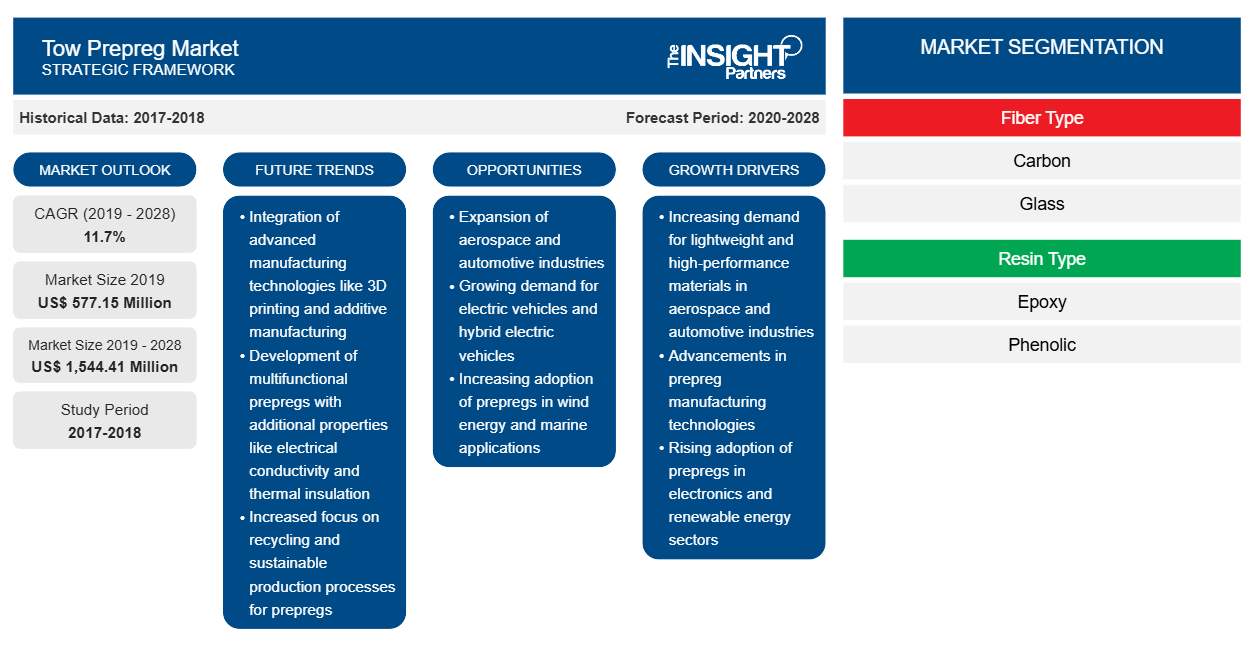

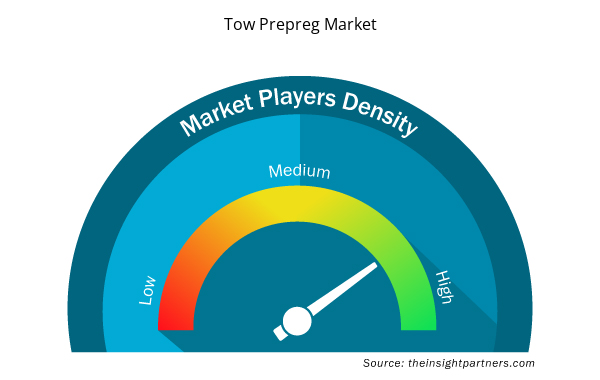

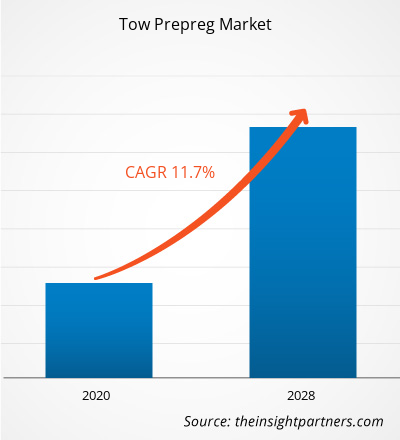

The tow prepreg market was valued at US$ 577.15 million in 2019 and is projected to reach US$ 1,544.41 million by 2028; it is expected to grow at a CAGR of 11.7% from 2020 to 2028.

