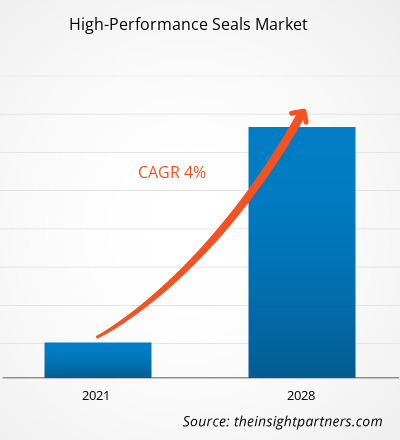

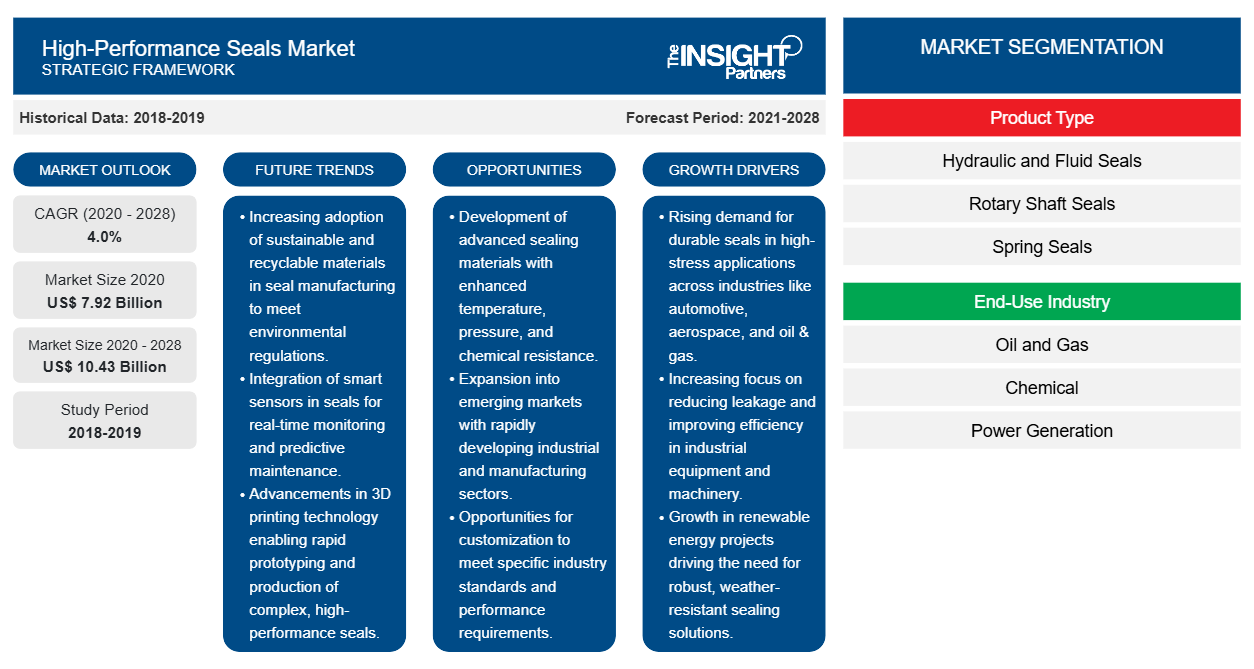

2020 年高性能密封件市场价值为 79.2082 亿美元,预计到 2028 年将达到 104.2616 亿美元;预计 2021 年至 2028 年的复合年增长率为 4.0%。

高性能密封件用于高压气体和液体化学品,以承受机械变形。密封件采用机械加工或模压而成,并使用复杂的模拟软件精心设计。密封件由各种材料制成,例如聚氨酯、橡胶或聚四氟乙烯 (PTFE)。高性能密封件有多种类型,例如液压密封件、旋转轴密封件、油封、填料、垫圈和其他高性能橡胶和塑料部件。高性能密封件具有很强的耐流体、耐热和耐磨性。高性能密封件被各种终端用户行业广泛使用,例如化工、汽车、石油和天然气、航空航天和国防、制药、建筑等。

