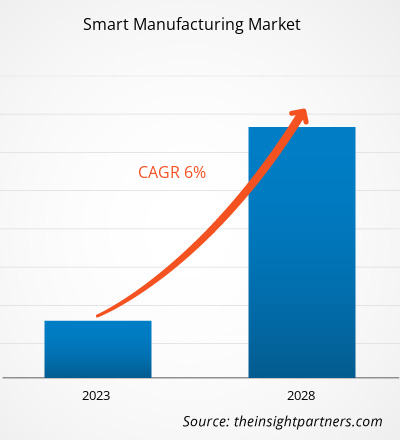

[Research Report] The smart manufacturing market is expected to grow from US$ 249.628 billion in 2022 to US$ 365.22 billion by 2028; it is estimated to grow at a CAGR of 6.0% from 2022 to 2028.

Analyst Perspective:

The smart manufacturing market has witnessed significant growth and innovation in recent years. Smart manufacturing, or Industry 4.0 or the Fourth Industrial Revolution, refers to integrating advanced technologies, such as artificial intelligence (AI), the Internet of Things (IoT), cloud computing, big data analytics, and robotics, into manufacturing. Smart manufacturing solutions have transformed traditional manufacturing operations by enhancing efficiency, productivity, and flexibility. These technologies enable real-time monitoring, automation, predictive maintenance, and intelligent decision-making, improving quality control, reducing downtime, optimizing supply chains, and cost savings. The smart manufacturing market encompasses various sectors, including automotive, aerospace, electronics, pharmaceuticals, food and beverage, and consumer goods. The automotive industry, in particular, has embraced smart manufacturing practices to streamline production, enhance product customization, and meet the growing need for electric vehicles and autonomous driving. In addition to improving operational efficiency, smart manufacturing focuses on sustainability and environmental impact. By optimizing resource utilization, reducing waste, and implementing energy-efficient practices, manufacturers can minimize their carbon footprint and contribute to sustainable development. The global smart manufacturing market is foreseen to grow in the coming years. Factors driving this growth include the increased demand for automation, the need for real-time data analytics and predictive maintenance, and the increasing adoption of IoT devices and cloud platforms. Furthermore, technological advancements like 5G connectivity and edge computing are expected to accelerate the adoption of smart manufacturing solutions.

Market Overview:

The term "smart manufacturing" describes a global industry strategy based on the development of innovative, integrated production technologies and solutions that have been implemented ever-increasingly worldwide. For optimal and scalable control of production operations, it is necessary to introduce systems in manufacturing plants where machines are interconnected using the Internet. Some well-known technologies in smart manufacturing include the Industrial Internet of Things (IIoT), blockchain in manufacturing, robotics, ERP systems, preventive maintenance, augmented reality and virtual reality, data analytics, and automated packaging. For this reason, industrial enterprises continue to invest in and develop new methods of applying these technologies to increase production efficiency. There has also been an expansion of efforts to boost market products. A next generation of smart manufacturing platforms and Smart Factory connectivity is being created by a coalition of US-based industrial organizations, technology suppliers, R&D facilities, and universities known as the Smart Manufacturing Leadership Coalition.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Smart Manufacturing Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Smart Manufacturing Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Market Driver:

Increase in Industrial Robot Adoption to Drive Growth of Smart Manufacturing Market

As more and more industries need to be automated, the deployment of industrial robots has increased. Industrial robots have contributed to the market's growth due to their expanding electronics sector and increasing labor costs in manufacturing. This will likely lead to an increased need for industrial robots during the study period, which could support market growth in smart manufacturing. As a result of the increasing focus on Green Technology and Energy Efficiency, companies can increase their market share and attract new clients by delivering Smart Manufacturing that uses less power and is more energy efficient. The investments in green systems are expected to grow by a staggering amount during the forecast period. Industrial robots are being increasingly used in the manufacturing industry to improve product efficiency, productivity, and quality. They can perform repetitive tasks with high precision, speed, and accuracy, which helps reduce errors and improve product quality. Tasks that are hazardous or difficult for human beings to carry out, e.g., working in an unsafe environment or moving objects of considerable size, are also carried out by robots. New technologies like machine learning, artificial intelligence, and the Internet of Things IoT that enables robots to be smarter and more effective are also being developed in response to the increasing adoption of Industrial Robots. These technologies are helping to create a new generation of smart robots capable of working collaboratively with humans and other robots to accomplish intricate manufacturing tasks. The increasing adoption of industrial robots is also driving the expansion of the smart manufacturing market by increasing the demand for automation solutions, data analytics, and other technologies that are being used to optimize manufacturing processes and improve product quality.

