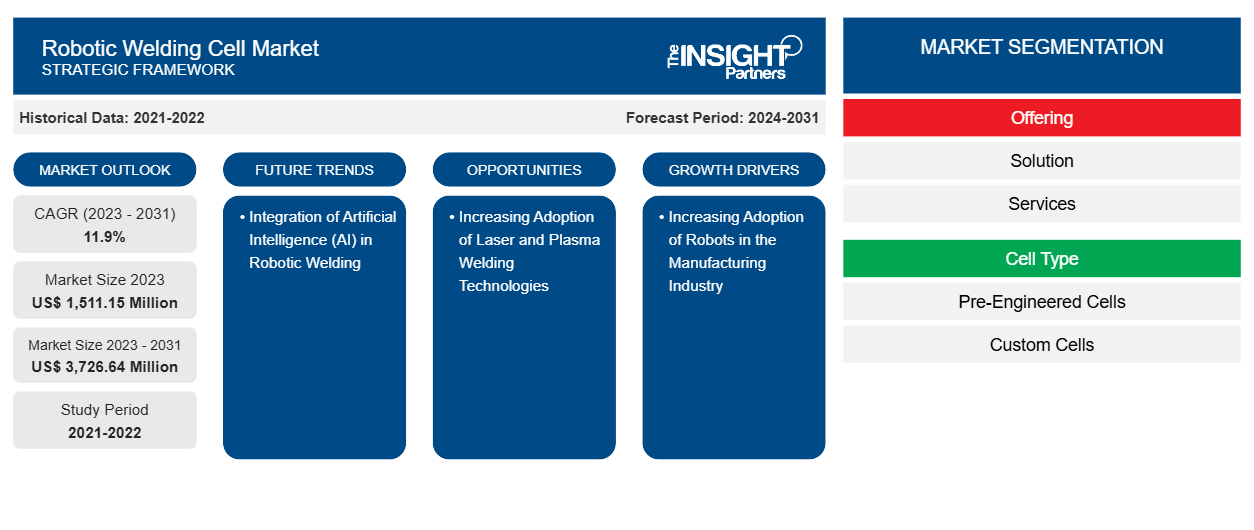

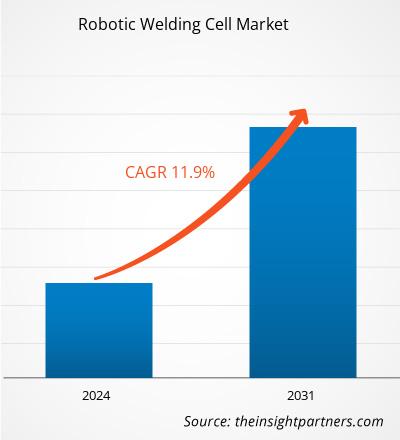

机器人焊接单元市场规模预计将从 2023 年的 15.1115 亿美元增至 2031 年的 37.2664 亿美元。预计 2023-2031 年期间市场复合年增长率将达到 11.9%。工业 4.0 技术的日益普及可能会在未来几年为市场带来新的关键趋势。

机器人焊接单元市场分析

机器人焊接单元由多个组件组成,它们协同工作以焊接零件。机器人焊接单元提供世界一流的焊接操作,并按照全球标准设计,以节省操作员的成本和时间。预制单元是具有成本效益的机器人焊接单元,仅包含焊接过程所需的基本必要组件。这种单元的基本结构可以快速安装;它允许制造商缩短单元生产时间并尽早交付最终产品。与预制单元相比,定制单元价格昂贵,因为它们包括独特设备以及基本必要组件。这些主要是根据客户的特定兴趣制造的。因此,制造和交付定制机器人焊接单元所需的时间比预制单元更长。焊接机器人广泛应用于汽车行业。对汽车的需求正在显着增加。消费者支出的增加是推动全球(尤其是亚洲国家)对汽车需求的因素之一。根据国际汽车制造商组织 (International Organization of Motor Vehicle Manufacturers) 在 2024 年发布的数据,2023 年汽车总产量将达到 9300 万辆,比 2021 年到 2023 年增长 12%。新工厂建设的增加导致这些新汽车工厂对焊接机器人的需求增加,最终推动了机器人焊接单元市场的发展。

