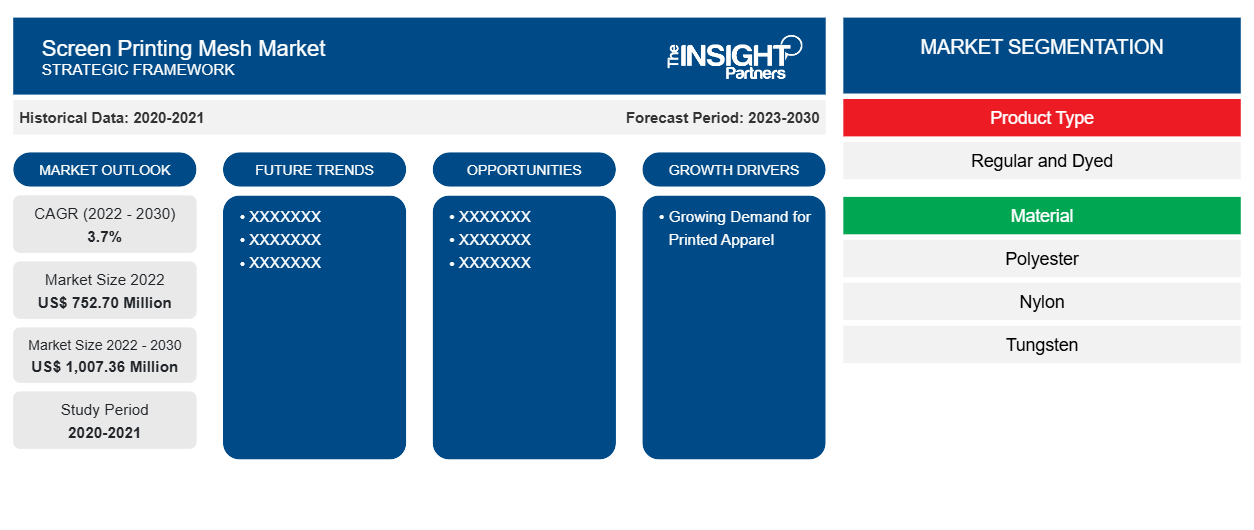

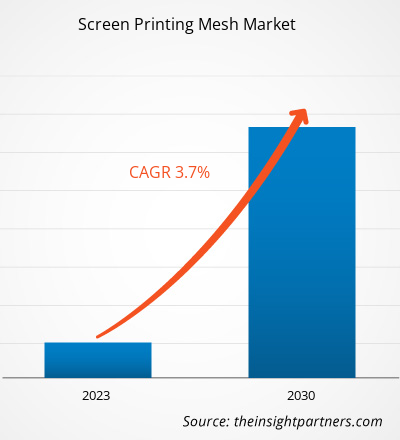

[Research Report] The screen printing mesh market size is expected to grow from US$ 752.70 million in 2022 to US$ 1,007.36 million by 2030; it is estimated to register a CAGR of 3.7% from 2022 to 2030.

Market Insights and Analyst View:

Screen printing mesh refers to the woven fabric or material that is stretched tightly over a frame to create a screen for screen printing. Screen printing mesh comes in different mesh counts. Screen printing meshes of different mesh sizes offer specific advantages during the screen printing process. They are made from materials such as nylon, polyester, stainless steel, tungsten, and others. Polyester screen printing mesh is a widely used material due to its exceptional versatility and durability. Screen printing meshes are used in textiles, electronics & electricals, glass, ceramics, and many other industries. In the electronics & electricals industry, screen printing mesh is used to print on a variety of substrates, such as circuit boards, solar panels, flexible circuits, and displays. There has been a growing demand for personalized and customized clothing, with consumers seeking unique and individualized items that reflect their personal style. This factor is significantly driving the global screen printing mesh market growth.