预计在预测期内,亚太地区的高性能密封件市场将以最高的复合年增长率增长。该地区市场的增长主要归因于化学品、汽车、石油和天然气以及航空航天和国防等因素。由于工业快速发展,外国直接投资大幅增加,以及研发活动支出增加,该地区为市场增长提供了充足的机会。这些因素有望使高性能密封件的应用基础多样化,并推动市场增长。此外,在经济活动改善和投资机会改善的支持下,制造业基地的快速发展正在促进亚太市场高性能密封件的增长。中国在区域市场占据主导地位,其次是日本、印度和韩国等其他国家。

定制此报告以满足您的需求

您可以免费定制任何报告,包括本报告的部分内容、国家级分析、Excel 数据包,以及为初创企业和大学提供优惠和折扣

- 获取此报告的关键市场趋势。这个免费样品将包括数据分析,从市场趋势到估计和预测。

COVID-19 疫情对高性能密封件市场的影响

持续的疫情彻底改变了工业部门的现状,并对高性能密封件市场的增长产生了负面影响。由于国家和国际边界突然关闭,石油和天然气、化工、发电、航空航天和国防、制药、半导体、汽车、食品和饮料等行业都受到了运营效率突然扭曲和价值链中断的影响。例如,根据《航空制造杂志》 2021 年 1 月发表的一篇文章,飞机交付量与上一年相比下降了 54%。同样,国际金融公司强调,发电行业的增长也受到疫情的影响,导致需求减少、财务压力和电力供应链中断。多个工业部门增长大幅下降,对全球市场对高性能密封件的需求产生了负面影响。原材料供应商采购严重中断,以及无限期封锁和临时隔离导致制造基地暂时关闭,影响了市场的增长。不过,随着各经济体计划恢复运营,全球对高性能密封件的需求预计将上升。

市场洞察

汽车行业对高性能密封件的需求不断增长,推动高性能密封件市场增长

汽车制造商需要新的创新高性能材料来制造汽车零部件。由于快速的城市化、可支配收入的增加以及消费者生活方式的转变,全球汽车行业正在经历巨大的变革。此外,全球化的积极影响、发展中经济体制造能力的提高以及先进技术的采用都是推动乘用车和商用车需求的因素之一。根据经济学人智库有限公司的数据,到 2021 年底,新车销量预计将增长 15%,其中商用车销量到 2021 年可能会增长 16%。高性能密封件广泛应用于各种汽车应用,如空调系统、汽车电池、制动系统、电子控制单元、燃油系统和行驶控制系统。因此,汽车销量的上升推动了对汽车零部件中使用的高性能密封材料的需求。

高性能密封件可承受长途行驶中的高温。此外,严格的碳排放法规的实施促使制造商遵守规范,以帮助最大限度地减少排放和意外停机风险,这进一步推动了对此类密封件的需求。

产品类型洞察

根据产品类型,高性能密封件市场细分为液压和流体密封件、旋转轴密封件、弹簧密封件、油田密封件、泵密封件等。液压和流体密封件部分在 2020 年占据了最大的市场份额,预计在预测期内将实现最高的复合年增长率。液压密封件用于液压缸中,以密封气缸各个部件之间的开口。密封件采用机械加工或模制而成,并利用先进的模拟工具精心设计。液压密封件由聚氨酯、橡胶或聚四氟乙烯 (PTFE) 等多种材料制成。这些密封件具有很强的耐流体、耐热和耐磨性。液压密封件的主要任务是保留液压油、保持杆和活塞对齐、排除固体或液体污染物以及保持液压。它们用于各种终端行业,例如航空航天、汽车、农业、建筑、石油和天然气、海洋和化学品。

最终用途行业洞察

根据最终用途行业,高性能密封件市场细分为石油和天然气、化工、发电、航空航天和国防、制药、汽车、食品和饮料等。化工领域在 2020 年占据了最大的市场份额,预计石油和天然气领域在预测期内的复合年增长率最高。高性能密封件用于各种化学加工应用,例如密封泵、阀门、储罐和流体计量装置。化学工业由各种工艺和材料组成,需要量身定制的密封解决方案。这些密封件可确保没有任何有害物质渗入工艺中。工业中使用的密封件可以由聚四氟乙烯 (PTFE)、全氟弹性体和乙烯丙烯二烯单体 (EPDM) 等高质量材料制成。化学工业中使用的高性能密封件需要对各种腐蚀性介质具有出色的耐化学性、耐高低温极端温度以及强大的机械强度。因此,密封系统的可靠性是保证生产程序以完全安全的方式运行的重中之重。

