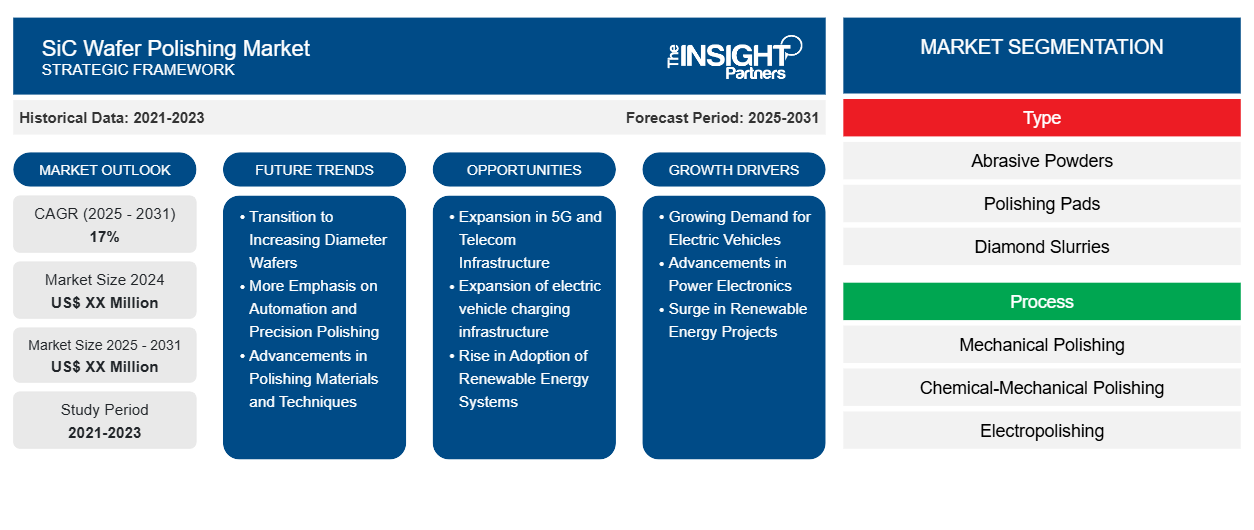

The SiC Wafer Polishing Market is expected to register a CAGR of 17% from 2025 to 2031, with a market size expanding from US$ XX Million in 2024 to US$ XX Million by 2031.

The SiC wafer polishing market report is segmented by Type (Abrasive Powders, Polishing Pads, Diamond Slurries, Colloidal Silica Suspensions, and Others). The market is segmented based on Process (Mechanical Polishing, Chemical-Mechanical Polishing, Electropolishing, Plasma-assisted Polishing, and Others) and Application (Power Electronics, Light-Emitting Diodes (LEDs), Sensors and Detectors, RF and Microwave Devices, and Others). The market size and forecast at global, regional, and country levels for all the key market segments are covered under the scope. The report offers the value in USD for the above analysis, segments, regions, and countries. The report covers market trends, as well as market dynamics such as drivers, restraints, and key opportunities. The report also covers industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments in the market.

Purpose of the Report

The report SiC Wafer Polishing Market by The Insight Partners aims to describe the present landscape and future growth, top driving factors, challenges, and opportunities. This will provide insights to various business stakeholders, such as:

- Technology Providers/Manufacturers: To understand the evolving market dynamics and know the potential growth opportunities, enabling them to make informed strategic decisions.

- Investors: To conduct a comprehensive trend analysis regarding the market growth rate, market financial projections, and opportunities that exist across the value chain.

- Regulatory bodies: To regulate policies and police activities in the market with the aim of minimizing abuse, preserving investor trust and confidence, and upholding the integrity and stability of the market.

SiC Wafer Polishing Market Segmentation

Type

- Abrasive Powders

- Polishing Pads

- Diamond Slurries

- Colloidal Silica Suspensions

Process

- Mechanical Polishing

- Chemical-Mechanical Polishing

- Electropolishing

- Plasma-assisted Polishing

Application

- Power Electronics

- Light-Emitting Diodes

- Sensors and Detectors

- RF and Microwave Devices

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

SiC Wafer Polishing Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

SiC Wafer Polishing Market Growth Drivers

- Growing Demand for Electric Vehicles: Electric vehicles (EVs) are the biggest demand driver for the SiC wafer polishing market. SiC wafers are crucial in power electronic components for EVs, especially in electric motors and power inverters. When the demand for EVs goes up, so does the demand for high-performance SiC wafers that need precise polishing, thereby boosting market growth.

- Advancements in Power Electronics: The continuous advancements in power electronics, especially in energy-efficient devices, are driving the SiC wafer polishing market. SiC wafers are crucial in power devices for applications in renewable energy, industrial equipment, and consumer electronics due to their superior performance at high temperatures. Polishing is a critical step in producing high-quality SiC wafers, making it essential for achieving optimal device performance.

- Surge in Renewable Energy Projects: Another driver for the SiC wafer polishing market is the increasing interest in renewable energy, including solar and wind power. SiC wafers are applied in power conversion systems, which assist in optimizing energy efficiency in renewable energy applications. With the increasing investments by governments and companies in clean energy solutions, the demand for SiC wafers and therefore their polishing will keep increasing and contribute to the growth of the market.

