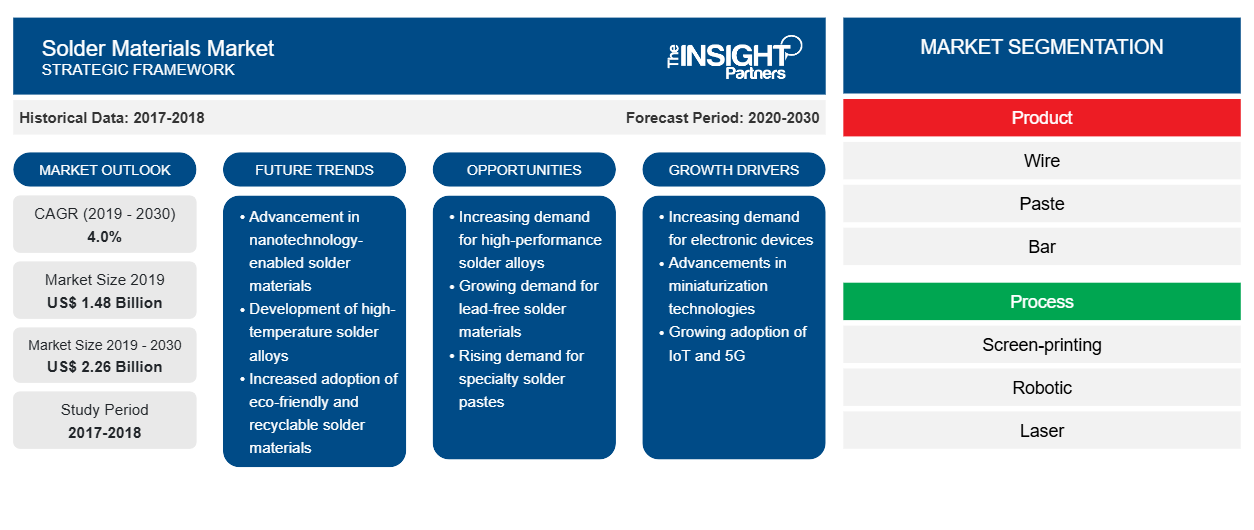

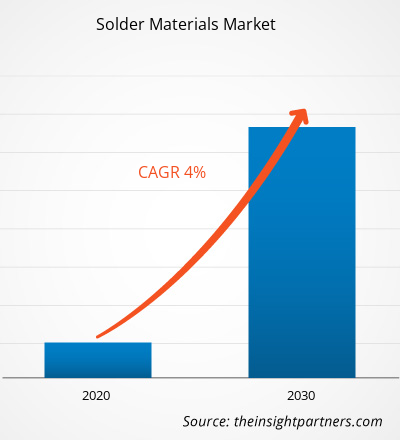

The solder materials market was valued at US$ 1,477.2 million in 2019 and is expected to grow at a CAGR of 4.0% from 2020 to 2030 to reach US$ 2,255.3 million by 2030.

Soldering is known as a process in which two or more than two metals are joined together by melting and followed by placing a filler metal, called solder, into the joint. The filler metal used in the process has a lower melting point compared to the adjoining metal. In the past decades, nearly all solders contained lead; however, environmental and health concerns among consumers have increasingly dictated the use of lead-free alloys for electronics and plumbing purposes. Solder is used in electronics, plumbing, construction, and metalwork in flashing to jewelry, medical, and musical instruments. Solder mainly provides reasonably permanent but reversible connections between copper pipes in plumbing systems along with joints in sheet metal objects such as food cans, rain gutters, roof flashing, and automobile radiators. Electronic solder connects electrical wiring to devices and electronic components to printed circuit boards.

