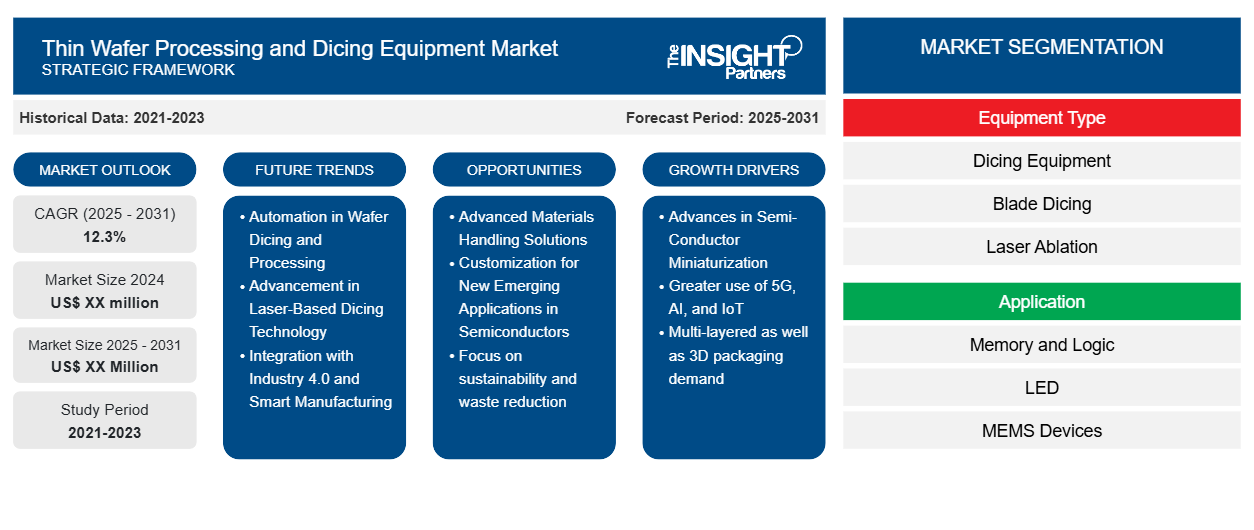

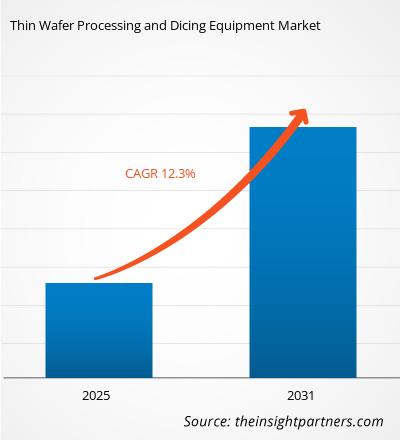

The Thin Wafer Processing and Dicing Equipment Market is expected to register a CAGR of 12.3% from 2025 to 2031, with a market size expanding from US$ XX million in 2024 to US$ XX Million by 2031.

The Thin Wafer Processing and Dicing Equipment Market is categorized by equipment type into the following subsegments: Dicing Equipment, Blade Dicing, Laser Ablation, Stealth Dicing, and Plasma Dicing. It further presents an analysis based on applications, i.e., Memory and Logic, LED, MEMS Devices, Power Devices, CMOS Image Sensors, RFID, and Others. The global analysis is broken down at the regional level and major countries. The market evaluation is presented in US$ for the above segmental analysis.

Purpose of the Report

The report Thin Wafer Processing and Dicing Equipment Market by The Insight Partners aims to describe the present landscape and future growth, top driving factors, challenges, and opportunities. This will provide insights to various business stakeholders, such as:

- Technology Providers/Manufacturers: To understand the evolving market dynamics and know the potential growth opportunities, enabling them to make informed strategic decisions.

- Investors: To conduct a comprehensive trend analysis regarding the market growth rate, market financial projections, and opportunities that exist across the value chain.

- Regulatory bodies: To regulate policies and police activities in the market with the aim of minimizing abuse, preserving investor trust and confidence, and upholding the integrity and stability of the market.

