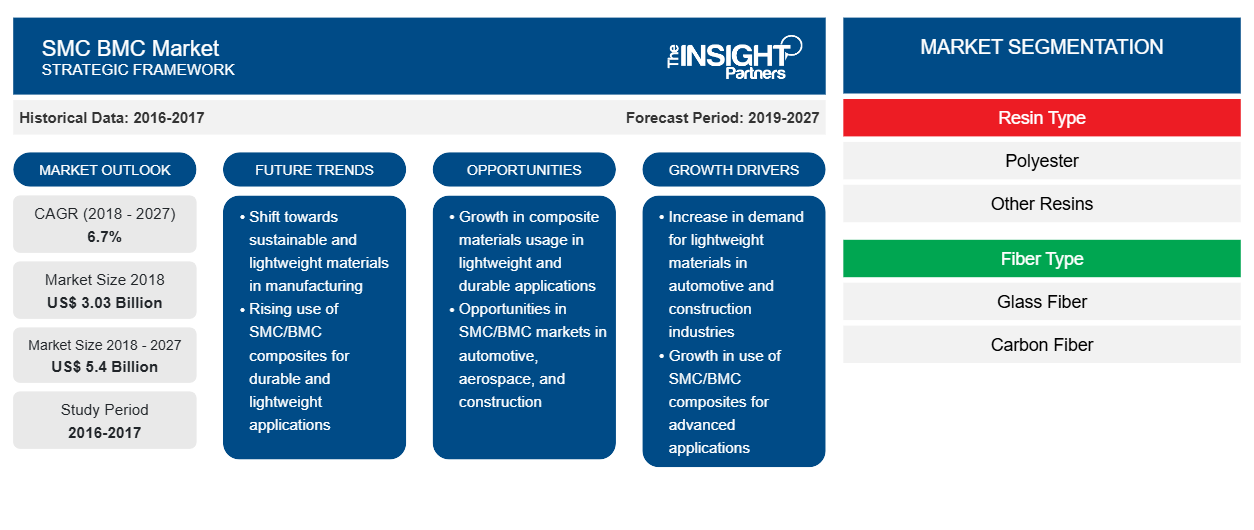

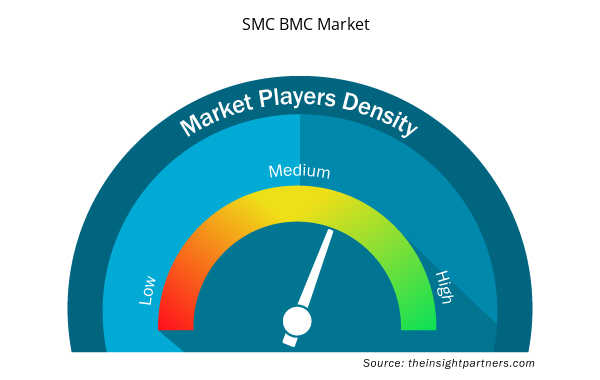

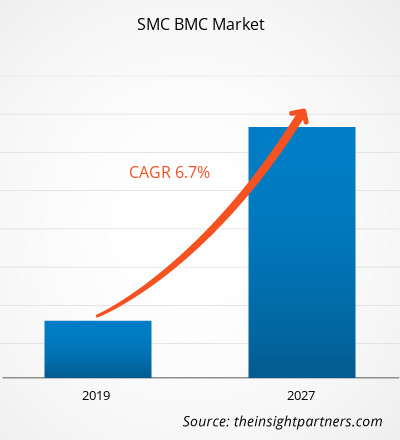

The SMC BMC market was valued at US$ 3,025.97 million in 2018 and is expected to grow at a CAGR of 6.7% from 2019 to 2027 to reach US$5,398.14 million by 2027.