Growth Drivers and Challenges:

The increasing trend of printed clothing is driving the demand for screen printing mesh in the apparel industry. In recent years, there has been a growing trend toward printed clothing, with consumers seeking unique and individualized items that reflect their style. This trend has propelled the demand for screen printing mesh in the apparel industry, as it allows for high-quality and precise printing of custom designs onto a wide range of fabrics and materials. Furthermore, promotional products are becoming increasingly popular as businesses seek cost-effective ways to promote their brand. Screen printing mesh is a key component in creating high-quality and eye-catching promotional items. Many businesses and organizations use custom-printed items, such as t-shirts, bags, and hats, to promote their brand or message. Screen printing mesh allows for high-quality and cost-effective printing of these promotional products in bulk quantities. As more companies turn to promotional products as a marketing strategy, the demand for screen printing mesh will continue to increase. However, technological advancements in the printing industry may pose a challenge to the further expansion of the screen printing mesh market despite its growth potential. As digital printing technologies continue to improve, they offer a viable alternative to screen printing mesh for many applications. Digital printing allows for faster turnaround times, greater flexibility in design, and the ability to print on a wider range of materials. This factor hinders the demand for screen printing mesh.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Screen Printing Mesh Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Screen Printing Mesh Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Report Segmentation and Scope:

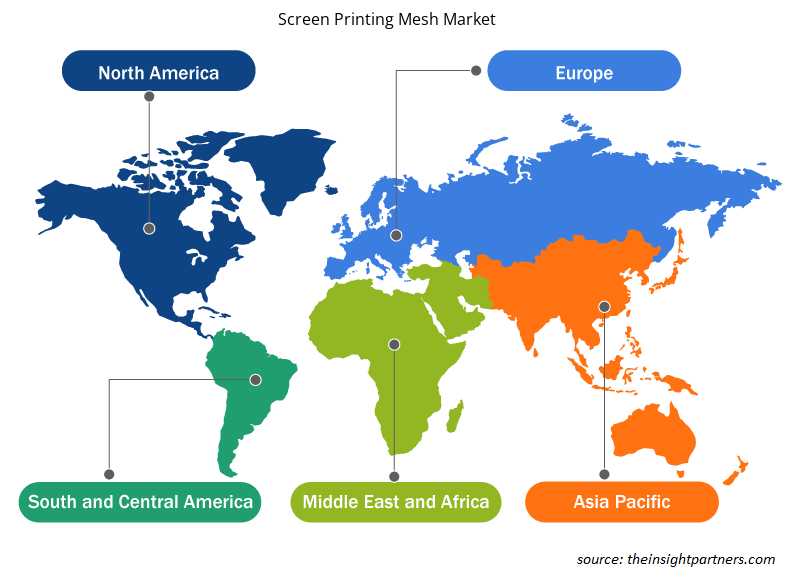

The “Global Screen Printing Mesh Market” is segmented on the basis of product type, material and application. Based on product type, the screen printing mesh market is segmented into regular and dyed. Based on material, the screen printing mesh market is segmented into polyester, nylon, tungsten, stainless steel, and others. Based on application, the screen printing mesh market is segmented into textiles, electronics and electricals, glass and ceramics, and others. Geographically, the market is segmented into North America (the US, Canada, and Mexico), Europe (Germany, France, Italy, the UK, Russia, and the Rest of Europe), Asia Pacific (Australia, China, Japan, India, South Korea, and the Rest of Asia Pacific), the Middle East & Africa (South Africa, Saudi Arabia, the UAE, and the Rest of Middle East & Africa), and South & Central America (Brazil, Argentina, and the Rest of South & Central America).

Segmental Analysis:

Based on product type, the screen printing mesh market is segmented into regular and dyed. The regular segment held a larger market share in 2022. Regular screen printing mesh is a fundamental and often underestimated component in printing and textile production. Printing mesh crafted from premium materials such as polyester and nylon serves as the unassuming canvas upon which intricate designs and patterns are expressed. Its significance lies in its ability to act as a blank slate, ensuring that the colors and details of the final print remain true to the original artwork. Based on material, the screen printing mesh market is segmented into polyester, nylon, tungsten, stainless steel, and others. The screen printing mesh market share for the polyester segment was notable in 2022. Polyester screen printing mesh is a vital and widely used material in screen printing, appreciated for its exceptional versatility and durability. Polyester, a synthetic polymer, serves as the foundation for this mesh, and its inherent qualities make it an ideal choice for a wide range of printing applications. One of the standout characteristics of polyester screen printing mesh is its strength and resilience. Based on application, the screen printing mesh market is segmented into textiles, electronics and electricals, glass and ceramics, and others. The screen printing mesh market share for the textiles segment was notable in 2022. Screen printing mesh has become an essential tool in the textile industry, offering a range of benefits that make it an ideal choice for printing designs onto fabrics. The mesh is made from a high-quality material that is durable and flexible, allowing it to be stretched over a frame without losing its shape or integrity. This makes it easy to create a smooth and even surface for printing, ensuring that every design detail is captured accurately. One of the key advantages of screen printing mesh is its ability to produce precise and detailed designs, even on complex patterns or fabrics.