机器人焊接单元市场概况

全球机器人焊接单元市场生态系统的主要利益相关者包括原材料/组件供应商、机器人焊接单元制造商、政府组织、监管机构和最终客户。组件和硬件供应商为机器人焊接单元制造商提供各种组件和零件。本报告中涉及的主要机器人焊接单元制造商包括 Abb Ltd、Acieta LLC、Carl Cloos Schweisstechnik Gmbh、川崎重工有限公司、库卡股份公司、Phoenix Industrial Solutions、林肯电气公司、Wec Group Ltd. 和安川美国公司等。在机器人焊接单元制造商之后,全球机器人焊接单元市场还有几个外围利益相关者,他们在推动机器人焊接单元的技术进步和采用方面发挥着至关重要的作用。

定制此报告以满足您的需求

您可以免费定制任何报告,包括本报告的部分内容、国家级分析、Excel 数据包,以及为初创企业和大学提供优惠和折扣

- 获取此报告的关键市场趋势。这个免费样品将包括数据分析,从市场趋势到估计和预测。

机器人焊接单元市场驱动因素和机遇

制造业越来越多地采用机器人

机器人在制造业中发挥着重要作用。机器人有助于提高生产操作的整体效率和生产力。它们在制造业中用于各种应用,例如装配和分配、搬运和拾取、加工和切割、焊接和焊接、铸造和成型、精加工和打磨、喷漆和涂层、清洁和卫生、物流和仓储以及包装和码垛。根据国际机器人联合会 2024 年发布的数据,2023 年全球工厂中约有 420 万台机器人在运行,比 2022 年的 390 万台有所增加。根据国际机器人联合会 2021 年的数据,工厂中工作的机器人总数中有一半将用于焊接应用。因此,制造业越来越多地采用机器人,推动了机器人焊接单元市场的增长。

激光和等离子焊接技术的应用日益广泛

激光焊接的需求正在迅速增加。激光焊接技术使用二氧化碳、氮气和氦气产生的高能激光束。这有助于以高精度和高速度连接材料。由于变形最小且能够焊接不同材料,激光焊接的普及度正在提高。此外,通过提高激光效率和优化焊接工艺,这种焊接技术可以实现整体节能。这是增加激光焊接需求的重要因素之一,因为减少能源消耗是全球主要关注点之一。

此外,当与 AI 和 ML 等先进技术相结合时,这种焊接技术可以高效运行。因此,对激光焊接技术的需求正在显着增加。同样,等离子焊接技术具有多种优势,包括高功率密度、焊缝干净光滑、焊接速度快、变形小和间隙桥接改善。通过等离子焊接产生的焊缝非常牢固且不太明显。

机器人焊接单元市场报告细分分析

有助于得出机器人焊接单元市场分析的关键部分是产品供应、单元类型和最终用途行业。

- 根据产品,全球机器人焊接单元市场分为解决方案和服务。解决方案部分在 2023 年占据了更大的市场份额,预计在预测期内将实现更高的复合年增长率。机器人焊接单元解决方案可帮助制造商实现额外的生产能力并缓解劳动力短缺问题。机器人焊接单元相对于手动焊接工艺的这些优势正在推动对机器人焊接单元的需求。

- 根据单元类型,全球机器人焊接单元市场细分为预制单元和定制单元。预制单元部分在单元类型部分中占据主导地位,2023 年的市场份额为 68.3%,而定制单元部分预计在预测期内将实现更高的复合年增长率。预制机器人焊接单元是标准的机器人焊接单元,具有更大的工作空间、更长的机器人操纵器和两个更大的桌面。另一方面,定制单元是根据最终用户的要求制造的,并针对特定行业进行定制。