Tow prepregs are composed of glass fiber filament, carbon, and duro plastic resin which acts as a binding material. The expanding applications of tow prepregs across diversified industrial bases along with growing demand for lightweight and cost-efficient materials drive the growth of the tow prepreg market. Rapid urbanization coupled with economic growth and significant investment in research and development activities are also expected to promote the demand for tow prepregs during the forecast period.

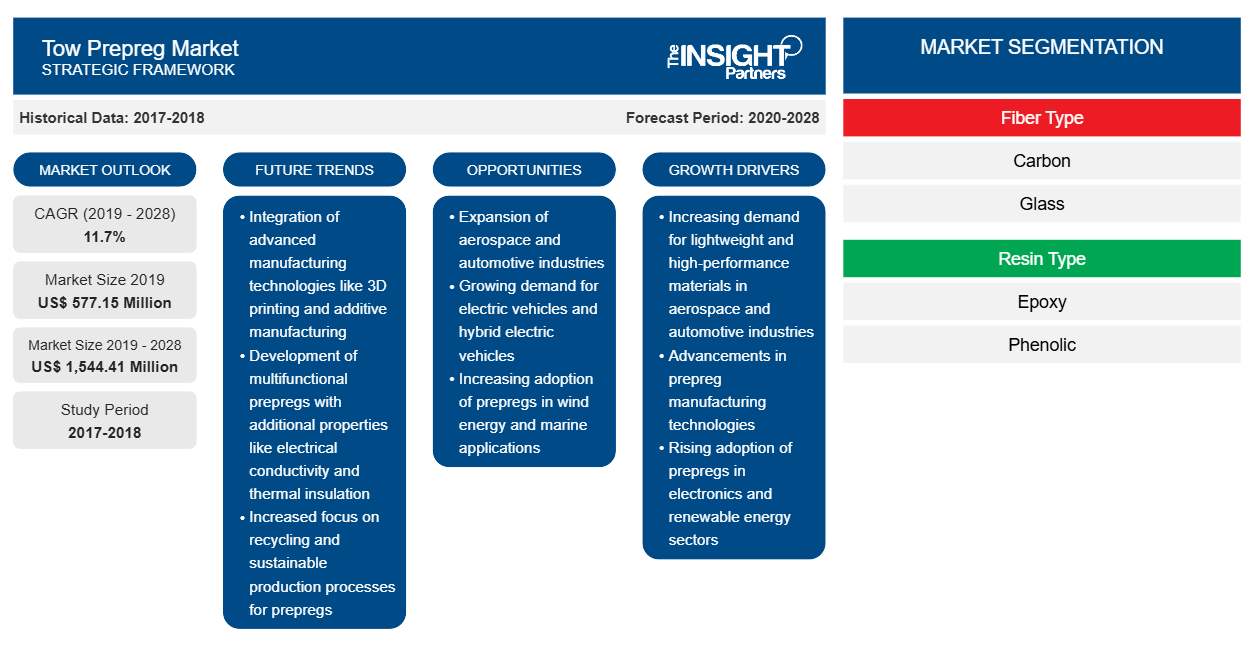

Asia Pacific is expected to become the fastest growing market in the global tow prepreg market in forecast period. The market growth tow prepreg in this region is primarily attributed to the presence of strong industrial base along with prominent manufactures significantly contributing to market growth. Further, the growth of automotive and transportation industry backed by the shift in living standards and high growth potential in China, India, and other such economies are significantly propelling the demand for tow prepreg. The rising foreign direct investments along with increasing manufacturing spending toward better product offerings offer lucrative opportunities for the market growth in Asia Pacific. The upsurge in the middle-class population along with growth in urbanization provides drives the growth of the tow prepreg market. The Asia Pacific manufacturing sector is rapidly adopting the innovative accelerators that include advanced technologies and processes. The easy accessibility and availability of raw materials, cheap labor, and low production cost accelerate the market growth in the region.