Thin Wafer Processing and Dicing Equipment Market Segmentation

Equipment Type

- Dicing Equipment

- Blade Dicing

- Laser Ablation

- Stealth Dicing

- Plasma Dicing

Application

- Memory and Logic

- LED

- MEMS Devices

- Power Devices

- CMOS Image Sensors

- RFID

- Others

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Thin Wafer Processing and Dicing Equipment Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Thin Wafer Processing and Dicing Equipment Market Growth Drivers

- Advances in Semi-Conductor Miniaturization: The driving nature of miniaturization within the semiconductor industry, particularly the effort toward having even smaller and yet more powerful chips, implies the demand for thin wafer processing and dicing equipment. In such equipment, ultra-thin wafers are cut with high accuracy.

- Greater use of 5G, AI, and IoT: The increasing adoption of cutting-edge technologies such as 5G, AI, and IoT devices is generating an insatiable demand for miniaturized, ultra-thin, high-performance semiconductor devices. Thin wafer processing and dicing equipment play a critical role in the production of smaller high-end chips for these applications.

- Multi-layered as well as 3D packaging demand: The market has become focused towards the semiconductor device using more and more multi-layered as well as 3D packaging technologies. The thin wafer processing and dicing equipment hold a prime position in providing precision to such advanced packaging solutions.

Thin Wafer Processing and Dicing Equipment Market Future Trends

- Automation in Wafer Dicing and Processing: It is a significant trend being seen in wafer processing and dicing. The automated systems ensure faster processing, make fewer defects, and enhanced throughput, thereby helping to improve the demand for semiconductors in every application of smartphones and automotive electronics.

- Advancement in Laser-Based Dicing Technology: There is an increase in laser-based dicing technologies that give non-mechanical cutting solutions for ultra-thin wafers with precision and workability with complex materials without stress or damages caused.

- Integration with Industry 4.0 and Smart Manufacturing: Integration of wafer processing equipment with Industry 4.0 technologies such as IoT, AI, and data analytics enables smart and efficient manufacturing processes in real-time with predictive maintenance and process optimization.

Thin Wafer Processing and Dicing Equipment Market Opportunities

- Advanced Materials Handling Solutions: With smaller and thinner to almost delicates a new opportunity was developed to create advanced material handling solutions for safe processing and transportation of wafers in the manufacturing process.

- Customization for New Emerging Applications in Semiconductors: Thin wafer processing and dicing equipment manufacturers can design solutions for the new application fields of quantum computing, flexible electronics, and even wearable devices that demand special wafer handling capabilities.

- Focus on sustainability and waste reduction: This is an opportunity to develop wafer processing and dicing equipment minimizing material loss and energy consumption that will support more sustainable practices in manufacturing. Focusing on Sustainability and Waste Reduction: the pressure increase upon the semiconductor industry to reduce waste and develop higher energy efficiency would not pass without its opportunities.

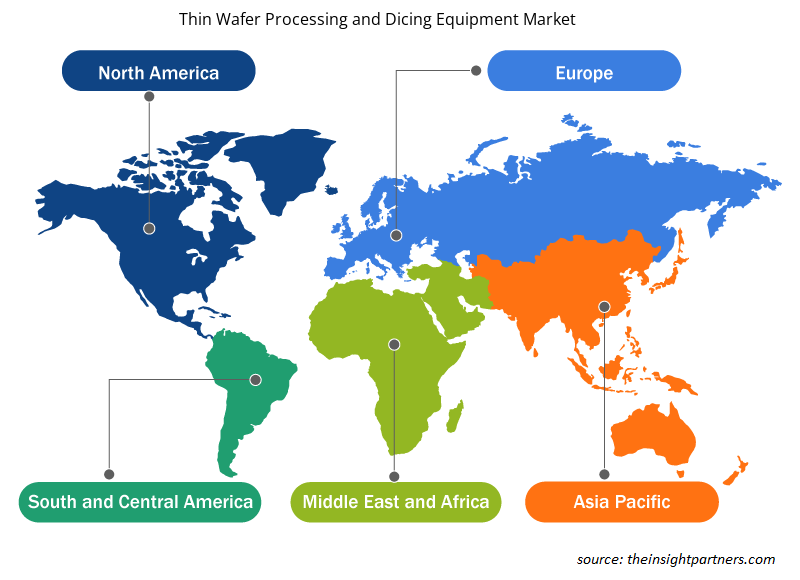

Thin Wafer Processing and Dicing Equipment Market Regional Insights

The regional trends and factors influencing the Thin Wafer Processing and Dicing Equipment Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Thin Wafer Processing and Dicing Equipment Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Thin Wafer Processing and Dicing Equipment Market