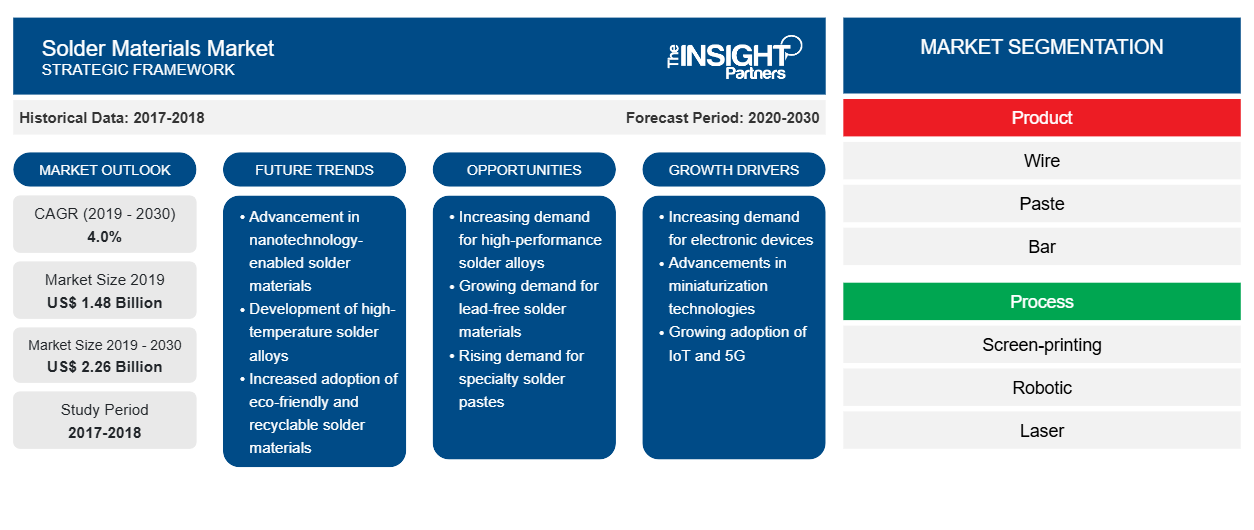

The global solder materials market in Asia Pacific is expected to grow at the highest CAGR of 4.2% from 2020 to 2030.High demand for solder materials along with the consumer shift toward smart electronic products in this region is creating a strong base for solder materials market. With such a considerable growth, Asia Pacific is going to be the most attractive region for solder materials market during the forecast period.

The COVID-19 outbreak, which began in Wuhan (China) in December 2019, has spread around the globe at a fast pace. As of June 2020, the US, Russia, India, China, Italy, Spain, France, and Germany, are among the worst-affected countries in terms of positive cases and reported deaths. According to the WHO figures updated in June 2020, approximately 7,482,952 confirmed cases and 419,497 deaths have been reported globally. The outbreak has affected economies and industries due to lockdowns, travel bans, and business shutdowns. Chemicals and materials is one the world’s major industries suffering serious disruptions such as supply chain breaks, technology events cancellations, and office shutdowns as a result of this pandemic. China is the global manufacturing hub and is the largest raw material supplier for various industries; however, it is also one of the worst-affected countries by the COVID-19 pandemic. The lockdown of various plants and factories in China is affecting the global supply chains and adversely impacting the manufacturing and sales of various chemical and materials. The overall market break down due to COVID-19 is also affecting the solder materials market growth due to shutting down of factories, obstacle in supply chain, and downturn in world economy.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Solder Materials Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Solder Materials Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Market Insights

Increasing Demand from Electronic Industry Favors Solder Materials Market Growth Globally

Rising demand for various smart electronics and the advent of energy-efficient electronics are the major factors to drive the growth of solder materials market. Additionally, the rising production of electronic devices or gadgets in developing countries coupled with the presence of a notable electronics aftermarket industry is expected to boost the demand for solder materials. Conventional micrometer solder materials in the paste exhibit several shortcomings, such as high melting temperatures, which can result in undesired stress during the reflow processing, restricted applications, and defects in the joint. This has further led to the introduction of innovative sub-micron and nanoparticle-based solder materials. Hence, these advancements in the electronic refurbishing sector are likely to propel the growth of the global solder materials market. There are various types of solder materials used in the electronic industry, such as lead-free solder, solder wire, solder ball, and solder bar. Lead-free solders are increasingly used in almost all applications owing to regulatory requirements along with the health & environmental benefits towards avoiding lead-based electronic components. They are mostly used in consumer electronics. For electrical & electronics work, solder wire is available with a range of thicknesses for hand-solder and with cores containing flux.

Product Insights

Based on product, the solder materials market is segmented into wire, paste, bar, flux, and others. The wire segment accounted for the largest share of the global market in 2019; whereas, the market for paste is expected to grow at the highest CAGR during the forecast period. Solder wire comprises different types of alloys, or pure tin. As the combinations of metals that comprise solder wire melts at different temperatures, each metal requires a certain type of solder wire to create strong bonds. The most common metals utilized in solder wire are Lead (Pb) and Tin (Sn). Soft solder basically melts in the range of 190−900°F. Lead-free solders are increasingly used to regulatory requirements along with the health & environmental benefits toward avoiding lead-based electronic components. They are mostly used in consumer electronics.

Process Insights

Based on process, the solder materials market is segmented into screen-printing, robotic, laser, and wave/reflow. The wave/reflow segment accounted for the largest share of the global solder materials market in 2019; whereas, the robotic segment is expected to register the highest CAGR during the forecast period. Wave soldering is a large-scale solder process through which electronic components are soldered mainly to a printed circuit board (PCB) to form an electronic assembly. The name is basically derived since waves of molten solder are used to attach metal components to the PCB. The process utilizes a tank to hold a quantity of molten solder, and the components are inserted into the PCB, and then the loaded PCB is passed through a pumped wave or waterfall of solder. Reflow soldering is one of the processes in which a solder paste is used to temporarily attach one or many tiny electrical components into their contact pads; later, the entire assembly is subjected to controlled heat. The solder paste reflows, in a molten state can create permanent solder joints. Heating is accomplished in this process by passing the assembly through a reflow oven or an infrared lamp or by solder individual joints with a de-solder hot air pencil.

