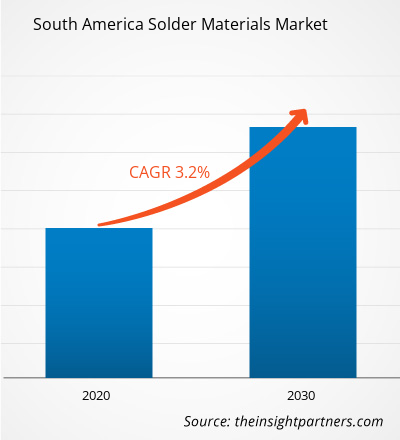

The SAM solder materials market is expected to grow from US$ 104.70 million in 2019 to US$ 146.59 million by 2030; it is estimated to grow at a CAGR of 3.2% from 2020 to 2030.

Brazil and Argentina are major economies in SAM. Rising demand for various smart electronics and the advent of energy-efficient electronics are considered as the major factors expected to drive the North America solder materials market. In addition to that, the rising production of electronic devices or gadgets in developing countries coupled with the presence of a notable electronics aftermarket industry is expected to boost the demand for such materials during the forecast period. Conventional micrometer solder materials in the paste exhibit several shortcomings, such as high melting temperatures, which may result in undesired stress during the reflow processing, restricted applications, and defects in the joint. This has further led to the introduction of the innovation of various sub-micron and nanoparticle-based solder materials. Hence, the solder materials market is likely to be propelled by the development in the sector of electronic refurbishing. There are different types of solder materials such as lead-free solder, solder wire, solder ball, solder bar, and others used in the electronic industry. Lead-free solders are increasing in use owing to regulatory requirements along with the health & environmental benefits towards avoiding lead-based electronic components. They are mostly used in consumer electronics. For electrical & electronics work, solder wire is available in the market with a range of thicknesses for hand-solder and with cores containing flux. Plumbers mostly use bars of solder, much thicker than the wire used for electrical applications and then apply flux separately; note that many plumbing-suitable solder fluxes are too corrosive (or conductive) to be used in electrical or electronic work. For the electronic industry, through different processes such as screen-printing, laser printing, wave and reflow, solder can be achieved. Screen or stencil printing is a process of depositing solder paste on the printed wiring boards (PWBs) to establish electrical connections. Laser solder is basically a technique where a precisely focused laser beam offers controlled heating of the solder alloy, which leads to a fast and non-destructive of an electrical joint. Wave solder is known as a large-scale solder process through which electronic components are soldered mainly to a printed circuit board (PCB) to form an electronic assembly. Reflow solder is one of the processes in which a solder paste is used to temporarily attach one or more than thousands of tiny electrical components into their contact pads; after that, the entire assembly is subjected to controlled heat.As the COVID 19 pandemic continues to grow, it has hampered the solder materials market in SAM. The major countries in the SAM region are under lockdown. In many countries of SAM, where the newest strain of the coronavirus (COVID-19) has made an impact, isolation and social distancing measures have been put in place. The lesser production of goods and commodities is hampering the growth solder materials market as the demand for these solution has weekend over the past couple of months.

With the new features and technologies, vendors can attract new customers and expand their footprints in emerging markets. This factor is likely to drive the SAM solder materials market. The SAM solder materials market is expected to grow at a good CAGR during the forecast period.

SAM Solder Materials Market Revenue and Forecast to 2030 (US$ Mn)

- This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

SAM solder materials market Segmentation

SAM solder materials market, by Product

- Wire

- Paste

- Bar

- Flux

- Others

SAM solder materials market, by Process

- Screen-Printing

- Robotic

- Laser

- Wave/Reflow

SAM solder materials market – By Country

- Argentina

- Brazil

- Rest of SAM

South America Solder Materials Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2019 | US$ 104.70 Million |

| Market Size by 2030 | US$ 146.59 Million |

| Global CAGR (2020 - 2030) | 3.2% |

| Historical Data | 2017-2018 |

| Forecast period | 2020-2030 |

| Segments Covered |

By Product

|

| Regions and Countries Covered | South and Central America

|

| Market leaders and key company profiles |

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Product, and Process (Screen-printing, Robotic, Laser, Wave/Reflow

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

US, Canada, Brazil, Argentina

Trends and growth analysis reports related to Chemicals and Materials : READ MORE..

The List of Companies - South America Solder Materials Market

- Fusion Incorporated

- Indium Corporation

- Kester

- KOKI Company Ltd

- Tamura Corporation

Get Free Sample For

Get Free Sample For