Segmental Analysis:

Based on end user, the smart manufacturing market is segmented into discrete industry and process industry. The discrete segment held the largest share of the market in 2020 and is anticipated to register the highest CAGR in the market during the forecast period. The discrete segment in the smart manufacturing market had the largest share due to the growing demand for automation and digitization in discrete manufacturing processes such as automotive, aerospace, and defense. Adopting smart manufacturing technologies in these industries has helped improve efficiency, reduce costs, and enhance quality control. This has led to increased demand for smart manufacturing solutions, driving growth in the discrete segment of the market. Additionally, the increasing focus on Industry 4.0 and the Industrial Internet of Things (IIoT) is anticipated to further drive growth in the discrete segment of the smart manufacturing market.

Regional Analysis:

The Asia Pacific smart manufacturing market was valued at US$ 78.76 billion in 2022 and is projected to reach US$ 111.53million by 2028; it is expected to grow at a CAGR of 5.5 % during the forecast period. The Asia Pacific region accounted for the largest market share. Over the forecast period, the region is also expected to experience the fastest growth. Developing nations like China and India are pursuing complete automation in smart manufacturing since there are so many untapped prospects in these markets. Due to several factors, the Asia Pacific region has become a dominant player in the smart manufacturing market. One of the primary reasons for the region's dominance is the significant investment made by governments and private organizations in developing advanced manufacturing technologies. Countries like China, Japan, and South Korea invest heavily in developing technologies such as robotics, artificial intelligence, and the Internet of Things (IoT) to improve manufacturing processes and increase productivity. In addition to government and private sector investment, the Asia Pacific region has an extensive and skilled workforce essential for developing and deploying advanced manufacturing technologies. The region has a large pool of highly skilled engineers, scientists, and technicians capable of developing and implementing new technologies in the manufacturing sector. The Asia Pacific region is also an abode to many of the world's leading manufacturing companies, particularly in the electronics and automotive sectors. These companies invest heavily in developing advanced manufacturing technologies to improve efficiency, reduce costs, and increase productivity. As an outcome, the region is becoming a hub for innovation in the manufacturing sector, with many new technologies being developed and tested before being rolled out globally.

The increasing demand for customized products also drives the development of the smart manufacturing market in the Asia Pacific region. As consumers become more demanding and expect products that meet their needs, manufacturers are turning to advanced technologies such as 3D printing and machine learning to create customized products quickly and efficiently. The Asia Pacific region is well-positioned to take advantage of this trend, with many of the world's leading 3D printing companies based in the region. Finally, the Asia Pacific region also benefits from the increasing endorsement of cloud computing and big data analytics in manufacturing. These technologies are being used to collect and analyze vast amounts of data from various sources, including sensors, machines, and other devices, to determinate patterns and trends that can be utilized to improve manufacturing processes and product quality. The region has a large and growing cloud computing infrastructure, which is helping to propel the adoption of these technologies in the manufacturing sector..

Key Player Analysis:

The smart manufacturing market analysis consists of the players such as Yokogawa Electric Corporation; Cisco Systems, Inc; Honeywell International Inc.; 3D Systems, Inc; Daifuku Co., Ltd; GENERAL ELECTRIC; IBM Corporation; Oracle Corporation; Siemens AG; and Schneider Electric SE. Among the players in the smart manufacturing, Cisco Systems, Inc. and Siemens AG are the top two players owing to the diversified product portfolio offered.