- 根据最终用途行业,全球机器人焊接单元市场细分为汽车、制造业、航空航天和国防。汽车行业占据第二大市场份额,预计在预测期内将录得最高增长率。推动汽车行业需求的因素之一是全球汽车产量和销量的增加。制造业预计在预测期内将录得显着的复合年增长率。推动制造业对机器人焊接单元需求的因素之一是全球工业化趋势的增强,尤其是在发展中国家。

机器人焊接单元市场份额分析

机器人焊接单元市场报告的地理范围提供了详细的区域和国家分析。北美、欧洲和亚太地区是机器人焊接单元市场显着增长的主要地区。中国在 2022 年机器人安装总数中占据了近 60% 的市场份额。中国在 2022 年安装了约 0.2 百万台机器人,而日本在 2022 年安装了超过 50,000 台机器人,是全球第二大市场。除中国和日本外,新加坡、印度和泰国也是亚太地区的几个主要市场。

欧洲在工业机器人安装和机器人焊接单元行业中占据第二大市场份额。2023 年,德国是欧洲最大的机器人焊接单元和工业机器人市场。推动机器人焊接单元需求的因素之一是德国注重增加对工业 4.0 技术的采用。德国、法国、英国和意大利在机器人焊接单元市场中占有显著份额。

北美是机器人焊接单元的主要市场之一,因为该地区拥有一些跨行业的重要制造公司,对工业 4.0 的需求不断增加,对先进技术的需求也在增加。由于美国的工业化和数字化趋势,美国占据了最大的市场份额。此外,美国还拥有一些主要的汽车和航空航天制造公司,例如特斯拉、波音和福特汽车。

机器人焊接单元市场区域洞察

Insight Partners 的分析师已详细解释了预测期内影响机器人焊接单元市场的区域趋势和因素。本节还讨论了北美、欧洲、亚太地区、中东和非洲以及南美和中美洲的机器人焊接单元市场细分和地理位置。

- 获取机器人焊接单元市场的区域特定数据

机器人焊接单元市场报告范围

| 报告属性 | 细节 |

|---|---|

| 2023 年的市场规模 | 15.1115亿美元 |

| 2031 年市场规模 | 37.2664亿美元 |

| 全球复合年增长率(2023 - 2031) | 11.9% |

| 史料 | 2021-2022 |

| 预测期 | 2024-2031 |

| 涵盖的领域 | 通过奉献

|

| 覆盖地区和国家 | 北美

|

| 市场领导者和主要公司简介 |

|

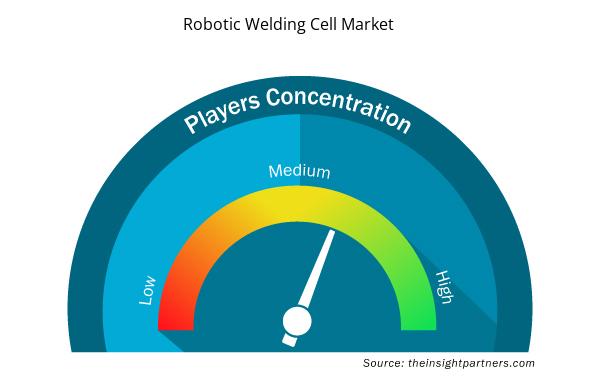

机器人焊接单元市场参与者密度:了解其对业务动态的影响

机器人焊接单元市场正在快速增长,这得益于终端用户需求的不断增长,而这些需求又源于消费者偏好的不断变化、技术进步以及对产品优势的认识不断提高等因素。随着需求的增加,企业正在扩大其产品范围,进行创新以满足消费者的需求,并利用新兴趋势,从而进一步推动市场增长。

市场参与者密度是指在特定市场或行业内运营的企业或公司的分布情况。它表明在给定市场空间中,相对于其规模或总市场价值,有多少竞争对手(市场参与者)存在。

在机器人焊接单元市场运营的主要公司有:

