries in the North American region have fuelled the growth of the robotic welding market. Factors such as increased adoption of digital tools and high technological spending by government agencies are expected to drive the North American robotic welding market growth. Moreover, a strong emphasis on research and development in the developed economies of the US and Canada is forcing the North American players to bring technologically advanced solutions into the market. In addition, the US has a large number of robotic welding market players who have been increasingly focusing on developing innovative solutions. All these factors contribute to the region's growth of the robotic welding market.

Robotic Welding Market Regional Insights

The regional trends and factors influencing the Robotic Welding Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Robotic Welding Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Robotic Welding Market

Robotic Welding Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2023 | US$ 5.87 Billion |

| Market Size by 2031 | US$ 18.91 Billion |

| Global CAGR (2023 - 2031) | 15.8% |

| Historical Data | 2021-2022 |

| Forecast period | 2024-2031 |

| Segments Covered |

By Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

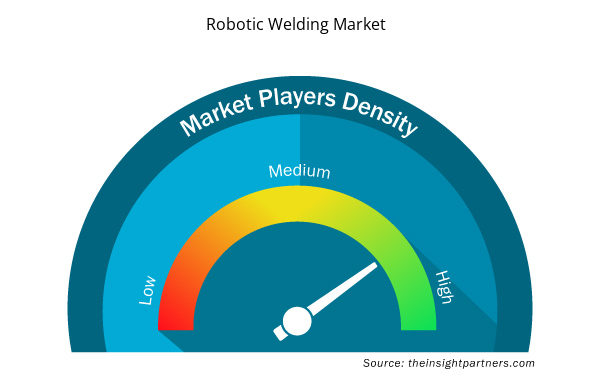

Robotic Welding Market Players Density: Understanding Its Impact on Business Dynamics

The Robotic Welding Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Robotic Welding Market are:

- Panasonic Corporation

- Yaskawa Electric Corporation

- ABB

- Fanuc Corporation

- IGM ROBOTERSYSTEME

- Kawasaki Heavy Industries, Ltd

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Robotic Welding Market top key players overview

Robotic Welding Market News and Recent Developments

The robotic welding market is evaluated by gathering qualitative and quantitative data post primary and secondary research, which includes important corporate publications, association data, and databases. A few of the developments in the robotic welding market are listed below:

- Kemppi launched a new robotic welding machine, AX MIG Welder. Introducing the Kemppi AX MIG Welder – a powerful robotic welder with seamless integration, an easy-to-use interface, and the latest welding technology. The AX MIG Welder was purpose-built for high-intensity, 24/7 automated welding environments. With 400 or 500 A power and a robotic wire feeder, it is engineered to perform difficult tasks and meet demanding production targets. (Source: Kemppi Company Website, April 2023)

- NS ARC, the largest dedicated women-owned welding wire brand in the U.S., and CLOOS North America, a pioneer in robotic welding technology with over 100 years in the industry, proudly announce their strategic alliance. (Source: NS ARC Company Website, July 2024)

Robotic Welding Market Report Coverage and Deliverables

The “Robotic Welding Market Size and Forecast (2021–2031)” report provides a detailed analysis of the market covering below areas:

- Robotic welding market size and forecast at global, regional, and country levels for all the key market segments covered under the scope.

- Robotic welding market trends as well as market dynamics such as drivers, restraints, and key opportunities.

- Detailed PEST/Porter’s Five Forces and SWOT analysis.

- Robotic welding market analysis covering key market trends, global and regional framework, major players, regulations, and recent market developments.

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments in the robotic welding market.

- Detailed company profiles.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

- Health Economics and Outcome Research (HEOR) Services Market

- Lyophilization Services for Biopharmaceuticals Market

- Joint Pain Injection Market

- Single-Use Negative Pressure Wound Therapy Devices Market

- Medical and Research Grade Collagen Market

- Skin Graft Market

- Sterilization Services Market

- Procedure Trays Market

- Bioremediation Technology and Services Market

- Skin Tightening Market

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Type, Payload, and End User

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

Brazil, Canada, China, France, Germany, India, Italy, Japan, Mexico, South Korea, Spain, United Arab Emirates, United Kingdom, United States

Frequently Asked Questions

The expected CAGR of the robotic welding market is 15.8%.

The global robotic welding market is expected to reach US$ 18.91 billion by 2031.

The key players holding majority shares in the global robotic welding market are Panasonic Corporation, Yaskawa Electric Corporation, ABB, Fanuc Corporation, IGM Robotersysteme, Kawasaki Heavy Industries, Ltd, Kuka Ag, Nachi Fujikoshi Corp, Novarc Technology, OTC Daihen.

The emergence of laser and plasma welding technologies is anticipated to drive the market in the forecast period.

Industrial 4.0 to drive demand for industrial robots and increasing adoption of welding robots in automotive industries are some of the factors driving the robotic welding market.

North America is anticipated to dominate the robotic welding market in 2023.

Get Free Sample For

Get Free Sample For