The COVID-19 has adversely affecting economies and industries in various countries due to government-imposed lockdowns, travel bans, and business shutdowns. The chemical & materials is one of the major industries suffering serious disruptions such as supply chain breaks, technology events cancellations, and office shutdowns. The shutdown of various plants and factories in North America, Europe, Asia Pacific, South America, and the Middle East and Africa has restricted the global supply chain and negatively impacted the manufacturing activities, delivery schedules, and product sales. Furthermore, various companies have already predicted possible delays in product deliveries and slump in future sales of their products. The travel bans imposed by countries in Europe, Asia, and North America are hindering the business collaborations and partnerships opportunities. All these factors are hampering the activities in the chemical & materials industry, which are restraining the growth of various markets related to this industry. Many countries are now resuming to normalcy, whereas many are experiencing second wave of the outbreak. In addition, due to vaccination drives, situations are changing now across the globe.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Tow Prepreg Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Tow Prepreg Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Market Insights

Surge in Demand for Lightweight and Cost-Efficient Materials

The demand for lightweight materials with high tensile strength is on the rise among several sectors, including automotive and transportation, aerospace, marine, and construction. The use of lightweight materials has a direct impact on the overall dynamics and structure of the components in which they are used. Tow Prepreg is one such compound material, which is preimpregnated with resin to increase its productivity and eliminate the use of resin coating. It is known to possess good elasticity, high dimensional stability, excellent mechanical and electrical properties, and strength. Lightweight nature and cost-efficiency make tow prepreg an ideal component across several application bases. The demand for tow prepreg compounds has considerably increased across various industries, owing to rise in advancements and innovations in these industries. Weight, along with strength, has become a significant factor for the performance of a vehicle. For instance, a slight reduction in the weight can improve the performance of a vehicle. This has offered a great opportunity for the growth of the tow prepreg market in global scenario. Composites have become a core strategic material for automotive and transportation Original Equipment Manufacturers (OEMs), as well as aerospace components. Moreover, the growing preference toward cost-effective composite materials in price-sensitive industries has motivated the prepreggers to adopt less costly but energy-intensive fiber precursors such as tow prepreg. All such factors are expected to boost the demand for tow prepreg.

Fiber Type Insights

The global Tow Prepreg market, by fiber type, is segmented into carbon, glass, and others. Carbon fiber tow is a thread utilized to weave carbon fiber fabrics. The carbon fiber tow prepreg is highly demanded from the end-use industries such as automotive & transportation, aerospace & defense, and sports & recreational sectors. This fiber has the highest strength modulus than the other fiber types. This tow prepreg also possesses high tensile strength & elastic modulus. Companies such as ENEOS Corporation are manufacturing and selling carbon fiber composite materials. Combining the independently developed resins along with pitch-fiber type & PAN-fiber type carbon fibers as well as the customer-requested fibers, including glass fibers & engineering plastic fibers, the company develops tow prepregs according to the needs of the customers.

Resin Type Insights

The global Tow Prepreg market, by resin type, is segmented into epoxy, phenolic and others. The epoxy segment led the market with the largest share in 2019. Epoxy compounds or glycidyl compounds comprise glycidyl esters, diglycidyl esters, and glycidyl amines as other fiber types of epoxy compounds, which are known as reactive diluents and are further added to basic resins to adjust performance features. Amongst various fiber types of epoxy resins produced, the diglycidyl ether of bisphenol-A (DGEBPA)-fiber type resins have gained prominence acceptance owing to their versatility. Epoxy possesses a robust structural length and a strong binding factor, which makes it a widely applicable element for filling up voids between the parts. An epoxy is composed of two parts that must be mixed approximately. Epoxies are available in various squeezing styles and different sizes. Different epoxies have multiple functions such as protective covering, filling, and mending. The function of the epoxy resin is to provide a strong binding characteristic to the epoxy tow prepreg composites. In addition, epoxy resin provides high tensile strength, wettability, high chemical and environmental resistance, strong adhesion, and better electrical properties.