- ABB有限公司

- 阿西埃塔

- 卡尔·克鲁斯施魏斯技术有限公司

- 林肯电气控股公司

- 库卡公司

- 川崎重工业公司

免责声明:上面列出的公司没有按照任何特定顺序排列。

- 获取机器人焊接单元市场顶级关键参与者概述

机器人焊接单元市场新闻和最新发展

通过收集主要和次要研究后的定性和定量数据来评估机器人焊接单元市场,其中包括重要的公司出版物、协会数据和数据库。下面列出了机器人焊接单元市场的一些发展:

- ABB 的新型 OmniVance FlexArc Compact 单元节省了空间并为焊接应用增加了灵活性。ABB Ltd. 推出了 OmniVance FlexArc Compact,这是一款新型、更小的焊接应用单元,具有更大的灵活性、易用性和更好的集成性,可帮助企业解决焊接劳动力短缺问题。OmniVance FlexArc Compact 是同类产品中最小的弧焊单元。其创新的 45 度龙门机器人安装设计通过将机器人放置在三轴转盘的中心,使其更靠近工件,最大限度地提高了机器人的工作参数。(ABB Ltd.,公司网站,2022 年 6 月)

机器人焊接单元市场报告覆盖范围和交付成果

“机器人焊接单元市场规模和预测(2021-2031)”报告对以下领域进行了详细的市场分析:

- 机器人焊接单元市场规模以及范围内所有主要细分市场在国家层面的预测

- 机器人焊接单元市场趋势,以及驱动因素、限制因素和关键机遇等市场动态

- 详细的 PEST 和 SWOT 分析

- 机器人焊接单元市场分析涵盖主要市场趋势、国家框架、主要参与者、法规和最新市场发展

- 行业格局和竞争分析,涵盖市场集中度、热图分析、知名参与者以及机器人焊接单元市场的最新发展

- 详细的公司简介

- 历史分析(2 年)、基准年、预测(7 年)及复合年增长率

- PEST 和 SWOT 分析

- 市场规模价值/数量 - 全球、区域、国家

- 行业和竞争格局

- Excel 数据集

- Dropshipping Market

- Military Rubber Tracks Market

- Batter and Breader Premixes Market

- Queue Management System Market

- Long Read Sequencing Market

- Small Internal Combustion Engine Market

- Aircraft Landing Gear Market

- Integrated Platform Management System Market

- Third Party Logistics Market

- Digital Pathology Market

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

This text is related

to segments covered.

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

This text is related

to country scope.

常见问题

Rising integration of artificial Intelligence (AI) in robotic welding is major trend in the market. Artificial intelligence (AI) and machine learning (ML) are being adopted in almost all industries, including the welding industry. By leveraging AI, welding systems can be made smarter and adaptable. Some of the key areas where AI integration is beneficial are weld defect detection, adaptive welding, and path planning. One of the key factors in the welding process is ensuring quality control. Defects in the welded area lead to high risks in the overall strength and safety of the final product. Integration of AI and ML, along with advanced vision systems, can be used for defect detection in real-time. This technology can be used to detect various types of defects, such as cracks, incomplete welding, and porosity. In addition, as this technology continuously gathers data from the system in real-time, AI and ML can learn and improve the process by analysing real-time and historical data.

The robotic welding cell market was valued at US$ 1,511.15 million in 2023 and is projected to reach US$ 3,726.64 million by 2031; it is expected to register a CAGR of 11.9% during 2023–2031.

The demand for robotics across the globe is growing notably owing to factors such as digitalization, rising trends of automation, increased need for higher efficiency, and availability of innovative technology. These are some of the factors that are driving the demand for industrial robots, ultimately robotic welding cells across the globe. According to the data provided in the World Robotics Report 2023, 0.55 million industrial robots were installed worldwide in 2022.

The key players operating in the robotic welding cell market include Abb Ltd, Acieta LLC, Carl Cloos Schweisstechnik Gmbh, Kawasaki Heavy Industries, Ltd; Kuka AG; Phoenix Industrial Solutions; The Lincoln Electric Company; Wec Group Ltd.; Yaskawa America, Inc.; among others.

Asia Pacific is anticipated to have largest share in robotic welding cell market.

The solution segment led the robotic welding cell market with a significant share in 2023.

The robotic welding cell market is expected to reach US$ 3,726.64 million by 2031.