Regional Analysis:

The screen printing mesh market is segmented into five key regions—North America, Europe, Asia Pacific, South & Central America, and the Middle East & Africa. Asia Pacific dominated the global screen printing mesh market, and the regional market accounted for approximately US$ 300 million in 2022. North America is also a major contributor, holding a significant portion of the global screen printing mesh market share. The North America market is expected to reach over US$ 250 million in 2030. Europe is expected to register a considerable CAGR of over 3% from 2022 to 2030. The Asia Pacific screen printing mesh market, by country, is segmented into Australia, China, India, Japan, South Korea, and the Rest of Asia Pacific. The market is driven by factors such as the growing demand for printed apparel and rising popularity of promotional products. The demand for screen printing mesh in Asia Pacific is connected to the industrialization and textile production growth in the region. Under the Sustainable Development Goals 2030, the Asian Development Bank has planned to build resilient infrastructure, promote inclusive and sustainable industrialization, and foster innovation in Asia Pacific. Asia Pacific is the main hub for textile industry. Asia Pacific consists of countries such as China, India, and Bangladesh—major producers of textile. The rise in the number of textile manufacturers in countries such as China, India, Vietnam, and Bangladesh further fuels the need for screen printing mesh.

Industry Developments and Future Opportunities:

Various initiatives taken by the key players operating in the screen printing mesh market are listed below:

- In March 2022, Sefar enlarged its SEFAR PME screen printing mesh range. These new meshes were shown at FESPA 2022. The new Sefar Open Mesh fabrics are SEFAR PME 59/150-48Y PW and SEFAR PME 75/190-40W/Y PW.

COVID-19 Impact:

The COVID-19 pandemic affected almost all industries in various countries. Lockdowns, travel restrictions, and business shutdowns in North America, Europe, Asia Pacific (APAC), South & Central America (SAM), and the Middle East & Africa (MEA) hampered the growth of several industries, including the chemicals & materials industry. The shutdown of manufacturing units disturbed global supply chains, manufacturing activities, delivery schedules, and essential and nonessential product sales. Various companies reported delays in product deliveries and a slump in their product sales in 2020. Due to the pandemic-induced economic recession, consumers became cautious and selective in purchasing decisions. Consumers significantly reduced nonessential purchases due to lower incomes and uncertain earning prospects, especially in developing regions. Many manufacturers of screen printing mesh faced declining profits due to reduced consumer demand during the initial phase of the pandemic. However, by the end of 2021, many countries were fully vaccinated, and governments announced relaxation in certain regulations, including lockdowns and travel bans. People started traveling to different places, which increased the demand for screen printing mesh. All these factors positively impacted the growth of the screen printing mesh market across different regions.

Screen Printing Mesh Market Regional Insights

Screen Printing Mesh Market Regional Insights

The regional trends and factors influencing the Screen Printing Mesh Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Screen Printing Mesh Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Screen Printing Mesh Market

Screen Printing Mesh Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2022 | US$ 752.70 Million |

| Market Size by 2030 | US$ 1,007.36 Million |

| Global CAGR (2022 - 2030) | 3.7% |

| Historical Data | 2020-2021 |

| Forecast period | 2023-2030 |

| Segments Covered |

By Product Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

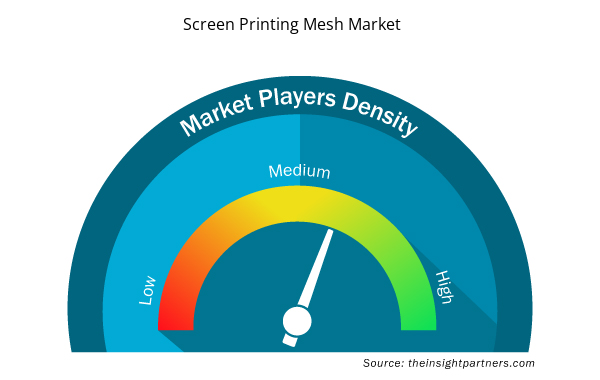

Screen Printing Mesh Market Players Density: Understanding Its Impact on Business Dynamics