End-Use Industry Insights

The global tow prepreg market, by end-use industry, is segmented into aerospace and defense, automotive and transportation, sports and recreational, oil and gas, and others. The aerospace and defense segment led the market with the largest share in 2019. A composite material typically consists of relatively strong and stiff fibers in a tough resin matrix. Innovative lightweight structures, along with highly complex aircraft components, are made of modern lightweight materials such as carbon fiber tow prepreg. Compared with conventional production technologies for various composite materials, this hybrid material also processes technology that obtains short cycle times, functional integration, optimum material usage, high freedom of design, and less rework. To produce the cabin, cargo, and other aircraft components, a direct implementation of metallic elements, including inserts, and the use of this composite can be realized. Furthermore, this process technology can be fully automated to yield an increased economic efficiency. Current composite aircraft interior components often use glass fiber/phenolic sandwich construction, characterized by low buy-to-fly material usage, high cycle times, and extensive rework/finishing.

A few key players operating in the global tow prepreg market are Mitsubishi Chemical Corporation; Hexcel Corporation.; Teijin Limited; Toray Industries Inc.; and SGL Carbon. Major market players are focused on strategies such as mergers and acquisitions, and product launches to increase their geographical presence and consumer base globally. For instance, in 2020, Mitsubishi Chemical Corporation announced the acquisition of a German Carbon Fiber Prepreg Manufacturer, c-m-p GmbH, which has excellent production technology of unidirectional/fabric prepreg and offers solutions to several markets, especially in the automotive and aerospace areas. By this acquisition, Mitsubishi Chemical Corporation will have prepreg factories in Europe, the US, and Japan.

Report Spotlights

- Progressive industry trends in the global tow prepreg market to help players develop effective long-term strategies

- Business growth strategies adopted by developed and developing markets

- Quantitative analysis of the market from 2017 to 2028

- Estimation of the demand for tow prepregs across various industries

- PEST analysis to illustrate the efficacy of buyers and suppliers operating in the industry to predict market growth

- Recent developments to understand the competitive market scenario and the demand for tow prepregs.

- Market trends and outlook coupled with factors driving and restraining the growth of the tow prepreg market.

- Decision-making process by understanding strategies that underpin commercial interest with regard to global tow prepreg market growth

- Tow prepreg market size at various nodes of market

- Detailed overview and segmentation of the global tow prepreg market as well as its dynamics in the industry

- Tow Prepreg market size in various regions with promising growth opportunities

Tow Prepreg Market Regional Insights

The regional trends and factors influencing the Tow Prepreg Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Tow Prepreg Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Tow Prepreg Market

Tow Prepreg Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2019 | US$ 577.15 Million |

| Market Size by 2028 | US$ 1,544.41 Million |

| Global CAGR (2019 - 2028) | 11.7% |

| Historical Data | 2017-2018 |

| Forecast period | 2020-2028 |

| Segments Covered |

By Fiber Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

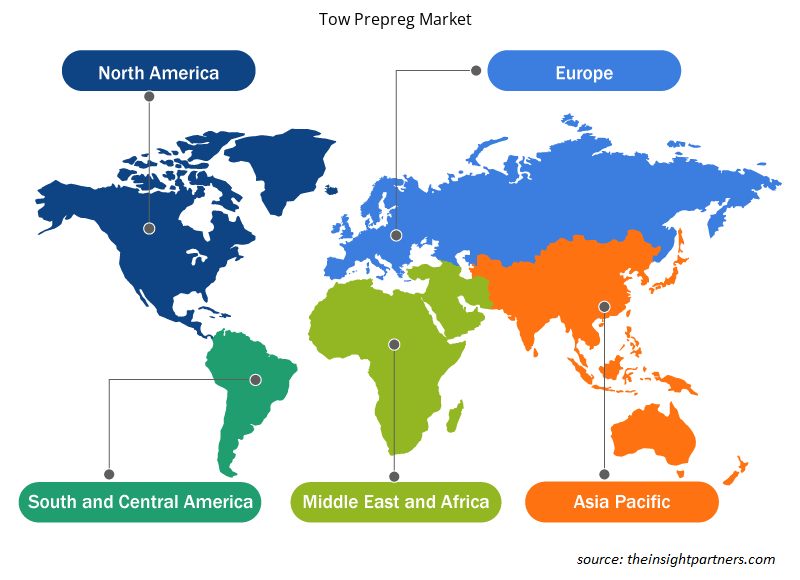

Tow Prepreg Market Players Density: Understanding Its Impact on Business Dynamics

The Tow Prepreg Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Tow Prepreg Market are:

- Arisawa Manufacturing Co., Ltd.