Trends and growth analysis reports related to Manufacturing and Construction : READ MORE..

The List of Companies - Robotic Welding Cell Market

- ABB Ltd.

- Acieta

- Carl Cloos Schweisstechnik GmbH

- Lincoln Electric Holdings Inc.

- Kuka AG

- Kawasaki Heavy Industries Ltd.

- Phoenix Industrial Solutions

- WEC Group Ltd.

- Yaskawa America Inc

- Zeman Bauelemente Produktionsgesellschaft GmbH

- Fanuc Corp.

- Fronius International GmbH

- ESABB

- OTC-DAIHEN

- Kemppi Oy

- Panasonic Holdings Corp.

- Universal Robots AS.

The Insight Partners performs research in 4 major stages: Data Collection & Secondary Research, Primary Research, Data Analysis and Data Triangulation & Final Review.

- Data Collection and Secondary Research:

As a market research and consulting firm operating from a decade, we have published and advised several client across the globe. First step for any study will start with an assessment of currently available data and insights from existing reports. Further, historical and current market information is collected from Investor Presentations, Annual Reports, SEC Filings, etc., and other information related to company’s performance and market positioning are gathered from Paid Databases (Factiva, Hoovers, and Reuters) and various other publications available in public domain.

Several associations trade associates, technical forums, institutes, societies and organization are accessed to gain technical as well as market related insights through their publications such as research papers, blogs and press releases related to the studies are referred to get cues about the market. Further, white papers, journals, magazines, and other news articles published in last 3 years are scrutinized and analyzed to understand the current market trends.

- Primary Research:

The primarily interview analysis comprise of data obtained from industry participants interview and answers to survey questions gathered by in-house primary team.

For primary research, interviews are conducted with industry experts/CEOs/Marketing Managers/VPs/Subject Matter Experts from both demand and supply side to get a 360-degree view of the market. The primary team conducts several interviews based on the complexity of the markets to understand the various market trends and dynamics which makes research more credible and precise.

A typical research interview fulfils the following functions:

- Provides first-hand information on the market size, market trends, growth trends, competitive landscape, and outlook

- Validates and strengthens in-house secondary research findings

- Develops the analysis team’s expertise and market understanding

Primary research involves email interactions and telephone interviews for each market, category, segment, and sub-segment across geographies. The participants who typically take part in such a process include, but are not limited to:

- Industry participants: VPs, business development managers, market intelligence managers and national sales managers

- Outside experts: Valuation experts, research analysts and key opinion leaders specializing in the electronics and semiconductor industry.