Sheet molding composite (SMC) or sheet molding compound is known as a ready-to-mold glass fiber reinforced with polyester material primarily used in compression molding. The sheet is provided by the manufacturers in rolls weighing up to 1,000 kg. The resin is alternatively coupled with related materials and can be mixed on-site when a manufacturer wants greater control over the chemistry and filler. This is manufactured by dispersing long strands of chopped fiber, basically glass fibers or carbon fibers on a bath of thermoset resins such as polyester resin, vinyl ester resin, and epoxy resin. The longer fibers present in SMC result in better strength properties than sheet and bulk molding compounds (BMC) products. Typical applications of SMC include demanding electrical applications, corrosion-resistant needs, structural components at low cost, automotive, and transit. Bulk molding compound is a ready-to-mold, glass fiber reinforced thermoset polymer material used in compression molding, along with injection molding and transfer molding. Based on resin type, the SMC BMC market is categorized into polyester and other resins. Based on fiber type, the SMC BMC market is bifurcated into glass fiber and carbon fiber. Based on end-use industry, the SMC BMC market is segmented into automotive &transportation, aerospace, electrical &electronics, building &construction, and other end-use industries.

North America is expected to grow at the highest CAGR of 6.9% during the forecast period.Several domestic and international companies have a strong foothold in the North America. In North America, the US is a major market for SMC BMC, followed by Canada and Mexico. The region largely supports the growth of the SMC BMC market through effective manufacture and trade policies.SMC and BMC are fiber-reinforced polymer composite known for higher mechanical strength, high dimensional stability, excellent electrical properties and many other relative properties. These properties make them ideal for use in several end-use industries, such as automotive &transportation, aerospace, and building &construction. Therefore, the growth in these industries in the region is expected to lead to the growth of the SMCBMC market. Major market players present in the North American SMC BMC market are constantly working toward new product developments with improved characteristics and qualities, which is again influencing this market in North America.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

SMC BMC Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

SMC BMC Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Effect of COVID-19 upon SMC BMC market:

Corona-virus outbreak first began in Wuhan (China) during December 2019, and since then it has spread across the globeat a fast pace.China, Italy, Iran, Spain, the Republic of Korea, France, Germany, and the US are among the worst affected countries in terms confirmed cases and reported deaths as of March 2020. According to the latest WHO figures, there are ~332,930 confirmed cases and 14,510 total deaths globally. The coronavirus outbreak has affected economies and industries in various countries due to lockdowns, travel bans, and business shutdowns. The global chemical and materials industry is one of the major industries suffering serious disruptions such as supply chain breaks, technology events cancellations, and office shutdowns as a result of this outbreak.For instance, China is the global hub of manufacturing and the largest raw material supplier for various industries. The overall market break down due to COVID-19 is also affecting the market growth of SMC BMC due to shutting down of factories, obstacle in supply chain, and downturn in world economy.

Market Insights

Rising Demand for Lightweight, High Strength, and Fire & Temperature Resistant Materials

The demand for lightweight materials with high tensile strength is on the rise among several industries such as automotive, aviation, building &construction. The use of lightweight materials has a direct impact upon the overall dynamics and structure of the components in which they are used. SMC and BMC are one such compound material, which are manufactured with the help of thermosetting polymeric matrices. They are known to possess several properties such as good mouldability, high dimensional stability, excellent mechanical and electrical properties, resistance from chemical and corrosion and others. The demand for SMC BMC compounds has considerably increased across automotive and aviation industries owing to rise in advancement and innovation. A slight reduction in the weight can improve the performance of a vehicle. This has offered a great scope in the growth of the SMC and BMC market in the global scenario. Also, BMC composites are gaining traction in several electrical & electronics applications owing to their properties such as resistance toward heat and corrosion, dimensional stability, and others.

Resin Insights

The SMC BMC market, based on resin type, is segmented into polyester and other resins. In 2018, the polyester segment accounted for the largest share of the global SMC BMC market, whereas the other segment is expected to grow at a higher CAGR during the forecast period. SMC and BMC composites are made up of polyester resin coupled with various fibers. Such fibers were initially manufactured for mass consumption by companies such as DuPont Corporation. Fibers manufactured from polyesters are made up of stable and strong ion molecules, filament, tow, and fiberfill,which are the four basic forms of polyester. These composites are used in various end-use industries. The processing of polyester is easy, cost-effective, and needs no post-curing. Initially, polyesters were largely adopted by consumers owing to its durability profile over other natural fibers. Currently, polyester manufacturers are working upon new and improved formulations with better mechanical properties.