The Screen Printing Mesh Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Screen Printing Mesh Market are:

- NBC Meshtec

- Asada Mesh

- Nippon Tokushu Fabric

- HEBEI ANPING PRINTING SCREEN CO., LTD

- QINGDAO GREATWALL INDUSTRY CO., LTD

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Screen Printing Mesh Market top key players overview

Competitive Landscape and Key Companies:

NBC Meshtec; Asada Mesh; Nippon Tokushu Fabric; HEBEI ANPING PRINTING SCREEN CO., LTD; QINGDAO GREATWALL INDUSTRY CO., LTD; Shanghai Gold-Up Screen Printing Facilities Co. Ltd.; Sefar AG; Saati SPA; HAVER & BOECKER OHG; and Weisse & Eschrich GmbH & Co. KG. are among the prominent players operating in the global screen printing mesh market. These players offer high-quality screen printing mesh and cater to many consumers in the global market.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Product Type, Material, and Application

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

This text is related

to country scope.

Frequently Asked Questions

The major players operating in the global screen printing mesh market are NBC Meshtec; Asada Mesh; Nippon Tokushu Fabric; HEBEI ANPING PRINTING SCREEN CO., LTD; QINGDAO GREATWALL INDUSTRY CO., LTD; Shanghai Gold-Up Screen Printing Facilities Co. Ltd.; Sefar AG; Saati SPA; HAVER & BOECKER OHG; and Weisse & Eschrich GmbH & Co. KG.`

Screen printing has emerged as a crucial technology in the production of solar panels, and its demand has been steadily growing in recent years. This trend is primarily driven by its cost-effectiveness and efficiency in manufacturing photovoltaic cells. Screen printing allows for the precise application of conductive materials, such as silver paste, onto solar cell surfaces, enabling the creation of electrical pathways. This method's popularity has surged due to its ability to produce high-quality solar panels at a lower cost, making renewable energy more accessible to a broader audience.

Asia Pacific accounted for the largest share of the global screen printing mesh market. Asia Pacific is one of the most significant regions for the screen printing mesh market owing to drastic increase in the demand for printed apparel.

Based on material, the screen printing mesh market is segmented into polyester, nylon, tungsten, stainless steel, and others. The screen printing mesh market share for the polyester segment was notable in 2022. Polyester screen printing mesh is a vital and widely used material in screen printing, appreciated for its exceptional versatility and durability. Polyester, a synthetic polymer, serves as the foundation for this mesh, and its inherent qualities make it an ideal choice for a wide range of printing applications. One of the standout characteristics of polyester screen printing mesh is its strength and resilience.

The increasing trend of printed clothing is driving the demand for screen printing mesh in the apparel industry. In recent years, there has been a growing trend toward printed clothing, with consumers seeking unique and individualized items that reflect their style. This trend has propelled the demand for screen printing mesh in the apparel industry, as it allows for high-quality and precise printing of custom designs onto a wide range of fabrics and materials. Screen printing mesh is particularly popular for creating t-shirts, hoodies, and other garments with custom graphics or logos.

Based on product type, the screen printing mesh market is segmented into regular and dyed. The regular segment held a larger market share in 2022. Regular screen printing mesh is a fundamental and often underestimated component in printing and textile production. Printing mesh crafted from premium materials such as polyester and nylon serves as the unassuming canvas upon which intricate designs and patterns are expressed. Its significance lies in its ability to act as a blank slate, ensuring that the colors and details of the final print remain true to the original artwork.

Trends and growth analysis reports related to Consumer Goods : READ MORE..

The List of Companies - Screen Printing Mesh Market

- NBC Meshtec

- Asada Mesh

- Nippon Tokushu Fabric

- HEBEI ANPING PRINTING SCREEN CO., LTD

- QINGDAO GREATWALL INDUSTRY CO., LTD

- Shanghai Gold-Up Screen Printing Facilities Co. Ltd.

- Sefar AG

- Saati SPA

- HAVER & BOECKER OHG

- Weisse & Eschrich GmbH & Co. KG

Get Free Sample For

Get Free Sample For