高性能密封件市场中的少数参与者包括 AFT Fluorotec、American High Performance Seals、ElringKlinger Kunststofftechnik GmbH、High Performance Seals、James Walker、Mykin Inc.、Performance Seals, Inc.、PXL SEALS、Precision Polymer Engineering Limited 和 Trelleborg Sealing Solutions。主要公司实施并购和研发战略,以扩大客户群并在全球市场中获得显著份额,这也使他们能够在全球范围内保持自己的品牌名称。

报告亮点

- 高性能密封件市场的渐进式行业趋势可帮助参与者制定有效的长期战略

- 发达市场和发展中市场采用的业务增长战略

- 2019 年至 2028 年高性能密封件市场定量分析

- 全球高性能密封件需求量估计

- PEST 分析可说明行业内买家和供应商的效率

- 了解竞争市场状况的最新发展

- 市场趋势和前景以及推动和抑制高性能密封件市场增长的因素

- 通过强调支撑商业利益的市场策略来协助决策过程,从而促进市场增长

- 高性能密封件市场规模在不同节点的大小

- 市场的详细概述和细分,以及高性能密封件行业动态

- 各地区高性能密封件市场规模及增长潜力

高性能密封件

高性能密封件市场区域洞察

Insight Partners 的分析师已详尽解释了预测期内影响高性能密封件市场的区域趋势和因素。本节还讨论了北美、欧洲、亚太地区、中东和非洲以及南美和中美洲的高性能密封件市场细分和地理位置。

- 获取高性能密封件市场的区域特定数据

高性能密封件市场报告范围

| 报告属性 | 细节 |

|---|---|

| 2020 年市场规模 | 79.2亿美元 |

| 2028 年市场规模 | 104.3亿美元 |

| 全球复合年增长率(2020 - 2028) | 4.0% |

| 史料 | 2018-2019 |

| 预测期 | 2021-2028 |

| 涵盖的领域 | 按产品类型

|

| 覆盖地区和国家 | 北美

|

| 市场领导者和主要公司简介 |

|

高性能密封件市场参与者密度:了解其对业务动态的影响

高性能密封件市场正在快速增长,这得益于最终用户需求的不断增长,这些需求源于消费者偏好的不断变化、技术进步以及对产品优势的认识不断提高等因素。随着需求的增加,企业正在扩大其产品范围,进行创新以满足消费者的需求,并利用新兴趋势,从而进一步推动市场增长。

市场参与者密度是指在特定市场或行业内运营的企业或公司的分布情况。它表明相对于给定市场空间的规模或总市场价值,有多少竞争对手(市场参与者)存在于该市场空间中。

在高性能密封件市场运营的主要公司有:

- AFT 氟技术

- 美国高性能密封件

- 爱尔铃克林格塑料技术有限公司

- 高性能密封件

- 詹姆斯·沃克

免责声明:上面列出的公司没有按照任何特定顺序排列。

- 了解高性能密封件市场的主要参与者概况

高性能密封件市场 – 按产品类型划分

- 液压和流体密封件

- 旋转轴密封件

- 弹簧密封件

- 油田密封件

- 泵密封件

- 其他的

高性能密封件市场 – 按最终用途行业划分

- 航空航天和国防

- 汽车

- 石油和天然气

- 化学

- 发电

- 制药

- 食品和饮料

- 其他的

公司简介

- AFT 氟技术

- 美国高性能密封件

- 爱尔铃克林格塑料技术有限公司

- 高性能密封件

- 詹姆斯·沃克

- Mykin 公司

- 性能密封件有限公司

- PXL 密封件

- 精密聚合物工程有限公司

- 特瑞堡密封系统

- 历史分析(2 年)、基准年、预测(7 年)及复合年增长率

- PEST和SWOT分析

- 市场规模、价值/数量 - 全球、区域、国家

- 行业和竞争格局

- Excel 数据集

近期报告

相关报告

客户评价

购买理由

- 明智的决策

- 了解市场动态

- 竞争分析

- 客户洞察

- 市场预测

- 风险规避

- 战略规划

- 投资论证

- 识别新兴市场

- 优化营销策略

- 提升运营效率

- 顺应监管趋势

获取免费样品 - 高性能密封件市场

获取免费样品 - 高性能密封件市场