Thin Wafer Processing and Dicing Equipment Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ XX million |

| Market Size by 2031 | US$ XX Million |

| Global CAGR (2025 - 2031) | 12.3% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Equipment Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

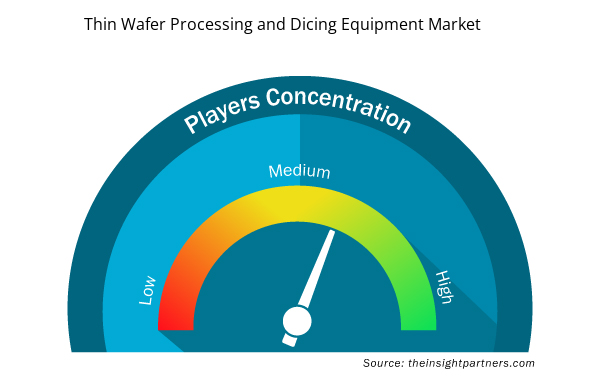

Thin Wafer Processing and Dicing Equipment Market Players Density: Understanding Its Impact on Business Dynamics

The Thin Wafer Processing and Dicing Equipment Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Thin Wafer Processing and Dicing Equipment Market are:

- Suzhou Delphi Laser Co. Ltd

- SPTS Technologies Limited

- Plasma-Therm LLC

- Han's Laser Technology Industry Group Co. Ltd.

- ASM Laser Separation International (ALSI) B.V.

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Thin Wafer Processing and Dicing Equipment Market top key players overview

Key Selling Points

- Comprehensive Coverage: The report comprehensively covers the analysis of products, services, types, and end users of the Thin Wafer Processing and Dicing Equipment Market, providing a holistic landscape.

- Expert Analysis: The report is compiled based on the in-depth understanding of industry experts and analysts.

- Up-to-date Information: The report assures business relevance due to its coverage of recent information and data trends.

- Customization Options: This report can be customized to cater to specific client requirements and suit the business strategies aptly.

The research report on the Thin Wafer Processing and Dicing Equipment Market can, therefore, help spearhead the trail of decoding and understanding the industry scenario and growth prospects. Although there can be a few valid concerns, the overall benefits of this report tend to outweigh the disadvantages.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

- Rare Neurological Disease Treatment Market

- Digital Language Learning Market

- Skin Tightening Market

- Neurovascular Devices Market

- Medical Audiometer Devices Market

- Bathroom Vanities Market

- Wind Turbine Composites Market

- Ketogenic Diet Market

- Photo Editing Software Market

- Intraoperative Neuromonitoring Market

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

This text is related

to segments covered.

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

This text is related

to country scope.

Frequently Asked Questions

Some of the customization options available based on request are additional 3-5 company profiles and country-specific analysis of 3-5 countries of your choice. Customizations are to be requested/discussed before making final order confirmation, as our team would review the same and check the feasibility.

The report can be delivered in PDF/PPT format; we can also share excel dataset based on the request.

Market leadership players include: Suzhou Delphi Laser Co. Ltd, SPTS Technologies Limited, Plasma-Therm LLC, Han's Laser Technology Industry Group Co. Ltd., ASM Laser Separation International (ALSI) B.V., Disco Corporation, Tokyo Seimitsu Co, Ltd. (Accretech), Neon Tech Co. Ltd., Nippon Pulse Motor Taiwan (NPMT), Panasonic Corporation,

The market is expected to register a CAGR of 12.3% during 2023-2031.

Some of the key drivers include demand for high-performance electronics, growth in the semiconductor industry, and an increasing trend in miniaturization of electronic devices are drivers in this market.

Key trends in the market include the increased use of automation and precision technologies and the trend toward 5G and AI applications.

Trends and growth analysis reports related to Electronics and Semiconductor : READ MORE..

1.Suzhou Delphi Laser Co. Ltd

2.SPTS Technologies Limited

3.Plasma-Therm LLC

4.Han's Laser Technology Industry Group Co. Ltd.

5.ASM Laser Separation International (ALSI) B.V.

6.Disco Corporation

7.Tokyo Seimitsu Co, Ltd. (Accretech)

8.Neon Tech Co. Ltd.

9.Nippon Pulse Motor Taiwan (NPMT)

10.Panasonic Corporation

Get Free Sample For

Get Free Sample For