- Mitsubishi Chemical Corporation

- Red Composites Ltd

- SGL Carbon

- TCR Composites, Inc.

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Tow Prepreg Market top key players overview

Tow Prepreg Market, by Fiber Type

- Carbon

- Glass

- Others

Tow Prepreg Market, by Resin Type

- Epoxy

- Phenolic

- Others

Tow Prepreg Market, by End-Use Industry

- Aerospace and Defense

- Automotive and Transportation

- Sports and Recreational

- Oil and Gas

- Others

Company Profiles

- Arisawa Manufacturing Co., Ltd.

- Mitsubishi Chemical Corporation

- Red Composites Ltd

- SGL Carbon

- TCR Composites, Inc.

- Teijin Limited

- ENEOS Corporation

- HEXCEL CORPORATION

- PORCHER INDUSTRIES

- TORAY INDUSTRIES, INC.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Fiber Type , Resin Type , and End-Use Industry

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

Argentina, Australia, Brazil, Canada, China, France, Germany, India, Italy, Japan, Mexico, Saudi Arabia, South Africa, South Korea, United Arab Emirates, United Kingdom, United States

Frequently Asked Questions

The automotive and transportation industry segment is the fastest growing segment in the global tow prepregs market for the forecasted period. The growth of the segment is attributable to surging demand of improved materials with environment friendliness and cost-efficiency. With the expansion in the automotive and transportation industry, the demand for prepregs is set to rise. For instance, companies such as Ford Motor Co. are deploying the use of prepregs and other materials to produce rear suspension knuckle. Hence, with the rise in demand for prepregs, manufacturers have come up better form of precursors such as tow prepreg and others. These fiber precursors are preferred over other traditional materials owing to their properties such as tensile strength along with limited curing time, uniformity and consistency, lightweight, better friction, and others, which make them ideal to be used across various applications in automotive and transportation industry. Moreover, they can ideally be used to suit the dynamic requirements of the processing industry.

The major players operating in the global tow prepreg market are Arisawa Manufacturing CO., LTD.; Eneos Corporation; Hexcel Corporation; Mitsubishi Chemical Corporation; Porcher Industries; Red Composites LTD; SGL Carbon; TCR Composites, Inc.; Teijin Limited; Toray Industries, Inc. among many others.

Asia Pacific is expected to fastest growing market in the global tow prepregs market in forecasted period. The growth of the tow prepregs market in this region is primarily attributed to the presence of strong industrial base along with prominent manufactures significantly contributing to market growth. Further, the growth of automotive and transportation industry backed by shift in living standards and high growth potential in China, India, and other such economies, which are significantly contributing to surge in demand for tow prepregs. The region encompasses an ample amount of opportunities for the growth of the market attributable to the rise in foreign direct investments along with rise in manufacturing spending towards better product offerings. The upsurge in the middle-class population along with growth in urbanization provides impetus for the growth of the tow prepregs market. The Asia Pacific manufacturing sector is rapidly adopting the innovation accelerators that include advanced technologies and processes. The easy accessibility and availability of raw materials coupled with cheap labor and low production cost are yet another factor that bode well the market demand in the region.

Trends and growth analysis reports related to Chemicals and Materials : READ MORE..

The List of Companies - Tow Prepreg Market

- Arisawa Manufacturing Co., Ltd.

- Mitsubishi Chemical Corporation

- Red Composites Ltd

- SGL Carbon

- TCR Composites, Inc.

- Teijin Limited

- ENEOS Corporation

- HEXCEL CORPORATION

- PORCHER INDUSTRIES

- TORAY INDUSTRIES, INC.

Get Free Sample For

Get Free Sample For