Smart Manufacturing Market Regional Insights

Smart Manufacturing Market Regional Insights

The regional trends and factors influencing the Smart Manufacturing Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Smart Manufacturing Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Smart Manufacturing Market

Smart Manufacturing Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2022 | US$ 258.72 Billion |

| Market Size by 2028 | US$ 365.22 Billion |

| Global CAGR (2022 - 2028) | 6.0% |

| Historical Data | 2020-2021 |

| Forecast period | 2023-2028 |

| Segments Covered |

By End User

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

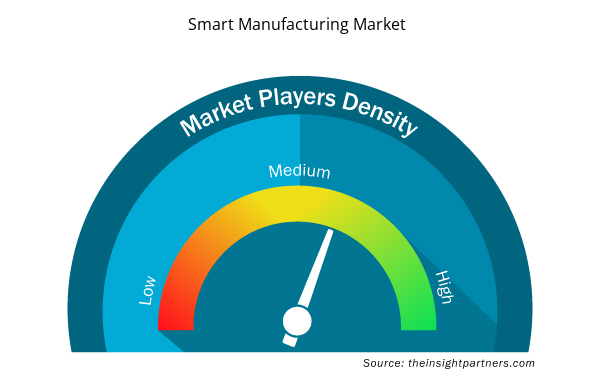

Smart Manufacturing Market Players Density: Understanding Its Impact on Business Dynamics

The Smart Manufacturing Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Smart Manufacturing Market are:

- Yokogawa Electric Corporation

- Cisco Systems, Inc

- Honeywell International Inc.

- 3D Systems, Inc

- Daifuku Co., Ltd

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Smart Manufacturing Market top key players overview

Recent Developments:

Inorganic and organic strategies such as mergers and acquisitions are highly adopted by companies in the smart manufacturing market. A few recent key market developments are listed below:

- In October 2022 - ABB announced that Accelleron Industries AG, a pioneer in high-power turbochargers for mission-critical applications, has been authorized to start trading on the SIX Swiss Exchange in Zurich under the ticker symbol "ACLN." This is done to complete Accelleron's spin-off from ABB.

- In July 2022 - ABB and SKF entered into a Memorandum of Understanding (MoU) to explore the possibilities for collaboration in the automation of manufacturing processes. Through the partnership, the companies will identify and evaluate solutions to improve manufacturing capabilities and support clients’ increased production efficiency.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

End User and Components

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

Argentina, Australia, Brazil, Canada, China, France, Germany, India, Italy, Japan, Mexico, Russian Federation, Saudi Arabia, South Africa, South Korea, United Arab Emirates, United Kingdom, United States

Frequently Asked Questions

APAC is the fastest-growing regional market in the global Smart manufacturing market in 2021.

The global smart manufacturing market was valued at US$ 258.72 Bn in 2022

The Future trends impacting the smart manufacturing market are:

1. 3D robotics

2. AI

3. IoT technologies

The hardware segment led the smart manufacturing in 2021.

US, Germany, India, South Africa, and Brazil are the countries are registering a high growth rate during the forecast period.

The global smart manufacturing market size is projected to reach US$ 365.22 Bn by 2028.

The driving factors impacting the Smart manufacturing market are

1. Surging Adoption of RTLS

2. Increasing Trend of Industry 4.0

The incremental growth of the smart manufacturing market during the forecast period is US$ 22.0 billion with a CAGR of 6.0%

The key players holding the major market share of smart manufacturing are General Electric Company; Honeywell International Inc.; Oracle Corporation; Schneider Electric SE; Siemens AG; Hitachi Ltd; Alstom SA; Irdeto; Raytheon Technologies Corporation; and ENSCO Inc.

Trends and growth analysis reports related to Technology, Media and Telecommunications : READ MORE..

The List of Companies - Smart Manufacturing Market

- Yokogawa Electric Corporation

- Cisco Systems, Inc

- Honeywell International Inc.

- 3D Systems, Inc

- Daifuku Co., Ltd

- GENERAL ELECTRIC

- IBM Corporation

- Oracle Corporation

- Siemens AG

- Schneider Electric SE

Get Free Sample For

Get Free Sample For