Solder Materials Market Regional Insights

The regional trends and factors influencing the Solder Materials Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Solder Materials Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Solder Materials Market

Solder Materials Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2019 | US$ 1.48 Billion |

| Market Size by 2030 | US$ 2.26 Billion |

| Global CAGR (2019 - 2030) | 4.0% |

| Historical Data | 2017-2018 |

| Forecast period | 2020-2030 |

| Segments Covered |

By Product

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

Solder Materials Market Players Density: Understanding Its Impact on Business Dynamics

The Solder Materials Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Solder Materials Market are:

- Fusion Incorporated

- Indium Corporation

- Kester

- KOKI Company Ltd

- Lucas-Milhaupt, Inc.

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Solder Materials Market top key players overview

Report Spotlights

- Progressive industry trends in the global solder materials market that help players develop effective long-term strategies

- Business growth strategies adopted by developed and developing markets

- Quantitative analysis of the global solder materials market from 2017 to 2030

- Estimation of global solder materials demand across various end use industries

- PEST analysis to illustrate the efficacy of buyers and suppliers operating in the industry to predict market growth

- Recent developments to understand the competitive market scenario and global solder materials demand

- Market trends and outlook, and factors driving and restraining the growth of the global solder materials market

- Understanding of strategies that underpin commercial interest with regard to global solder materials market growth, which facilitates effective decision-making process

- Global solder materials market size at various nodes of market

- Detailed overview and segmentation of the global solder materials market, as well as its dynamics in the industry

- Global solder materials market size in various regions with promising growth opportunities in the respective markets

Solder Materials Market, by Product

- Wire

- Paste

- Bar

- Flux

- Others

Solder Materials Market, by Process

- Wave/Reflow

- Robotic

- Screen Printing

- Laser

Company Profiles

- Fusion Incorporated

- Indium Corporation

- Kester

- KOKI Company Ltd

- Lucas-Milhaupt, Inc.

- Qualitek International, Inc.

- Senju Metal Industry Co., Ltd.

- Stannol GmbH & Co. KG

- TAMURA Corporation

- Nihon Genma

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Product , Process

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

Argentina, Australia, Brazil, Canada, China, France, Germany, India, Italy, Japan, Mexico, Russian Federation, Saudi Arabia, South Africa, South Korea, United Arab Emirates, United Kingdom, United States

Frequently Asked Questions

Major market share of wiresegment is primarily attributed to the fact that for electrical & electronics work, solder wire is available in the market with a range of thicknesses for hand-solder and with cores containing flux. It is further available as a room temperature paste. Jewelers often utilize solder in thin sheets, which they cut into snippets. A soldered joint is basically used to attach a wire to the pin of a component on the rear of a printed circuit board. Solder wire is comprised of different types of alloys, or of pure tin. Each metal requires a certain type of solder wire to create strong bonds, since the combinations of metals that comprise solder wire melt at different temperatures. Lead-free solders are increasing in use owing to regulatory requirements along with the health & environmental benefits towards avoiding lead-based electronic components. They are mostly used in consumer electronics. Steel wire, screwdrivers, nails, and Alan wrenches are all potential tools for emergency solder.

The major players operating in the globalsolder materialsmarketareFusion Incorporated, Indium Corporation, Kester, KOKI Company Ltd, Lucas-Milhaupt, Inc., Qualitek International, Inc., Senju Metal Industry Co., Ltd, Stannol GmbH & Co. KG, Tamura Corporation, and Nihon Genmaamong many others.

In 2019,the solder materialsmarket was predominantin Asia-Pacificat theglobal level.The APAC encompasses huge opportunities for the growth of soldermaterials. The region has surfaced as one of the prominent markets for the utilization of soldermaterials. Asia has ranked highest amongst electronics producing regions. Japan is dominating the regional market, followed by other countries such as China, India, Vietnam, Korea, Thailand, Malaysia, and Indonesia. These countries are witnessing growing demand from the electronic and automobiles industries. Apart from its applications in the electronic industry, the solder materials market has been propelling due to its applications in electronic vehicles. The price for petrol, diesel, and CNG, has increased subsequently that has created opportunities for the electric, coupled with a shift in consumer living standards. This shift has fueled the growth of the market in the region. Moreover, expanding disposable income and increasing purchasing capabilities are predicted to impact market growth positively.

Trends and growth analysis reports related to Chemicals and Materials : READ MORE..

The List of Companies - Global Solder Materials Market

- Fusion Incorporated

- Indium Corporation

- Kester

- KOKI Company Ltd

- Lucas-Milhaupt, Inc.

- Qualitek International, Inc.

- Senju Metal Industry Co., Ltd.

- Stannol GmbH & Co. KG

- TAMURA Corporation

- Nihon Genma

Get Free Sample For

Get Free Sample For