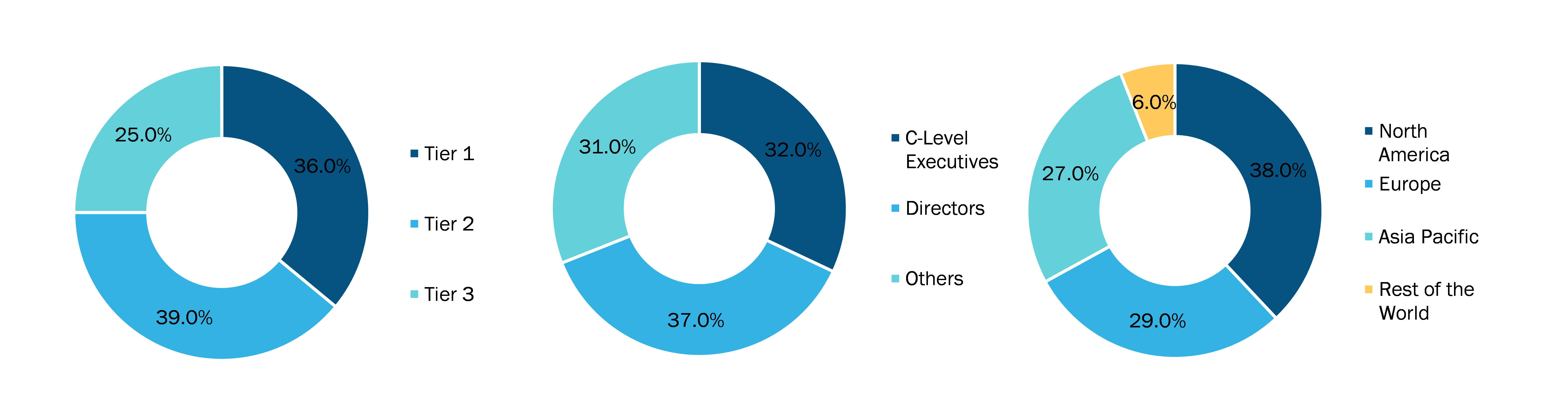

Below is the breakup of our primary respondents by company, designation, and region:

Once we receive the confirmation from primary research sources or primary respondents, we finalize the base year market estimation and forecast the data as per the macroeconomic and microeconomic factors assessed during data collection.

- Data Analysis:

Once data is validated through both secondary as well as primary respondents, we finalize the market estimations by hypothesis formulation and factor analysis at regional and country level.

- Macro-Economic Factor Analysis:

We analyse macroeconomic indicators such the gross domestic product (GDP), increase in the demand for goods and services across industries, technological advancement, regional economic growth, governmental policies, the influence of COVID-19, PEST analysis, and other aspects. This analysis aids in setting benchmarks for various nations/regions and approximating market splits. Additionally, the general trend of the aforementioned components aid in determining the market's development possibilities.

- Country Level Data:

Various factors that are especially aligned to the country are taken into account to determine the market size for a certain area and country, including the presence of vendors, such as headquarters and offices, the country's GDP, demand patterns, and industry growth. To comprehend the market dynamics for the nation, a number of growth variables, inhibitors, application areas, and current market trends are researched. The aforementioned elements aid in determining the country's overall market's growth potential.

- Company Profile:

The “Table of Contents” is formulated by listing and analyzing more than 25 - 30 companies operating in the market ecosystem across geographies. However, we profile only 10 companies as a standard practice in our syndicate reports. These 10 companies comprise leading, emerging, and regional players. Nonetheless, our analysis is not restricted to the 10 listed companies, we also analyze other companies present in the market to develop a holistic view and understand the prevailing trends. The “Company Profiles” section in the report covers key facts, business description, products & services, financial information, SWOT analysis, and key developments. The financial information presented is extracted from the annual reports and official documents of the publicly listed companies. Upon collecting the information for the sections of respective companies, we verify them via various primary sources and then compile the data in respective company profiles. The company level information helps us in deriving the base number as well as in forecasting the market size.

- Developing Base Number:

Aggregation of sales statistics (2020-2022) and macro-economic factor, and other secondary and primary research insights are utilized to arrive at base number and related market shares for 2022. The data gaps are identified in this step and relevant market data is analyzed, collected from paid primary interviews or databases. On finalizing the base year market size, forecasts are developed on the basis of macro-economic, industry and market growth factors and company level analysis.

- Data Triangulation and Final Review:

The market findings and base year market size calculations are validated from supply as well as demand side. Demand side validations are based on macro-economic factor analysis and benchmarks for respective regions and countries. In case of supply side validations, revenues of major companies are estimated (in case not available) based on industry benchmark, approximate number of employees, product portfolio, and primary interviews revenues are gathered. Further revenue from target product/service segment is assessed to avoid overshooting of market statistics. In case of heavy deviations between supply and demand side values, all thes steps are repeated to achieve synchronization.

We follow an iterative model, wherein we share our research findings with Subject Matter Experts (SME’s) and Key Opinion Leaders (KOLs) until consensus view of the market is not formulated – this model negates any drastic deviation in the opinions of experts. Only validated and universally acceptable research findings are quoted in our reports.

We have important check points that we use to validate our research findings – which we call – data triangulation, where we validate the information, we generate from secondary sources with primary interviews and then we re-validate with our internal data bases and Subject matter experts. This comprehensive model enables us to deliver high quality, reliable data in shortest possible time.

获取此报告的免费样本

获取此报告的免费样本