Fiber Type Insights

The SMC BMC market, based on fiber type, is segmented into glass fiber and carbon fiber. In 2018, the glass fiber segment accounted for the largest share of the global SMC BMC market, whereas the carbon fiber segment is expected to register the fastest growth rate during the forecast period. Glass fibers are looked upon as versatile class of materials that are extensively used as a reinforcement fiber for polymeric resins including epoxy and unsaturated polyester. Although the glass fibers possess less stiffness over other reinforcement fibers, these exhibit other distinct advantages such as high strength with low density and cost-effectiveness. Such types of fiber contain high tensile strength and good stiffness along with chemical resistance. Glass fibers are quite cheaper, less brittle and are easily available in the market than carbon fibers. Further, its bulk strength and weight properties are considered ideal, and it can be easily manufactured using molding processes. Such properties make it a best suitable material to be used across various applications including manufacturing of SMC BMC composites.

End-Use IndustryInsights

The SMC BMC market, based on end-use industry, is segmented into automotive &transportation, aerospace, electrical & electronics, building &construction, and other end-use industries. The automotive &transportation segment accounted for the largest share of the SMC BMC market in the year of 2018, whereas the building and constructionsegment is expected to register the fastest growth rate during the forecast period. SMC composites offer a comprehensive line of pneumatic products that meet and exceed the demand from the automotive industry. This helps carrying out operation 24/7 in extreme temperatures and weld environments to yield efficient production. SMC has been known to be a versatile reinforced plastic in the field of painted and unpainted automotive componentry, including bumpers, fenders, exterior, and interior panels, structural elements, and high-temperature under hood parts. Recently, SMC formulation and processing innovations have boosted the volume of SMC in automotive parts in North America.Bulk molding compoundsare meant for automotive and transportation body panels that require painting. These composite materials possess a minimal expansion characteristic.SMC and BMC are also used in the manufacturing of different railway parts. These composites offer fire resistance, corrosion resistance, and durability.

Mergers and acquisition and research and development are commonly adopted strategies by companies to expand their footprint worldwide. Core Molding Technologies, IDI Composites International, Toray TCAC Holding B.V., Polynt-Reichhold Group, Continental Structural Plastics Inc.,and Showa Denko K.K. are among the market players implementing mergers and acquisition and research and developmentgrowth strategies to enlarge the customer base and gain significant market share across the world, which, in turn, permit the players to maintain their brand name globally.