SiC Wafer Polishing Market Future Trends

- Transition to Increasing Diameter Wafers: The SiC wafer polishing market trend is primarily the transition toward more and more higher diameter wafers. As semiconductor producers work to decrease costs and maximize efficiency, larger SiC wafers are produced for the high-power application. Thus, polishing those larger-diameter wafers becomes a challenging and sophisticated technology that requires further development, thereby increasing innovation in the market and growth within the industry to meet such new demands of manufacturing.

- More Emphasis on Automation and Precision Polishing: The trend of more and more automation in the process of wafer polishing is picking up momentum. High-quality, defect-free surfaces that can be achieved in polishing processes are critical for SiC wafers, particularly in power electronics and EV applications. Automation technologies including robotic arms and AI-driven systems are being integrated into polishing processes to increase the speed, accuracy, and consistency of the process while enhancing overall efficiency.

- Advancements in Polishing Materials and Techniques: Continuous developments of polishing materials and techniques determine the SiC wafer polishing market. New slurry, pads, and CMP and other innovative methods are invented to cater to the growing demands for high-quality SiC wafers. Improved surface smoothness, a reduction in defects, and an increase in yield through SiC wafer production contribute to market growth.

SiC Wafer Polishing Market Opportunities

- Expansion in 5G and Telecom Infrastructure: The demand for 5G technology has also opened a significant market opportunity for the SiC wafer polishing market. Silicon carbide wafers are very crucial in the high-frequency, high-power devices used in 5G infrastructure, including the base stations and antennas. As telecom companies continue expanding their networks across the world, the demand for good-quality SiC wafers—and the polishing processes to ensure their performance—is growing continuously.

- Expansion of electric vehicle charging infrastructure: Expansion of electric vehicle charging infrastructure will remain a key driver given rising electric vehicle (EVs) demand. It seems that SiC-based applications become dominant parts within high-power electronics, the cornerstone of fast-charging EV stations, which guarantee exceptional efficiency and thermal robustness. The market's enormous growth prospects in meeting future demands for reliable and powerful components in EV-charging solutions make it challenging in terms of the available requirements for SiC wafers.

- Rise in Adoption of Renewable Energy Systems: Renewable energy systems, including solar power and wind energy, are gaining acceptance globally. These systems involve the use of SiC wafers in power converters that are used for efficient conversion of energy. With a growing investment in renewable energy infrastructure, the demand for polished SiC wafers in energy applications is likely to increase further.

SiC Wafer Polishing Market Regional Insights

The regional trends and factors influencing the SiC Wafer Polishing Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses SiC Wafer Polishing Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for SiC Wafer Polishing Market

SiC Wafer Polishing Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ XX Million |

| Market Size by 2031 | US$ XX Million |

| Global CAGR (2025 - 2031) | 17% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

SiC Wafer Polishing Market Players Density: Understanding Its Impact on Business Dynamics

The SiC Wafer Polishing Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the SiC Wafer Polishing Market are:

- Kemet International

- Entegris

- Iljin Diamond

- Fujimi Corporation

- Saint-Gobain

- JSR Corporation

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the SiC Wafer Polishing Market top key players overview

Key Selling Points

- Comprehensive Coverage: The report comprehensively covers the analysis of products, services, types, and end users of the SiC Wafer Polishing Market, providing a holistic landscape.

- Expert Analysis: The report is compiled based on the in-depth understanding of industry experts and analysts.

- Up-to-date Information: The report assures business relevance due to its coverage of recent information and data trends.

- Customization Options: This report can be customized to cater to specific client requirements and suit the business strategies aptly.

The research report on the SiC Wafer Polishing Market can, therefore, help spearhead the trail of decoding and understanding the industry scenario and growth prospects. Although there can be a few valid concerns, the overall benefits of this report tend to outweigh the disadvantages.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

- Nuclear Waste Management System Market

- Fish Protein Hydrolysate Market

- Airline Ancillary Services Market

- Mobile Phone Insurance Market

- Artwork Management Software Market

- Trade Promotion Management Software Market

- Medical Devices Market

- Photo Editing Software Market

- Environmental Consulting Service Market

- Intradermal Injection Market

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

This text is related

to segments covered.

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

This text is related

to country scope.

Frequently Asked Questions

The SiC wafer polishing market is estimated to witness a CAGR of 17% from 2025 to 2031

Increasing Demand for Electric Vehicles (EVs) is driving the market growth.

Kemet International, Entegris, Iljin Diamond, Fujimi Corporation, Saint-Gobain, JSR Corporation, Engis Corporation, Ferro Corporation, 3M, SKC, DuPont Incorporated, and Fujifilm Holding America Corporation are the key players operating in the SiC wafer polishing market.

Based on process, the chemical mechanical polishing segment is expected to witness the fastest growth during the forecast period.

Based on geography, Asia Pacific held the largest share of the SiC wafer polishing market.

Shift toward larger diameter wafers is expected to be the key market trends.

Trends and growth analysis reports related to Chemicals and Materials : READ MORE..

- Kemet International

- Entegris

- Iljin Diamond

- Fujimi Corporation

- Saint-Gobain

- JSR Corporation

- Engis Corporation

- Ferro Corporation

- 3M

- SKC

- DuPont Incorporated

- Fujifilm Holding America Corporation

Get Free Sample For

Get Free Sample For