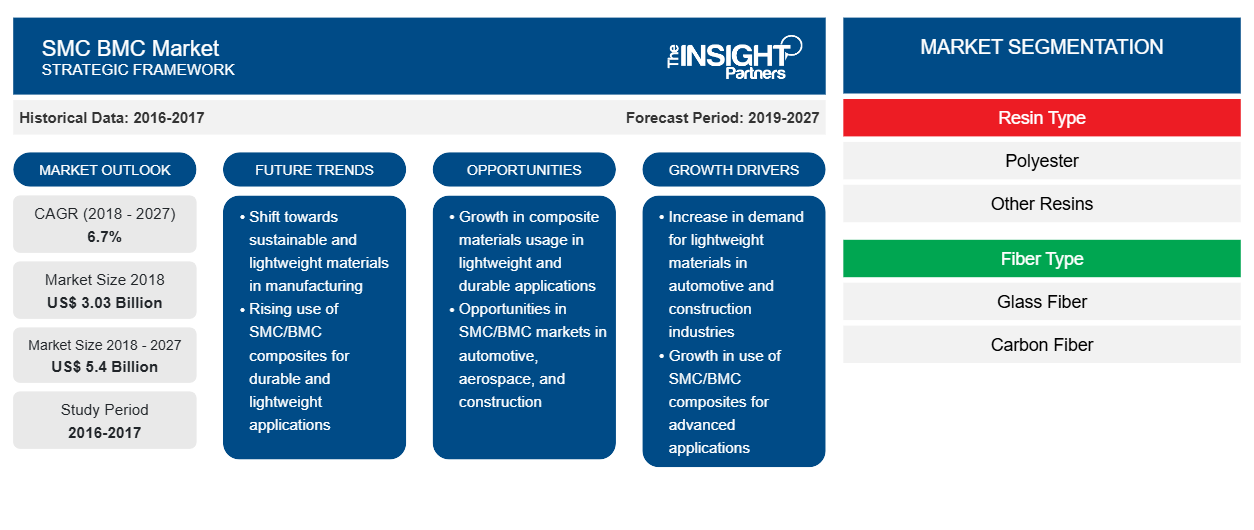

SMC BMC Market Regional Insights

The regional trends and factors influencing the SMC BMC Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses SMC BMC Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for SMC BMC Market

SMC BMC Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2018 | US$ 3.03 Billion |

| Market Size by 2027 | US$ 5.4 Billion |

| Global CAGR (2018 - 2027) | 6.7% |

| Historical Data | 2016-2017 |

| Forecast period | 2019-2027 |

| Segments Covered |

By Resin Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

SMC BMC Market Players Density: Understanding Its Impact on Business Dynamics

The SMC BMC Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the SMC BMC Market are:

- ASTAR S.A.

- Continental Structural Plastics Inc.

- Core Molding Technologies

- HGGC, LLC.

- IDI Composites International

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the SMC BMC Market top key players overview

Global SMC BMC Market – By Resin Type

- Polyester

- Other Resins

Global SMC BMC Market – By Fiber Type

- Glass Fiber

- Carbon Fiber

Global SMC BMC Market – By End-Use Industry

- Automotive &Transportation

- Aerospace

- Electrical &Electronics

- Building &Construction

- Other End-Use Industries

Company Profiles

- ASTAR S.A.

- Core Molding Technologies

- IDI Composites International

- Toray TCAC Holding B.V.

- MENZOLIT

- Polynt SpA

- Showa Denko K.K.

- HGGC, LLC.

- Continental Structural Plastics Inc.

- LORENZ

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Resin Type ; Fiber Type ; End-Use Industry � ��

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

Argentina, Australia, Brazil, Canada, China, France, Germany, India, Japan, Mexico, Russian Federation, Saudi Arabia, South Africa, United Arab Emirates, United Kingdom, United States

Frequently Asked Questions

In 2018, the SMC BMC market was predominant in Asia Pacific at the global level. The manufacturing sector in Asia Pacific rapidly adopts advanced technologies and processes. India, Japan, and China are among the major markets for SMC and BMC in this region. The growing number of SMC BMC uses in automotive, electronic appliances, and building & construction applications are the key factors boosting the growth of the SMC BMC market in Asia Pacific.

The major players operating in the global SMC BMC market are ASTAR S.A.; Core Molding Technologies; IDI Composites International; Toray TCAC Holding B.V.; MENZOLIT; Polynt SpA; Showa Denko K.K.; HGGC, LLC.; Continental Structural Plastics Inc.; and LORENZ; among many others.

The growth of the automotive and transportation segment is primarily attributed to the rising demand for lightweight, strong, and fuel-efficient vehicles. SMC BMC materials find their applications in several parts of passenger and commercial vehicles. It is widely used in body panels of vehicles, lighting systems, headlamp reflectors and LED structural lighting parts, front ends, interior dashboard parts body panels for trucks, and agricultural vehicles.

Trends and growth analysis reports related to Chemicals and Materials : READ MORE..

The List of Companies - SMC BMC Market

- ASTAR S.A.

- Continental Structural Plastics Inc.

- Core Molding Technologies

- HGGC, LLC.

- IDI Composites International

- LORENZ

- MENZOLIT Compounding Solutions

- Polynt SpA

- SHOWA DENKO K.K.

- Toray TCAC Holding B.V

Get Free Sample For

Get Free Sample For